| SKU | 7010328592 |

|---|---|

| Legacy SKU | 60600131886 |

| UPC | 00051111678886 |

| Product Number | 777F |

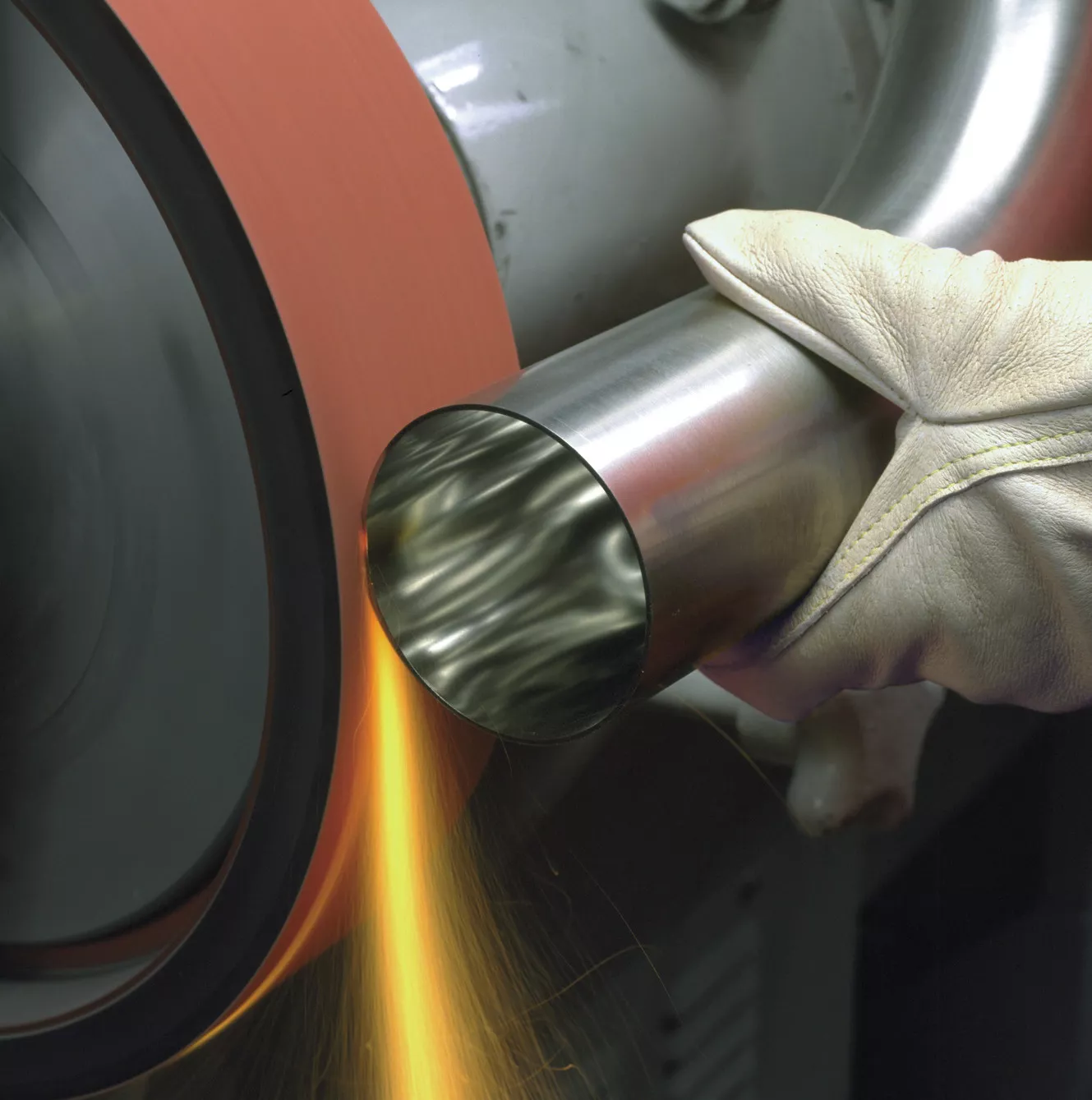

Take advantage of increased durability and cutting efficiency with 3M Cloth Belt 777F. This belt features a blend of 3M Ceramic Abrasive Grain and aluminum oxide that outperforms aluminum oxide belts in stock removal and metal finishing applications. The heavyweight cloth backing supports high-pressure applications, performs well on heat-sensitive metals, and can be used dry or with lubricant.

- Ceramic aluminum oxide grain blend cuts faster and lasts longer than traditional aluminum oxide

- Produces more parts per belt than traditional aluminum oxide belts, requiring fewer belt changes

- Heavyweight polyester backing supports high-pressure applications and can be run wet or dry

- Contains a grinding aid to reduce heat and increase performance when grinding stainless steel

- Durable resin bond resists heat deterioration, which extends the life of the belt

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 46.55299 lb |

|---|---|

| Length | 20.4 in |

| Width | 20.4 in |

| Height | 9.3 in |

| Color | Orange |

|---|

PRODUCT FAQ

-

What type of abrasive material is used in this cloth belt?

The 3M™ Cloth Belt 777F uses a blend of ceramic and aluminum oxide mineral to achieve efficient cutting and long life.

-

Can this belt be used for wet sanding?

Yes, the Film-lok backing on the 777F provides reduced loading during wet operations, allowing you to use it for both dry and wet sanding applications.

-

How flexible is the L-flex design of this belt?

The L-flex design allows for greater flexibility without sacrificing strength or durability. This makes it easier to use in contoured or curved areas like automotive body panels.

-

What applications is this product best suited for?

Our customers have had success with using the 3M™ Cloth Belt 777F across multiple industries such as woodworking, metalworking, paint prep and blending.

-

Is there any warranty that comes with the purchase of these belts?

We're confident you'll be satisfied with your purchase but should you encounter any issues our sales team will help process any warranty claims at no extra cost.

3M™ Cloth Belt 777F is a high-performance abrasive belt that is perfect for grinding, deburring, blending, and finishing stainless steel, nickel alloys, and cobalt alloys. This belt contains a grinding aid that reduces running temperatures when used on heat-sensitive alloys. The abrasive grain is bonded to the backing with resin to maintain durability under high heat and pressure.

Ceramic Abrasive Grain Boosts PerformanceFor increased performance, 777F products feature aluminum oxide blended with 3M ceramic abrasive grain for a harder, longer-lasting abrasive. The ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut-rate and durability, making the Cloth Belt 777F an excellent choice for moderate stock removal and surface preparation.

Sized to Suit Your NeedsThese abrasive belts are available in various widths and lengths for sanding both wood and metal. 3M offers a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough-cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

Find Your FlexBelts come with various flexibilities and splices that join the belt ends. 3M™ Cloth Belt 777F has a film splice for added strength when grinding in high pressure applications. When greater flexibility may be needed to increase conformity or for a softer touch for finishing and blending, an L-flex provides more flexibility than the standard flex, and a full flex belt is the most flexible.

Applications- Moderate stock removal

- Deburring stainless steel

- Finishing stainless steel

- Surface preparation