| SKU | 7010365374 |

|---|---|

| Legacy SKU | 61500193182 |

| UPC | 00048011338088 |

| Product Number | SL-DH |

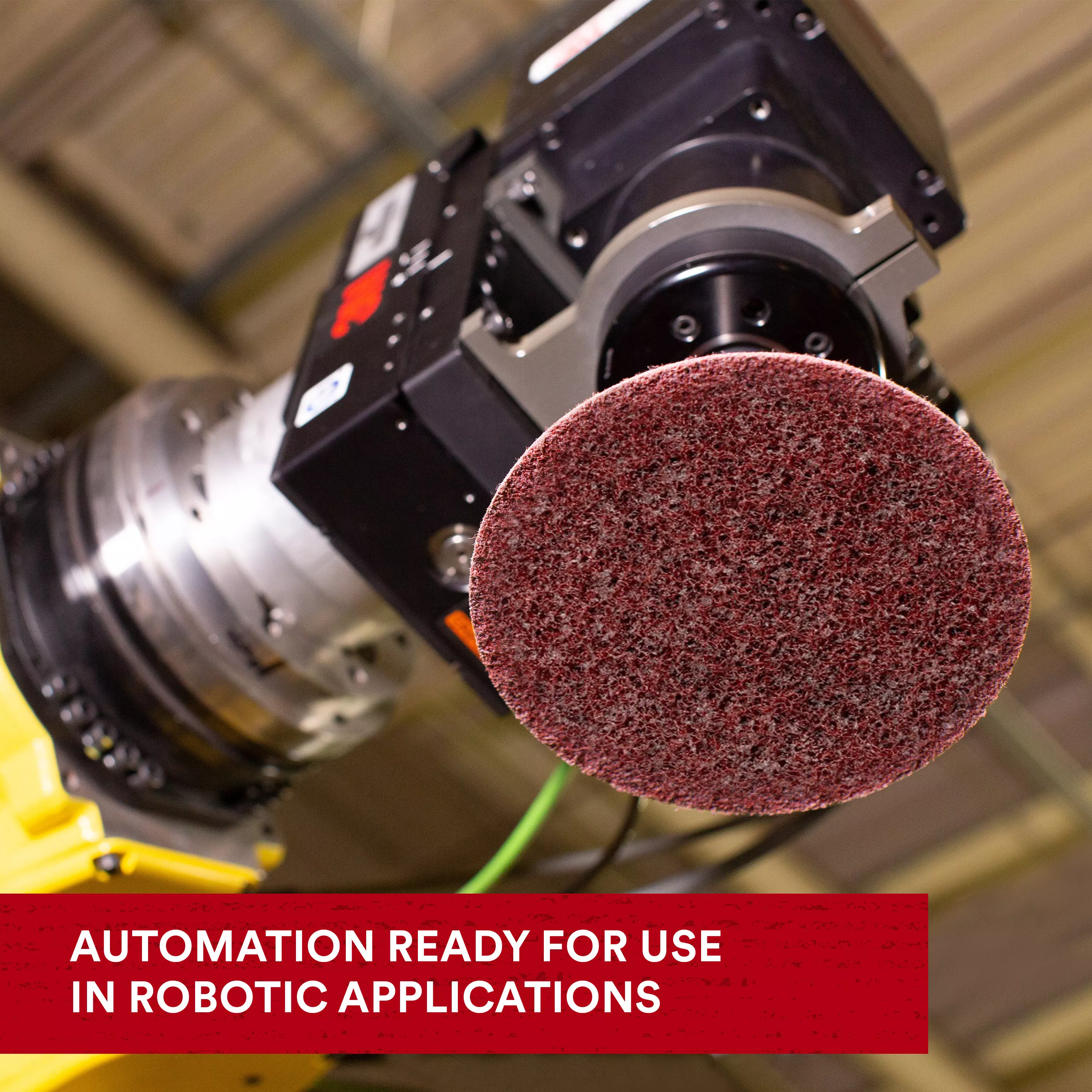

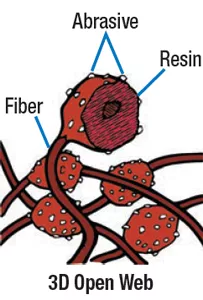

Scotch-Brite SL Surface Conditioning Disc is a durable product that combines blending and finishing capability with aggressive cut. The unique open web construction resists loading while giving you an aggressive cut and long product life on both edges and flat surfaces.

- VERSATILE WEB: Allows you to achieve your finish under a wide range of conditions

- EFFICIENT: Larger contact area allows for more coverage on irregular surfaces

- DURABLE: Medium duty construction to withstand a variety of tough jobs

- SECURE DISC REPLACEMENT: Hook and loop attachment system provides secure disc change outs

- RECOMMENDED APPLICATIONS: Blending, Refining, Deburring

- AVAILABLE IN A RANGE OF GRADES: Choose from Medium (MED), Coarse (CRS), Heavy-duty (CRS HD) and Super Duty (CRS SD) to fit your application needs

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 3.0997 lb |

|---|---|

| Length | 10.6 in |

| Width | 10.6 in |

| Height | 4.8 in |

| Color | Light Brown |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 13,000 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ SL Surface Conditioning Disc, and how does it differ from other abrasives?

The Scotch-Brite™ SL Surface Conditioning Disc is a non-woven abrasive made of nylon fibers that are impregnated with an aluminum oxide mineral. It differs from traditional coated abrasives because it provides consistent cutting throughout its entire life and doesn't leave fine metal particles which makes clean-up easy.

-

Can I use the Scotch-Brite™ SL Surface Conditioning Disc on stainless steel surfaces?

Yes! The Scotch-Brite™ SL Surface Conditioning Disc is specifically designed for use on a wide variety of metals, including stainless steel. Plus, the disc resists loading up and glazing over time, ensuring excellent performance.

-

How long do these discs typically last?

That will depend on various factors like how much pressure you apply to the disk when in contact with your working surface or if there is excessive heat build-up due to friction etc., but generally speaking customers can expect decent usage out of each disk before requiring a replacement.

To enhance productivity and reduce rework for any project, use the open web abrasive on both hard and soft metals, including stainless and carbon steels. This will contour and remove unwanted burrs, soils, and contaminants while maintaining the integrity of the project.

The hook and loop attachment system is designed for secure disc attachment, removal, and re-attachment. This system prevents contamination and the abrasive from gouging the workpiece when blending or refining.

With the 3M™ Scotch-Brite™ SL Surface Conditioning Disc, expect a great aesthetic finish on a variety of metals.