| SKU | 7010329147 |

|---|---|

| Legacy SKU | 61500188695 |

| UPC | 00048011278704 |

| Product Number | HS-FB |

The Scotch-Brite High Strength Flap Brush is uniquely designed for lighter duty and specialty applications, such as cleaning and finishing.

- Aluminum Oxide mineral cuts sharp but leaves a soft scratch pattern, good for cleaning and finishing

- Available in a range of grades, densities and sizes so operators can tailor the brush to meet the needs of their unique application

- Especially dense web contributes to abrasive longevity and durability

- Open web is buoyant and responsive, minimizing alteration of the workpiece

- Open web has gaps between fibers, helping reduce loading and clogging of fibers

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 12 in | 304.8 mm |

Shipping Dimensions |

|

| Weight | 1.706 lb |

|---|---|

| Length | 12.4 in |

| Width | 12.4 in |

| Height | 2.6 in |

| Color | Maroon |

|---|---|

| Maximum Speed | 2,500 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ High Strength Flap Brush used for?

The Scotch-Brite™ High Strength Flap Brush is a versatile and flexible abrasive brush designed to deliver consistent, high-quality finishes on various metal surfaces. It's commonly used in industrial settings such as automotive manufacturing and repair.

-

How durable is this flap brush?

This flap brush has been designed with durability in mind. Made from tough nylon fibers, it can withstand heavy use without compromising its performance or quality of finish.

-

Can this flap brush be used wet or dry?

Yes! The Scotch-Brite™ High Strength Flap Brush can be utilized either wet or dry, depending on your needs and preferences. Its design makes it an excellent option for stock removal, blending welds, deburring edges, and surface preparation.

-

How long does this 3M product usually last?

All 3M products have been created with longevity in mind- the same applies to our High Strength Flap Brushes! Depending upon usage conditions such as grit aggressiveness or pressure applied during using them - they could last anywhere between several hours to weeks.. One thing we know for sure that you won’t need frequent replacement if used within their specifications and while taking proper care ( cleaning frequently etc...)

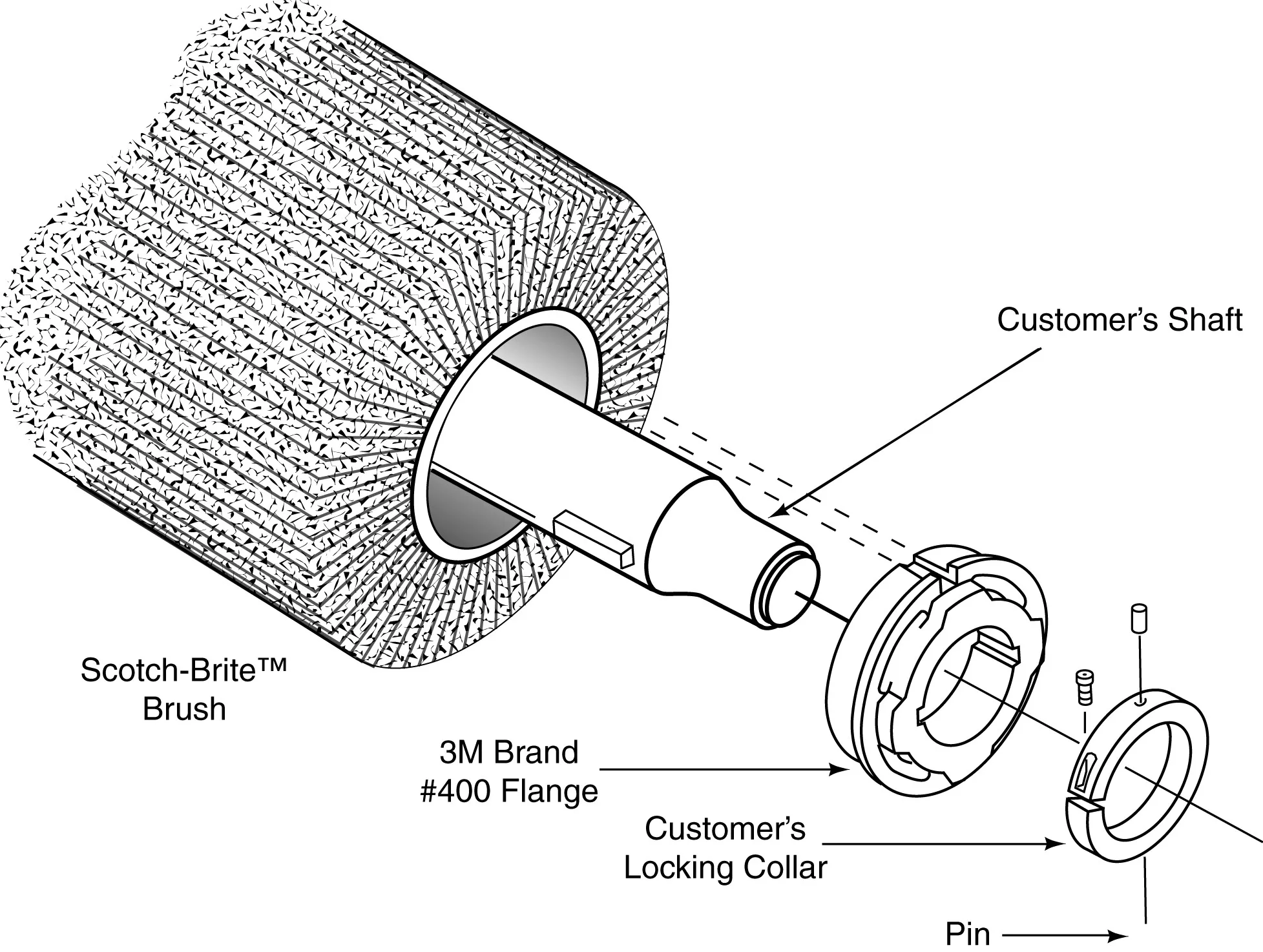

The Scotch-Brite™ High Strength Flap Brush is made by bonding sections of non-woven material, slit lengthwise, to a cylindrical fiberglass core. Compared to other Scotch-Brite™ Flap and Cleaning Brushes, the High Strength Flap Brush has a more durable open web and provides a low to medium aggressive cut.

When choosing the right abrasive for a workpiece, many factors come into play. The Scotch-Brite™ High Strength Flap Brush is ideal for medium-duty cleaning and finishing applications because it is long-lasting and can withstand repeated wear. It is not so aggressive that it will damage the workpiece, but the medium grade aluminum oxide mineral cuts softly and leaves a fine scratch pattern.

Flap brushes have a unique construction that minimizes the risk of chatter and marks. The flaps rotate centrifugally and make continuous contact with the workpiece, lapping the surface and eliminating residual traces or marks left by singular discs or discs ganged on a shaft. The brush can be used with a variety of tools, including a backstand, match and finish sander, and a centerless grinder.

Scotch-Brite™ abrasives offer consistency and responsiveness, and each brush offers unique capabilities based on different grade and density combinations. The High Strength Flap Brush is available in a range of grades, densities, and sizes, so operators can choose the right brush for their specific application.

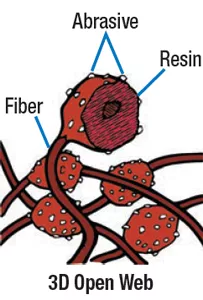

The Many Benefits of Open Web AbrasivesScotch-Brite™ industrial abrasives are unique due to their non-woven technology. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The fibers respond to contours and effectively remove unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, reducing rework and boosting productivity. Gaps in the web allow swarf to escape, preventing debris from clogging the mineral.

The fibers in the web continually break down with use, revealing fresh mineral for exceptional consistency, superior cut performance, and an extremely long service life. Scotch-Brite™ products not only enhance productivity but also increase operator safety by reducing the need for cleaning chemicals and pastes and replacing wire brushes that can break off and cause injury. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.