| SKU | 7010362113 |

|---|---|

| Legacy SKU | 60440216053 |

| UPC | 00051115285936 |

| Product Number | 364UZ |

3M Paper Belt 346UZ is constructed with a premium aluminum oxide mineral. It is an open coat construction for loading resistance and is coated on an F-weight paper backing to efficiently sand and finish. F-weight is one of the heaviest, most rigid paper backings available and will achieve finer finishes than cloth backed belts in the same grade.

- F-weight heavy paper backing provides durability and smooth operation in either direction

- Anti-static treatment helps manage dust and loading

- Sine wave splice prevents hinging in splice area, resists fatigue, and minimizes chatter marks

- Premium aluminum oxide mineral provides aggressive cut and long abrasive life

- Open coat provides fast stock removal

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 16.89843 lb |

|---|---|

| Length | 55.31299 in |

| Width | 11.8748 in |

| Height | 8.3748 in |

| Color | Maroon |

|---|

PRODUCT FAQ

-

What is the size of the 3M™ Paper Belt 364UZ, and how many sheets does it come with?

The 3M™ Paper Belt 364UZ has a size of 52 in x 75 in, and comes with a total of five sheets per case.

-

What is the weight or grit level for this paper belt?

The P180 F-weight designation means that this paper belt has an abrasive grit equivalent to approximately between medium and fine sandpaper. This makes it ideal for grinding applications where finer finishes are necessary.

-

Is the Full-Flex capability only useful for specific types of equipment or tools?

No, as one of our newest innovations, Full-Flex technology on these belts allows them to easily conform to unusual shapes while still providing consistent pressure across their entire surface area. This means you can use them on most standard machines without having issues with slippage or poor rate-of-removal performance.

3M™ Paper Belt 346UZ provides a smooth operation and durability with its paper backing. The abrasive side has an open coat structure that resists loading better than closed coat belts, especially on soft wood. This belt also features 3M dust management technology that reduces static cling in the dust particles, allowing them to be evacuated more easily when coupled with an efficient dust collection system. The belt ends are joined using a sine wave splice that promotes belt strength and resists hinging and splice fatigue, which supports desired finishing results. The splice travels smoothly over contact wheels and platens, minimizes chatter marks, and promotes smooth operation in either direction for consistent finishing results.

3M™ Paper Belt 346UZ features a premium aluminum oxide abrasive, which is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Aluminum oxide mineral is widely used for sanding and finishing applications due to its high cut-rate, hardness, strength, and low heat retention. It is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

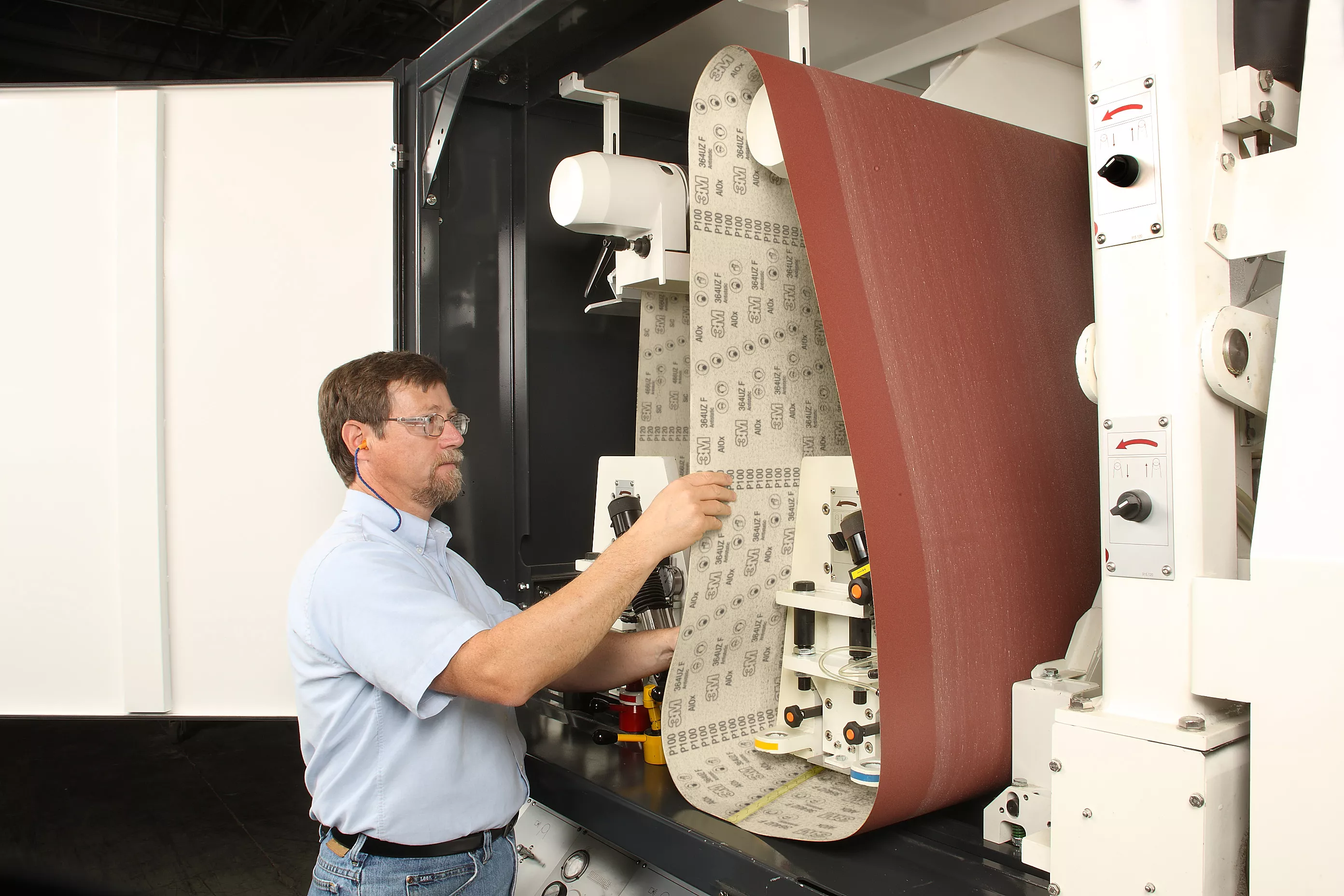

Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanders for many different applications on both wood and metal. 3M offers a broad selection of belts to fit most any industrial belt sander. Wider belts are used to dimension and sand large wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge or portable belt sanders for sanding or blending wood pieces such as cabinet doors.