| SKU | 7010360111 |

|---|---|

| Legacy SKU | 60440141517 |

| UPC | 00051111693285 |

| Product Number | 472L |

3M Microfinishing Film Belt 472L was designed for superfinishing and powertrain microfinishing. This belt helps achieve uniform, consistent finishes on parts where close tolerances are important.

- Micron-graded silicon carbide mineral cuts sharp and fast while producing extremely consistent, fine finishes

- High-strength 5 mil polyester backing won’t yield or deflect when run, contributing to aggressive cut

- May be used on metal, plastic, wood and various other substrates

- Open coat construction reduces loading to maintain consistent, sharp cut and extend disc life for greater productivity

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 11.99976 lb |

|---|---|

| Length | 12 in |

| Width | 12 in |

| Height | 4.81299 in |

| Color | Gray |

|---|

PRODUCT FAQ

-

What is the 3M™ Microfinishing Film Belt 472L primarily used for?

The 3M™ Microfinishing Film Belt 472L is typically used for precision finishing, including micro-finishing and super-finishing operations on hard or soft materials.

-

How durable are these belts? Will they last a long time?

These belts are made with a polyester film backing that offers excellent flexibility, durability, and resistance to water. When used properly, they can provide consistent results over a long period of time.

-

Can this belt be used with wet or dry applications?

Yes! This belt is designed to work well with both wet and dry applications.

-

Are there any safety precautions I should take when using these belts?

As with any abrasive product, it's important to wear proper personal protective equipment (PPE), such as safety glasses and gloves. Also be sure to follow all recommended operating procedures provided by the tool manufacturer in order to reduce risk of injury.

The 3M™ Microfinishing Film Belt 472L is designed to deliver uniform, consistent finishes on parts where a close tolerance finish is essential. Micron-graded silicon carbide mineral is ideal for finishing of metals, plastics, wood and various other substrates.

Consistent and predictable finishes are key for flat parts like die castings, and cylindrical or contoured workpieces such as auto parts. 3M™ Microfinishing Film Belt 472L helps produce fine finishes and achieve close tolerances by way of a durable, uniform film backing and micron-graded mineral. Recommended applications are finishing on metals, plastic, wood and various other substrates.

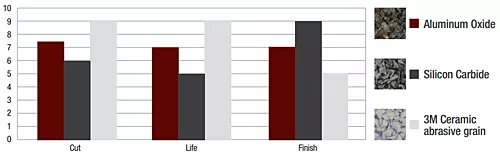

Silicon Carbide Mineral and Polyester Backing3M™ Microfinishing Film Belt 472L is made by adhering micron-graded silicon carbide mineral to polyester film using a resin bond. Silicon carbide mineral is very hard and fractures easily, resulting in freshly exposed sharp edges that cut fast and produce a bright looking finish. While it wears faster than aluminum oxide, it produces a brighter finish. Belt 472L is available in a variety of grades, so operators can tailor the grade to their part.

The high-strength 5 mil polyester backing won't yield or deflect when run, which is helpful when close tolerances are important. With a uniform backing, the abrasive maintains consistent contact with the workpiece to maintain critical geometries.

Get Close to the Close ToleranceAcross industries, from transportation to heavy equipment, from general industrial to aerospace, professionals value part integrity and consistency. Combining the strength of a polyester film backing with the aggressive cutting qualities of micron-graded silicon carbide, 3M™ Microfinishing Film Belt 472L is a good match for workpieces that require precise and uniform cutting action.