| SKU | 7010360128 |

|---|---|

| Legacy SKU | 60440154759 |

| UPC | 00051115278754 |

| Product Number | 217EA |

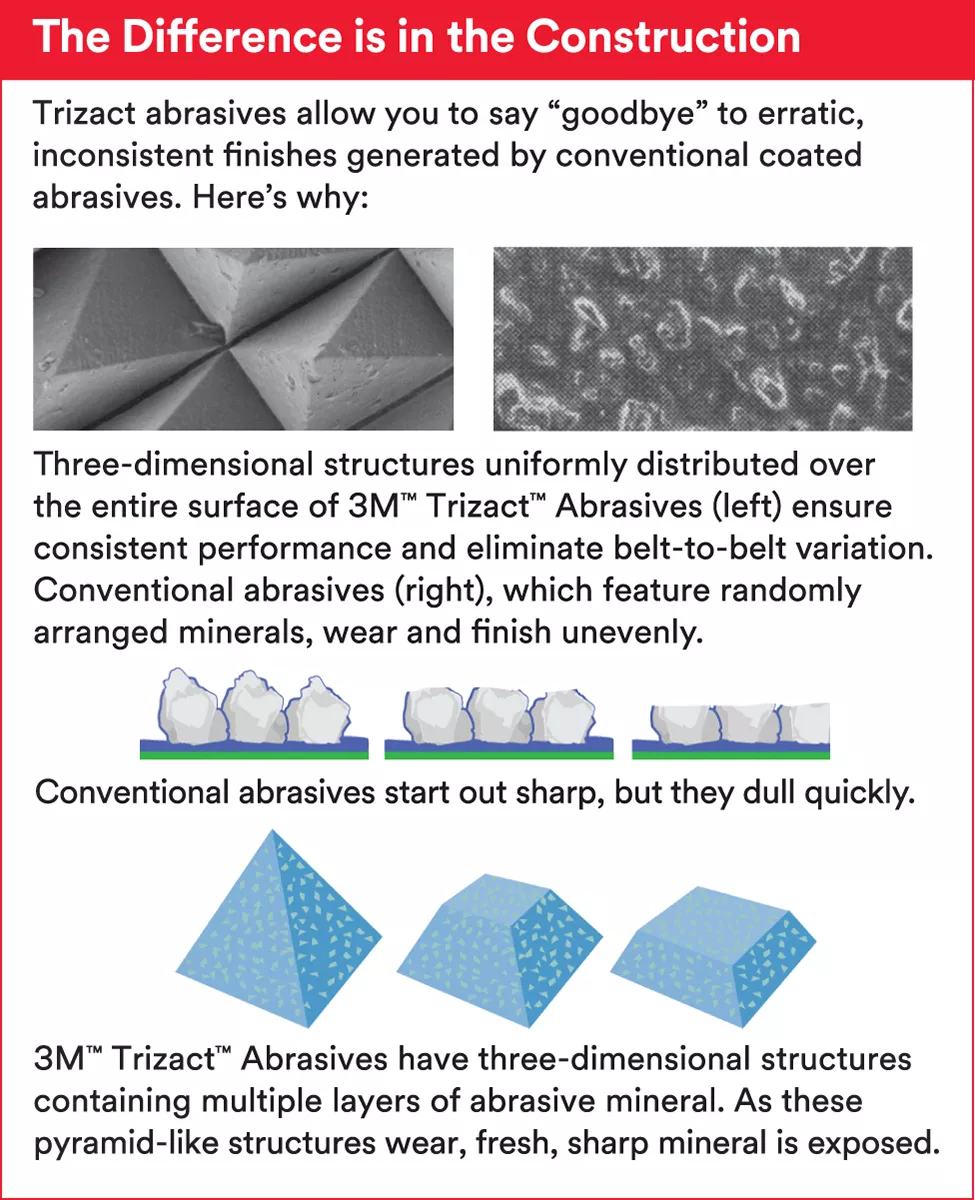

3M Trizact Cloth Belt 217EA uses proprietary microreplication technology in which micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on a JE-weight rayon backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.

- Microreplicated pyramids wear away to continually expose fresh mineral for a consistent cut throughout the life of the belt

- Flexible JE-weight cotton cloth backing flows over contoured surfaces for consistent finishing

- Consistency and long abrasive life make this belt great for use in robotic applications

- For intermediate finishing and fine polishing prior to plating or buffing

- Ideal for light pressure applications, allows abrasive to break down and maintain cut and produce consistent finishes

- Produces finer finishes than conventional coated abrasives

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 4.108 lb |

|---|---|

| Length | 12 in |

| Width | 12 in |

| Height | 4.81299 in |

| Color | Tan |

|---|

PRODUCT FAQ

-

What is the Trizact™ Cloth Belt 217EA made of?

The Trizact™ Cloth Belt 217EA, A45 JE-weight, is made up of high-quality aluminum oxide and abrasive minerals bound to a cloth backing for efficient abrasive cutting power.

-

How many belts come in a case?

There are 50 belts included per case of this product.

-

What size is the 3M™ Trizact™ Cloth Belt 217EA?

The belt dimensions are approximately 3-1/2 inches by15-1/2 inches making it perfect for most motor-powered machines used on metals.

-

Is there any other option regarding flexibility in these belts?

Yes! Full-flex film-lok technology adds improved conformability to aerodynamic shapes such as blades or vanes with small radii.

-

Is this belt suitable for polishing?

The Trizact™ Cloth Belt software application encourages users to blend and clean stains without creating excessive surface roughness, so it can be ideal for finishing processes. However, it is unlikely that you will obtain polished surfaces with this particular model Considering its low grit number (45)

The 3M™ Trizact™ Cloth Belt 217EA is designed to provide consistent finishes on hard metals such as carbon and stainless steel. The abrasive and resin structure is formulated to break down under medium pressure, keeping fresh, sharp mineral cutting. Additionally, this belt features a grinding aid that helps prevent heat buildup, warping, and discoloration. The JE-weight, durable cloth backing provides control, conformability, and effective medium-pressure grinding. The resin bonded abrasive provides heat resistance and helps prevent delamination.

Ideal for Robotic Finishing and PolishingRobotic metal polishing requires a consistent, refined cut and long abrasive life. 3M™ Trizact™ abrasives can deliver near-mirror finishes while also providing the abrasive life that helps reduce changeouts and downtime in robotic cells. This maximizes the efficiency of the cell, allowing you to produce more parts per belt.

Runs Smooth, Finishes ConsistentlyThe film media splice minimizes "chatter marks" and ensures smooth running and consistent results. Proprietary Trizact™ abrasives produce a finer finish, achieve results faster, and last longer when compared to conventional abrasive products.