| SKU | 7010365687 |

|---|---|

| Legacy SKU | 61500301405 |

| UPC | 00048011650951 |

| Product Number | DB-FB |

Scotch-Brite Deburr & Finish PRO Combi Flap Brush was engineered to meld two applications deburring and finishing thereby reducing processing steps and enhancing productivity and throughput. This multi-purpose flap brush removes stubborn burrs and achieves fine finishes simultaneously. When it comes to saving time, the Scotch-Brite Deburr & Finish PRO Combi Flap Brush is a smart choice.

- Designed to deburr and finish in one step, reducing the need for multiple processing steps, enhancing throughput and productivity

- Flap brushes make continuous contact with the workpiece, resulting in more consistent finishes

- Flap construction helps minimize risk for chatter or residual marks

- Open web responds to surface irregularities without compromising part geometry

- Fibers in the web continually break down with use to reveal fresh mineral resulting in long service life

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 3-1/2 in | 88.9 mm |

Shipping Dimensions |

|

| Weight | 1.197 lb |

|---|---|

| Length | 6.3748 in |

| Width | 6.3748 in |

| Height | 3.6878 in |

| Color | Gray |

|---|---|

| Maximum Speed | 3,500 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ Deburr & Finish PRO Combi Flap Brush used for?

The Scotch-Brite™ Deburr & Finish PRO Combi Flap Brush is designed to deburr and finish metal surfaces, as well as blend and polish welds.

-

What materials can the brush be used on?

This brush can be used on a wide variety of metals including stainless steel, brass, copper, titanium and aluminum.

-

Is this product easy to use?

Yes! With its high-quality design with combs that protect against damage during use. The unique flap design minimizes undercutting while still providing consistent finishes even when pressure is applied inconsistently or in different directions.

-

:How often do I need to replace this tool?

A:The frequency at which you should replace your combi flap brush depends on various factors such as usage time and surface applications regularly monitored are recommended when using our products ensuring optimal results.

-

Q: Can I purchase smaller/larger sizes of the deburring brush?

A :Yes! We offer different sizes depending upon specific business requirements across several different industries; we'll match whatever size fits best for your needs.

Scotch-Brite™ Deburr & Finish PRO Combi Flap Brush is a high-performance abrasive tool that combines the benefits of coated abrasives and open-web non-woven abrasives. This brush can cut and finish in one step, making it a popular choice in metal fabrication industries. It is suitable for use on a variety of metals and can blend surface defects and generate grained finishes after weld removal for stainless steel and aluminum fabrication.

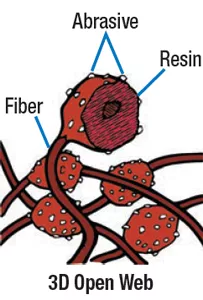

Form and FunctionThe Scotch-Brite™ Deburr & Finish PRO Combi Flap Brush has individual flaps made with nylon fibers and two different kinds of mineral: silicon carbide and proprietary 3M Precision Shaped Grain. The nylon fibers are interspersed with mineral, which is adhered to the fibers using resin. As the flaps abrade the workpiece, the fibers break down gradually, revealing sharp mineral for consistent cutting action. The open web is buoyant and spongy, allowing the flaps to respond to surface irregularities without compromising part geometry or dimensions.

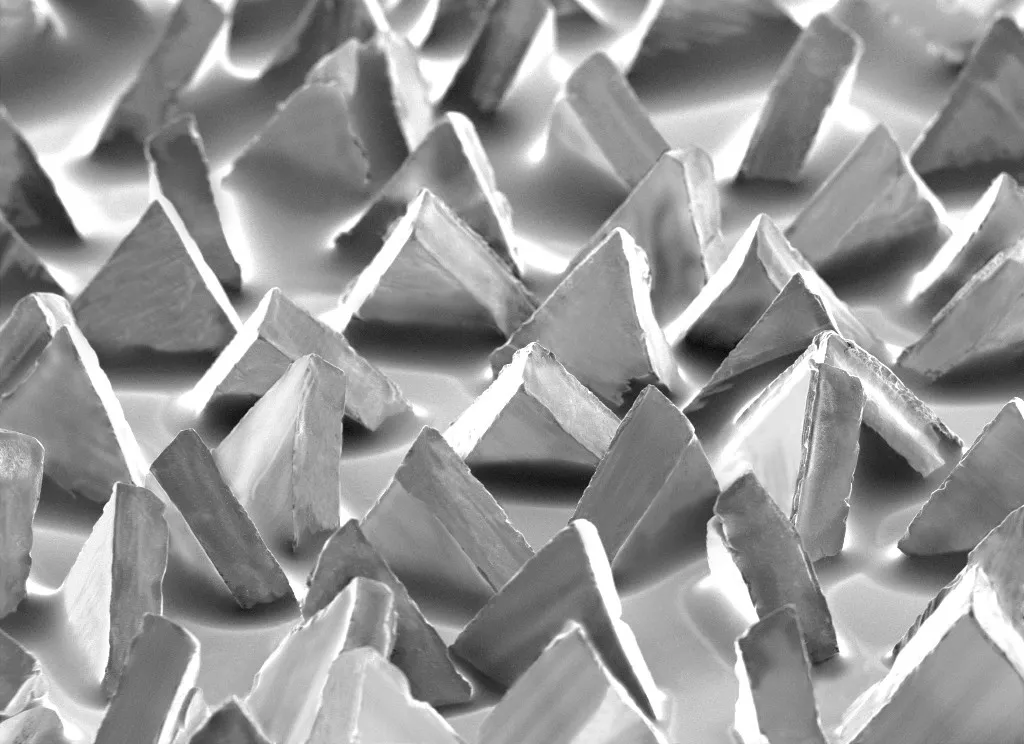

The Outstanding Performance of 3M Precision Shaped Grain3M Precision Shaped Grain (PSG) is a triangular shaped ceramic mineral grain produced using 3M technology. The razor-sharp corners of each triangle act like individual cutting tools that slice through metal, continuously shelf-sharpening as the points break off. This ensures extended high performance in heavy-duty production applications. The grains wear evenly and provide extra-long life and consistency with less grinding pressure. 3M PSG products outcut and outlast conventional ceramic industrial abrasive products, maximizing productivity and minimizing operator fatigue.

The Anatomy of a Flap BrushThe Scotch-Brite™ Deburr & Finish PRO Combi Flap Brush has individual flaps adhered to a fiberglass core. Under normal use, the brush minimizes chatter risk. As it spins, flaps rotate centrifugally and make continuous contact with the workpiece. By lapping the surface, flaps reduce the residual traces or marks that tend to be left by singular discs or discs ganged on a shaft. The brush may be used with a variety of tools, including backstand, match and finish sander, and inline sanders.

The Many Benefits of Scotch-Brite™ AbrasivesScotch-Brite™ industrial abrasives are unique due to their non-woven technology. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece. This reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite™ abrasives work fast and deliver consistent results, part after part. They may also enhance productivity while reducing the need for cleaning chemicals and wire brushes. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite™ abrasives are a versatile and reliable choice.