| SKU | 7010328647 |

|---|---|

| Legacy SKU | 60600140614 |

| UPC | 00051111688151 |

| Product Number | 305EA |

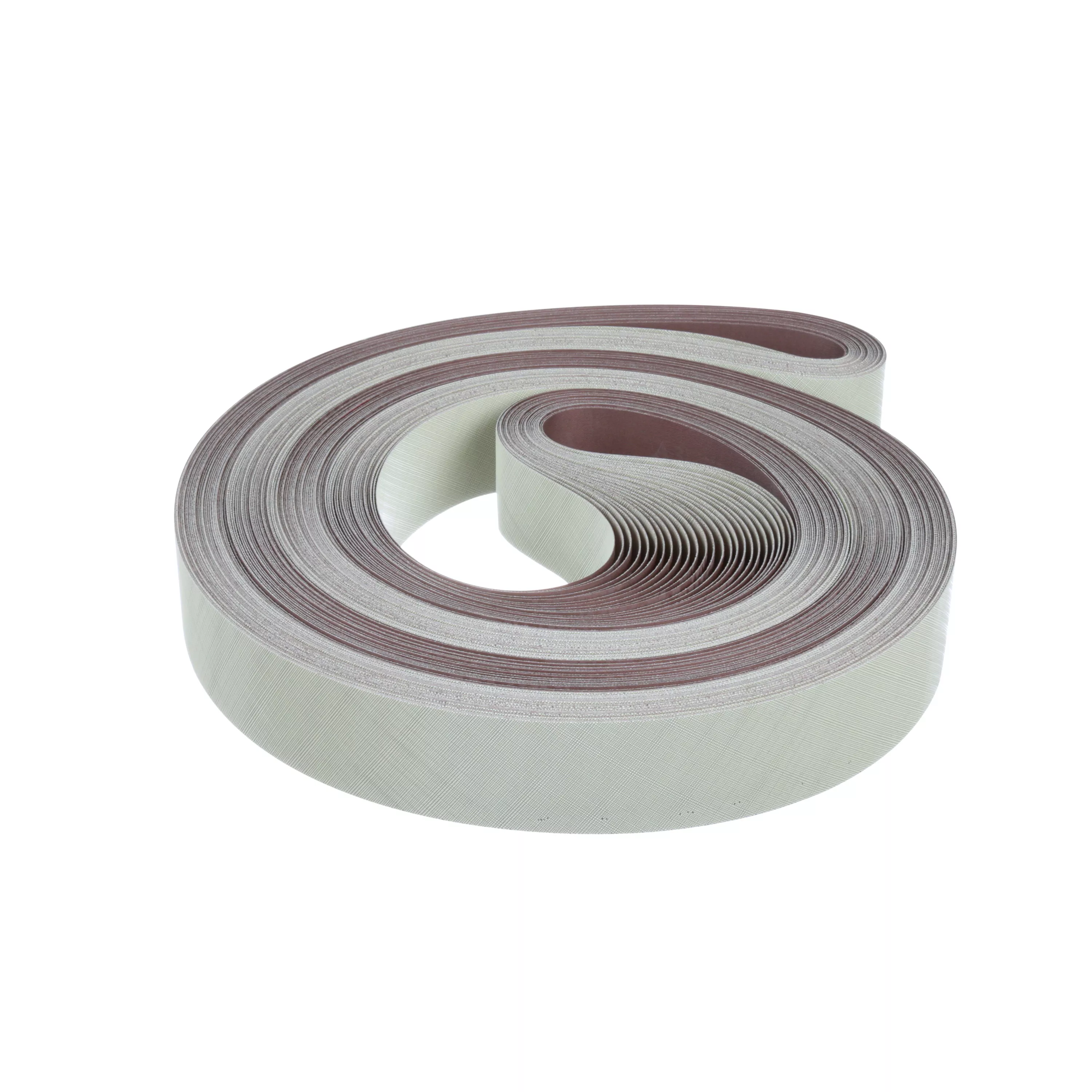

3M Trizact Cloth Belt 305EA features an aluminum oxide mineral constructed on a very flexible JE-weight backing. It is resin bonded for heat resistance and contains a grinding aid to assist in cutting and keeping the work piece cool. This belt offers outstanding consistency and long belt life in both robotic and offhand applications. It is available in micron grades A5 and A3.

- Excellent finish consistency from day one for final finish and pre-polish applications

- Aluminum oxide grain cuts fast, stays sharp

- Engineered for dry sanding applications, runs cooler

- Proprietary abrasive mineral runs with less pressure, cleaner, cooler and with fewer belt changes

- Fewer steps and fewer rejects means lower grinding cost per part

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 16.16429 lb |

|---|---|

| Length | 14 in |

| Width | 14 in |

| Height | 4.81299 in |

PRODUCT FAQ

-

What is the 3M™ Trizact™ Cloth Belt 305EA?

The 3M™ Trizact™ Cloth Belt 305EA is a type of industrial abrasive belt used for sanding, grinding, and finishing metal surfaces.

-

What size is the belt and how many come in a case?

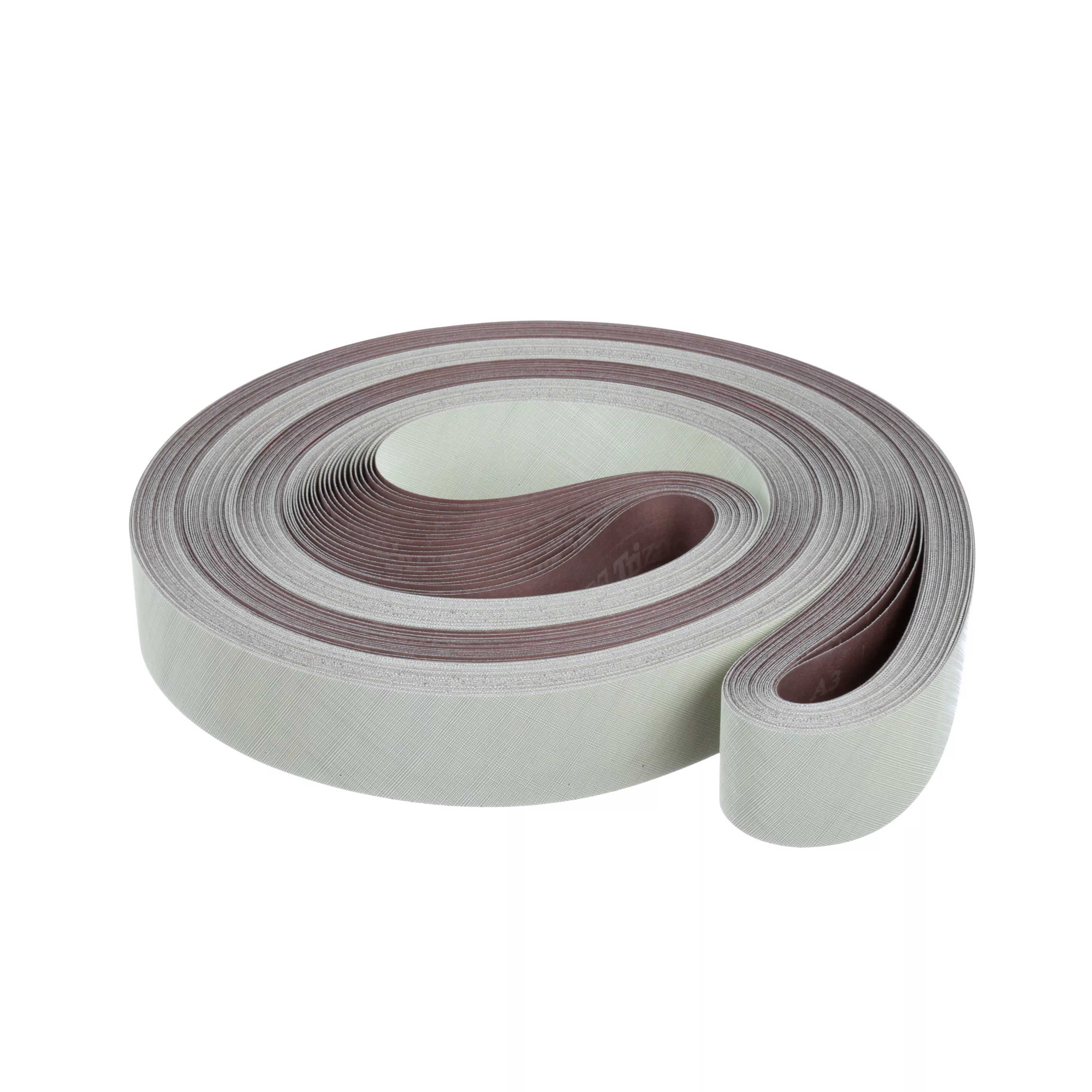

The belt measures 2 inches by 132 inches (5.08 cm x 335.28 cm) and comes with a full-flex design and Film-lok attachment system. It also features an A3 JE-weight backing. There are 50 belts in each case.

-

How long does this abrasive material last before needing replacement?

The life of the abrasive material largely depends upon your specific application needs such as desired finish quality, workpiece shape/size/material hardness, etc. However, these belts have been specifically designed to improve productivity while providing consistent finishes for years to come.

-

Can I use this product for wet or dry applications?

Yes! This versatile cloth belt can be used both dry or wet on various types of metals including stainless steel, carbon steel, aluminum etc., offering great flexibility during material processing.

-

Is there any possibility that your products contain potentially harmful substances like silica dust or heavy metals?

; Definitely not! At our company we thoroughly test all products through multiple stages~ production & distribution ~ ensuring their compliance with all mandatory safety regulations from local authorities around the world (e.g., OSHA). All materials employed throughout their supply chain adhere to stringent standards put forth through our self-imposed Environmental Health & Safety liability policy as well as REACH Regulations ensuring customers' ultimate peace-of-mind when using our abrasives products!

For fast, fine, consistent finishes, our 3M™ Trizact™ Cloth Belt 305EA is a go-to belt. Microreplicated Trizact abrasive grain is engineered to start sharp and stay sharp longer, delivering less variability than conventional abrasives throughout its life. 3M developed this enhanced product to address final finish and pre-polish applications where fine, precise finishes are needed.

This belt uses aluminum oxide, a high-purity, tough mineral primarily used for precision grinding of steels and hard alloys, on a very flexible JE-weight rayon cloth backing. A resin bond adds heat resistance and a grinding aid to keep the work piece cool for dry sanding applications. The belt is available in a variety of forms including narrow, file, portable pump sleeve, and wide and flat finishing belts.

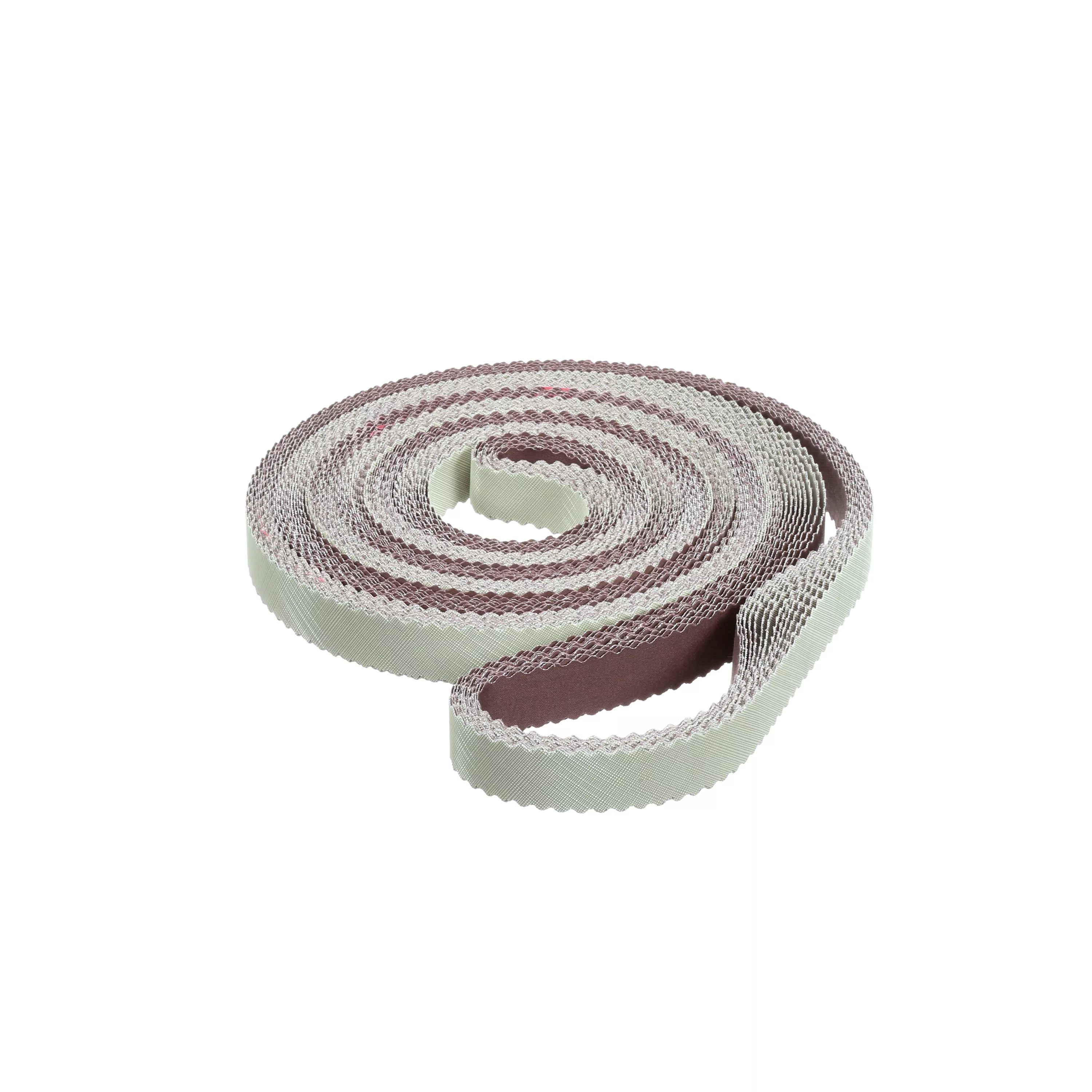

Science of Abrasion: Microreplicated Abrasive MineralDerived from patented 3M microreplication technology, Trizact abrasives consist of very small, precisely-shaped, three-dimensional structures distributed uniformly over the abrasive backing. Unlike conventional abrasives, which are constructed from randomly spaced and irregularly shaped minerals, the uniform configuration of Trizact abrasives helps deliver more consistent finishes with higher cut rates, and cooler grinding and finishing temperatures.

Recommended ApplicationsChoose 3M's Trizact Cloth Belt 305EA where fine, precise finishes are needed and for pre-polish and pre-plate finishing applications on stainless steel, cobalt chrome, titanium, and zirconium substrates, such as motorcycle parts, golf clubs, and sporting goods products. The belt works well for final steps in casting and forging, dimensioning, and scratch refinement in the manufacture of surgical and orthopedic devices.

The Trizact AdvantageThe finer finishes that 3M Trizact Cloth Belt 305EA achieves and reduced downstream polishing time, due to fewer steps and fewer rejects, equals greater productivity and lower grinding cost per part. 3M product innovation and technical expertise, combined with over a century of practical abrasives application experience, can help you meet today's demanding quality, cost, material, and turnaround challenges. See how more efficiency can save you money and protect your product quality — and how 3M products support a more consistent and predictable process from start to finish.