| SKU | 7010361204 |

|---|---|

| Legacy SKU | 60440146862 |

| UPC | 00051115270864 |

| Product Number | 953FA |

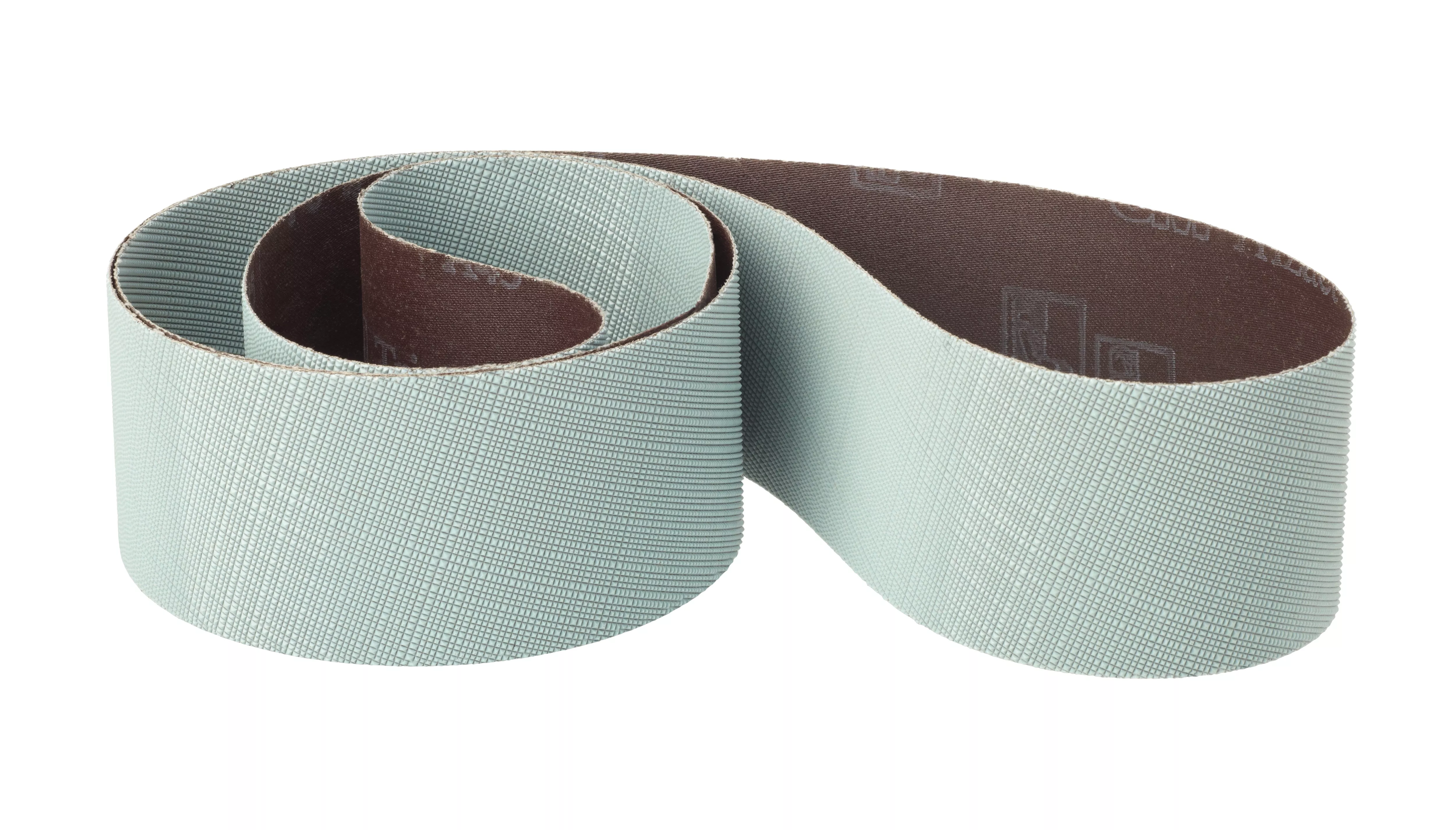

3M Trizact Cloth 953FA is constructed with a 3M proprietary ceramic grain for fast, aggressive cutting action. An XF-weight cloth backing is durable with additional flexibility. It is ideal for dimensioning and blending in wet centerless or flat grinding applications on ferrous, stainless steel and nonferrous workpieces.

- Use in wet centerless or flat grinding and finishing operations

- Consistent, predictable results for accurate part geometry and finish

- Fast cutting grain allows higher throughput, fewer belts

- Less dependent on operator skill to achieve close tolerances and finish specs

- Alternative to bonded wheels

- No need to invest in new machines or shifts with belts rather than bonded wheels

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 11.15 lb |

|---|---|

| Length | 14.08976 in |

| Width | 14.00984 in |

| Height | 9.2 in |

PRODUCT FAQ

-

What is the 3M™ Trizact™ Cloth Belt 953FA used for?

The 3M™ Trizact™ Cloth Belt 953FA is ideal for applications that require consistent and precise finish removal.

-

How coarse is the A6 grade of this belt?

The A6 XF-weight rating means that this belt has an aggressive, coarse abrasive designed to remove tough marks and imperfections from surfaces.

-

What size are these belts, and how many come in a case?

These Film-lok belts measure 4 inches wide by 84 inches long, with each case containing twenty individual belts ready to use.

-

Can I trust the build quality - will these belts last a reasonable amount of time before needing replacement?

: Absolutely! As part of our standard manufacturing process at 3M, we prioritize high quality materials and production techniques. This ensures that our products like the Trizact Cloth Belt have excellent durability so they can provide consistent performance over time on tough applications.

With the 3M™ Trizact™ Cloth Belt 953FA, you can consistently achieve accurate part geometry with ease, speed, and consistency. This belt is versatile and available in grades from A300 for stock removal to A6 for final finishing and polishing. It is also available in converted forms up to 25 inches wide.

Grades A10 and A6 employ an engineered aluminum oxide mineral, while A300 is available on a stiffer YF-weight backing. 3M designed an abrasive mineral to deliver Trizact™ consistency with the cutting action of ceramic abrasive grain. This new shape, packed with durable ceramic grain, introduces a full line of consistent Trizact belt products for stock removal through final finishing in wet applications on stainless, mild, and hardened steel.

The ceramic grain is a chemically engineered ceramic aluminum oxide mineral that has a unique "stay sharp" crystalline structure. This grain as it wears continually reveals fresh cutting edges, ensuring a sustained cut and longer product life. This durable, cost-effective abrasive solution delivers real productivity benefits across an operation without the premature dulling associated with traditional abrasives.

Fast cutting action allows high throughput and/or fewer belts on multiple-head machines, which means you operate at significantly lower total cost. 3M abrasive belts perform more reliably independently of operator variables and you can run them without investing in new machines or shifts.

Alternative to Bonded WheelsLess technique-dependent tools help to deliver a more consistent result. Bonded wheels generally depend upon the dexterity, hours of experience, and machine knowledge of the operator to achieve consistently exceptional results.

Mill Rolls, Z-Mill Rolls, Hard Chrome Rolls and Thermal Sprayed RollsAccomplish typical work roll refinishing with a sequence of 3M™ Trizact™ Belts. The first step uses 3M™ Trizact™ Cloth 953FA A300 belt to remove 0.005 to 0.015 inches of material from the roll diameter. Refine the finish quickly by replacing the roughing belt with a sequence of finer grade 953FA belts, depending on finish requirements. Mirror finishes (<1 Μ in. Ra) have been achieved.