| SKU | 7010366209 |

|---|---|

| Legacy SKU | 61500124856 |

| UPC | 00048011196039 |

| Product Number | X2-WL |

Scotch-Brite EX2 Deburring Wheel is a convolute-constructed wheel that provides mid-range aggressiveness and hardness for deburring, edge radius, blending, polishing, and finishing. This deburring wheel performs best when consistently presented with a sharp edge or metal burrs.

- Wheel edge can be dressed for effective deburring, finishing and polishing of all metal alloys and many plastics and composites

- Tough, layered, unitized construction can operate clockwise or counterclockwise directions

- Densities and grades ranging from soft and conformable to hard and aggressive offer utility for a wide variety of applications

- Resists smearing for cleaner surfaces and less preparation

- Minimizes heat build up to lessen impact on heat-sensitive materials

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 8 in | 203.2 mm |

| Center Hole Diameter | 3 in | 76.2 mm |

Shipping Dimensions |

|

| Weight | 5.73202 lb |

|---|---|

| Length | 8.70079 in |

| Width | 8.50394 in |

| Height | 4.84252 in |

| Color | Gray |

|---|---|

| Maximum Speed | 4,500 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ EX2 Deburring Wheel?

The Scotch-Brite™ EX2 Deburring Wheel is a non-woven abrasive wheel designed for consistent edge deburring and finishing.

-

What are the specifications of this particular wheel (X2-WL, 9S Fine, 8 in x 2 in x 3 in, 2 ea/Case)?

This particular deburring wheel has a grade of fine (9S), measures 8 inches in diameter by 2 inches wide with a bore diameter of three inches. Each case contains two wheels.

-

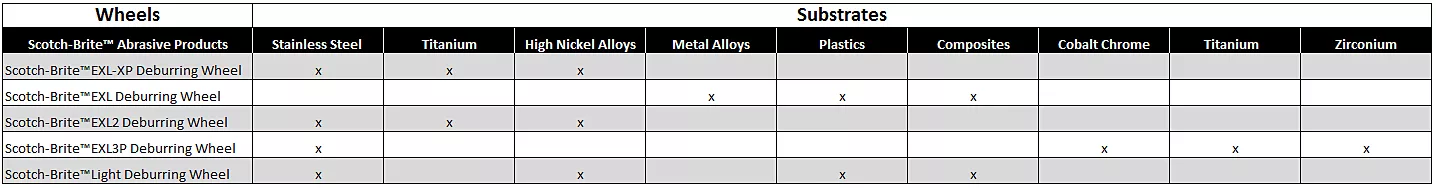

What materials can be used with this deburring wheel?

The Scotch-Brite™ EX2 Deburring Wheel can be effectively used on many different types of metals including aluminum, titanium, nickel alloys as well as other non-metallic materials such as ceramics and plastics.

-

How does this product work?

The durable open web construction makes it easy to clean and reuse each individual cell; so instead of quick clogs or loading up quickly due to accumulation on what's being removed like some bonded abrasives might experience over repeated use… the coating on our discs debris sheds frequently keeping usable cells exposed allowing for residues to continue removal without interruption.

-

. Why should I choose the Scotch-Brite™ EX2 Deburring Wheel over other abrasive options?

. The Scotch-Brite™ EX2 Deburring Wheel offers excellent consistency and control during use resulting in no defects on finished parts compared to traditional grinding where important burrs must be avoided at cost like altering shapes or ruining component functionality altogether!

The Scotch-Brite™ EX2 Deburring Wheel is a high-performance wheel that combines mineral and density to provide a moderate degree of conformability, wheel hardness, and edge retention. The wheel is uniquely suited to applications where these features are needed. The wheel is designed with a unique resin system that helps minimize smearing and reduces heat build-up. The open-web construction of the wheel ensures that it runs cool and resists loading, reducing the risk of part discoloration and warping while extending the life of the wheel. The EX2 Deburring Wheel is available in fine and medium grade abrasives.

The EX2 Deburring Wheel is available with either silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. Aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. While silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

Scotch-Brite™ industrial abrasives are unique surface conditioning products that incorporate abrasives into non-woven nylon or synthetic fibers. This combination creates an abrasive system that delivers consistent results for the life of the product. The open-web material used in the EX2 Deburring Wheel runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.