| SKU | 7010365820 |

|---|---|

| Legacy SKU | 61500065257 |

| UPC | 00048011143507 |

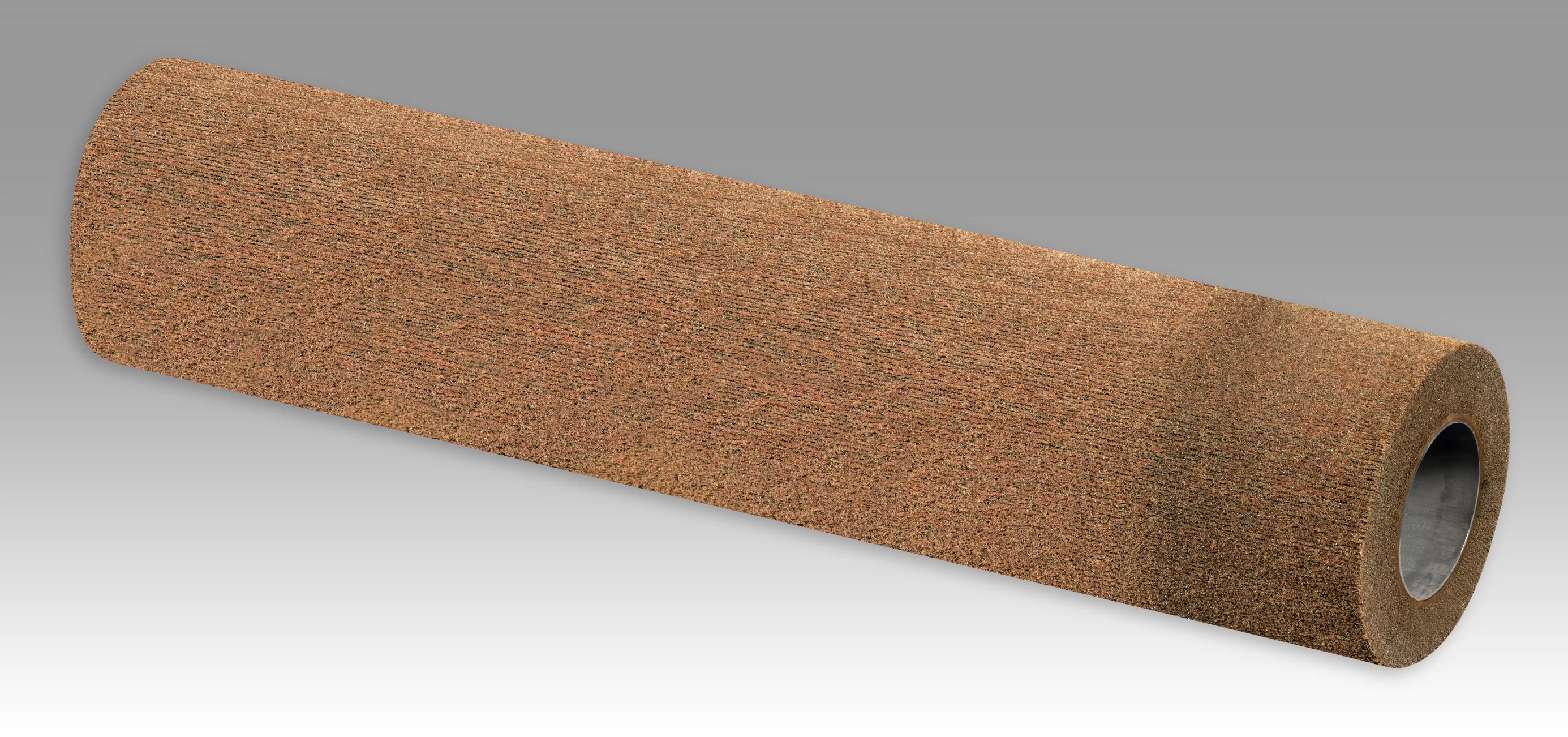

Scotch-Brite Flat Part Deburring Bonded Brush is a convolute brush designed for light-duty deburring applications. It's commonly used on stamped or laser cut parts, because its brush construction enables the abrasive to gently graze the tops of these surfaces without significantly gouging the surface or altering part geometry.

- Spring-like action of nylon fibers helps the brush make consistent contact with the workpiece, including contours, for more consistent results

- Gaps in open web permit debris to escape, helping to minimize loading

- By providing more complete removal of oils, light coatings and other contaminants, this brush helps reduce the need for separate cleaning steps

- Aluminum oxide and talc cut sharp without gouging, resulting in minimal material removal

- Ideal for use on coil stock, sheet stock and flat parts

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 3 in | 76.2 mm |

Shipping Dimensions |

|

| Weight | 19.99813 lb |

|---|---|

| Length | 37.9 in |

| Width | 7.8 in |

| Height | 7.8 in |

| Color | Tan |

|---|---|

| Maximum Speed | 4,000 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ Flat Part Deburring Bonded Brush used for?

The Scotch-Brite™ Flat Part Deburring Bonded Brush can be used for deburring and finishing flat surfaces on a variety of materials, including brass, copper, aluminum and stainless steel.

-

What’s special about the 7A Very Fine FP-CB type?

The 7A Very Fine FP-CB type of Scotch-Brite™ brush has tightly packed abrasive material that removes less material per pass, but provides great finish results and is ideal for producing decorative finishes.

-

How long does this bonded brush last in use?

. The lifespan of our products depends on usage; however, It offers consistent performance throughout its lifespan thanks to evenly distributed abrasives across the entire pad surface.

-

. Can I use it with water or oil while using on workpiece

You can use either water or mineral spirits when working with this product depending upon your job requirements without deteriorating the product quality since it doesn't have any negative impact from both substances.

-

. Does this come as single piece only?

Yes, you can buy one case of 1 EA pack size which contains a single piece at once

The Scotch-Brite™ Flat Part Deburring Bonded Brush is a cylindrical brush made up of multiple discs that are bonded together. The core of the brush can be made of either steel or fiberglass. The fiberglass brushes have a diameter of 6" and a center hole of 3". The steel brushes, on the other hand, have a diameter of 12" and a center hole of 5.75". The construction of the bonded brush makes it ideal for cleaning applications such as deburring. The discs are compressed together on a core, and the outer diameters of the discs abrade the workpiece, providing a more aggressive cut, especially on edges and contours. This is different from a flap brush, which gently laps the surface, making it a better fit for finishing. As the brush wears, the density of the brush remains the same due to the disc-style construction.

Each disc that is adhered to the Scotch-Brite™ Flat Part Deburring Bonded Brush features nylon web and abrasive mineral. There are two types of minerals to choose from: aluminum oxide or talc. Aluminum oxide is a popular choice among industrial professionals because of its fast cut and long service life. It works well on many substrates, including ferrous and non-ferrous alloys. Talc, on the other hand, is one of the softest synthetic minerals. It is a good mineral to use for deburring or finishing when gouging or marring are primary concerns, as it will not aggressively scratch the substrate.

The Many Benefits of Scotch-Brite™ BrushesScotch-Brite™ Brushes are high-performance brushes that are versatile and help reduce the need for messy, technique-dependent buffing compounds. These precision-made brushes are long-lasting and provide improved consistency and greater control over a number of critical metal prep and finishing tasks, including cleaning, stripping, deburring, polishing, aesthetic finishing, and more. Scotch-Brite™ brushes are engineered using proprietary 3M non-woven materials technology and are available in a wide range of grades and brush constructions. This allows us to tailor brush performance to your specific application requirements, unlike "all-purpose" brushes that may compromise quality, consistency, or durability. Additionally, because they provide more contact with the workpiece than bristle-type brushes, Scotch-Brite brushes last longer and can be run faster, helping you achieve higher throughput.