| SKU | 7010364339 |

|---|---|

| Legacy SKU | 61500040276 |

| UPC | 00048011089997 |

| Product Number | XL-WL |

Scotch-Brite EXL Deburring Wheel features a hard, dense consistency that quickly deburrs, finishes, and polishes all types of metals, composites, glass and leaves a smooth, clean surface. Its conformable characteristic makes the wheel ideal for deburring stamped or laser cut parts, or for finishing after belt sanding.

- EXCELLENT CHOICE FOR DEBURRING AND POLISHING: Produces a professional finish the first time — without undercutting, gouging, or distorting the workpiece

- UNIQUE RESIN SYSTEM: Made to help minimize smearing, reducing time spent cleaning surfaces

- CONFORMABLE NONWOVEN WEB: Scotch-Brite™ nonwoven synthetic fiber and abrasive mineral forms a web that is open, tough, conformable, and long-lasting

- CENTER HOLE ATTACHMENT: Utilize flanging or adaptors to adjust the center hole to a smaller size that fit your needs

- FAST AND EFFICIENT PERFORMANCE: Helps to reduce the risk of discoloration and warping, making it effective for all types of metals, composites, and glass

- CHOOSE YOUR MINERAL: Available either powered by super-sharp silicon carbide that excels in low-pressure and fine finishing applications or made from harder and more durable aluminum oxide

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 14 in | 355.6 mm |

| Center Hole Diameter | 8 in | 203.2 mm |

Shipping Dimensions |

|

| Weight | 12.5443 lb |

|---|---|

| Length | 14.6063 in |

| Width | 14.48819 in |

| Height | 5 in |

| Color | Gray |

|---|---|

| Maximum Speed | 2,550 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ EXL Deburring Wheel used for?

The Scotch-Brite™ EXL Deburring Wheel is designed to remove sharp edges and burrs from metal surfaces while providing a smooth finish.

-

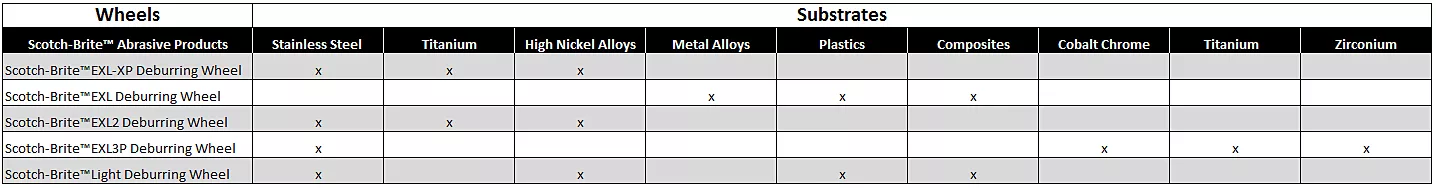

What type of surface can I use this deburring wheel on?

This deburring wheel can be used on a variety of hard metals, including stainless steel, brass, aluminum, and cast iron.

-

How long will one deburring wheel last before needing to replace it?

The lifespan of the deburring wheel depends on several factors such as the intensity of usage and size. However, if you store them well when not in use they are durable enough to last after several uses. It generally lasts longer than conventional wire brushes so with the proper handling and storage process it could be used up multiple times without losing its quality performance.

Runs Cool, Minimizes Smearing

The Scotch-Brite™ EXL Deburring Wheel is designed to create a clean surface without smearing, reducing the need for additional clean up and preparation. The wheel's convolute construction and clean, uniform wear keep it running smoothly and help the operator attain a professional finish while minimizing the pressure required on the workpiece. The nonwoven material of the Scotch-Brite™ runs cool and provides the EXL Deburring Wheel with uniform wear, keeping fresh abrasives continuously exposed, making it a superior choice on heat-sensitive substrates. The toughness of the wheel extends its service life.

Ideal for Robotic Deburring

Scotch-Brite™ industrial abrasives are a great option for robotic deburring, with a wide range of conformability options and high consistency. The Scotch-Brite™ EXL Deburring Wheel quickly removes burrs and sharp edges in end-of-arm tooling operations, delivering consistent performance through the full life of the abrasive.

Available in Your Choice of Mineral

The Scotch-Brite™ EXL Deburring Wheel is available with silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. Aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. While silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

The Many Benefits of Open Web Abrasives

Scotch-Brite™ offers a unique surface conditioning product with abrasives incorporated into nonwoven nylon fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results for the life of the product. The open-web material is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the nylon fibers.