| SKU | 7010330625 |

|---|---|

| Legacy SKU | 66000007154 |

| UPC | 00051115331145 |

| Product Number | 840399 |

The Standard Abrasives Quick Change Cleaning Pro Disc is ideal for cleaning welds, removing corrosion, rust, scale, paints, varnishes and sealants from difficult to reach surfaces. Constructed of large nylon filament, they are an open, non-loading structure that performs rapid removal of surface contaminants, while producing fine finishes.

- Can be used for cleaning, finishing and blending on fiberglass or metals

- Open abrasive design resists loading for faster cut rates

- Nylon mesh and silicon carbide combination offers a fine cleaning finish

- Available with either the Quick Change TS or TR attachment systems

- Provides consistent finish on flat and irregular surfaces

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2 in | 50.8 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 6.061 lb |

|---|---|

| Length | 23.6878 in |

| Width | 9.75 in |

| Height | 7.9378 in |

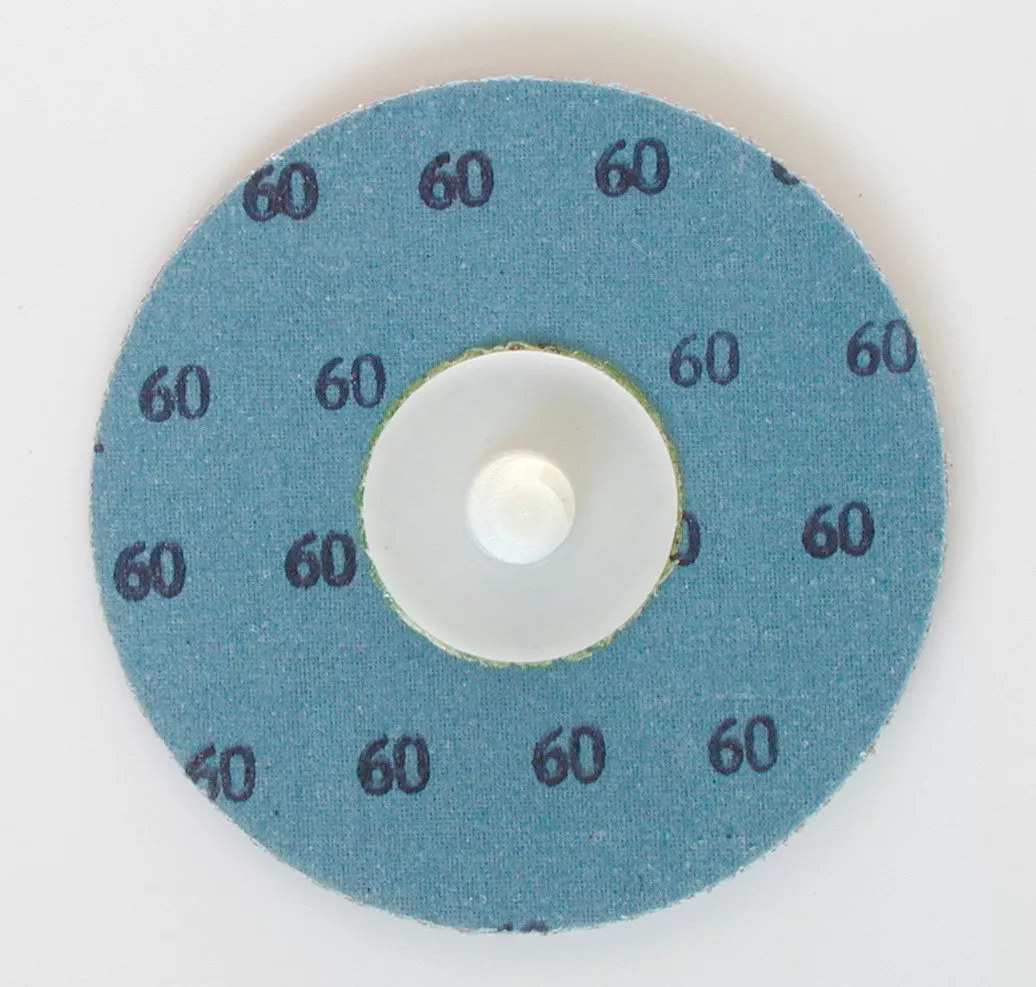

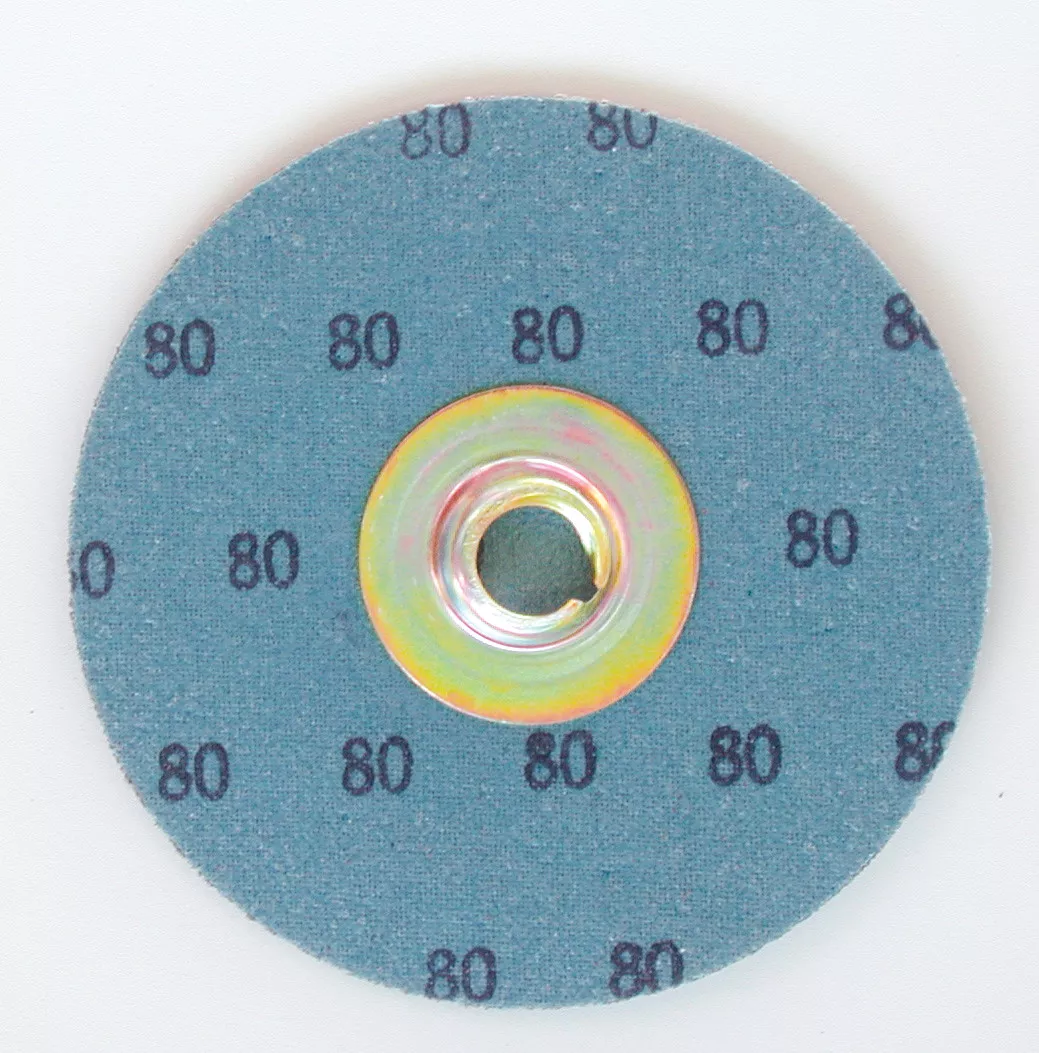

| Color | Blue |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the Quick Change Cleaning Pro Disc made of?

The Quick Change Cleaning Pro Disc 840399 is made of silicon carbide abrasive and a durable plastic backing.

-

Can I use this disc on my drill or angle grinder?

No, you cannot. This product works exclusively with the Standard Abrasives™ Quick Change System which requires a die grinder or other tools that accept 2 inch quick change discs.

-

How many discs are included in one case of this product?

There are 250 pieces per case for this particular SKU. They come packaged as 25 units (one inner pack) by 10 inner packs (250 total).

This Standard Abrasives™ Quick Change Cleaning Pro Disc is lined with silicon carbide, which is a popular choice among industrial professionals because of its fast cut-rate and smooth finish. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep. While it breaks down faster than aluminum oxide, it produces a finer finish. This makes the Standard Abrasives™ Quick Change Cleaning Pro Disc best suited for sanding and finishing applications on fiberglass, composite or soft metals.

Open Coat ConstructionSanding sheets cut better and last longer when dust isn't clogging the cutting surface of the abrasives. Open coat construction means the abrasive grains are placed with space between them to help evacuate sanding debris and avoid clogging of the cutting edge of the grains. Additionally, the open coat feature provides a more aggressive cut than a comparable closed coat abrasive of the same grade. All of this adds up to increased productivity and reduced material consumption.

The Quick Release System3M™ TS and TR quick change discs are smaller discs that have a plastic threaded button or screw designed to easily and quickly screw onto a quick change enabled tool so that you can conveniently change discs with a simple twist-off, twist-on motion. These systems provide a secure attachment even for heavy-duty applications, and the variety of available discs allows swapping from one application to the next in seconds. Each TS and TR attachment is also color-coded to identify its grade, making it easy to grab the grade required for different applications.

Quality Standard Abrasives™ Solutions for Industrial ApplicationsThe Standard Abrasives brand has supplied quality abrasives to the metalworking industry for over 50 years. Customers rely on our broad offering of high performance products including coated, bonded, and non-woven abrasive lines.