| SKU | 7010326789 |

|---|---|

| Legacy SKU | 60440235806 |

| UPC | 00051141282138 |

| Product Number | 984F |

3M Cubitron II Roloc Disc 984F offers a superior solution for tackling metalworking applications where flexibility is required, such as weld grinding, beveling, flame-cut edge clean-up, and deburring.

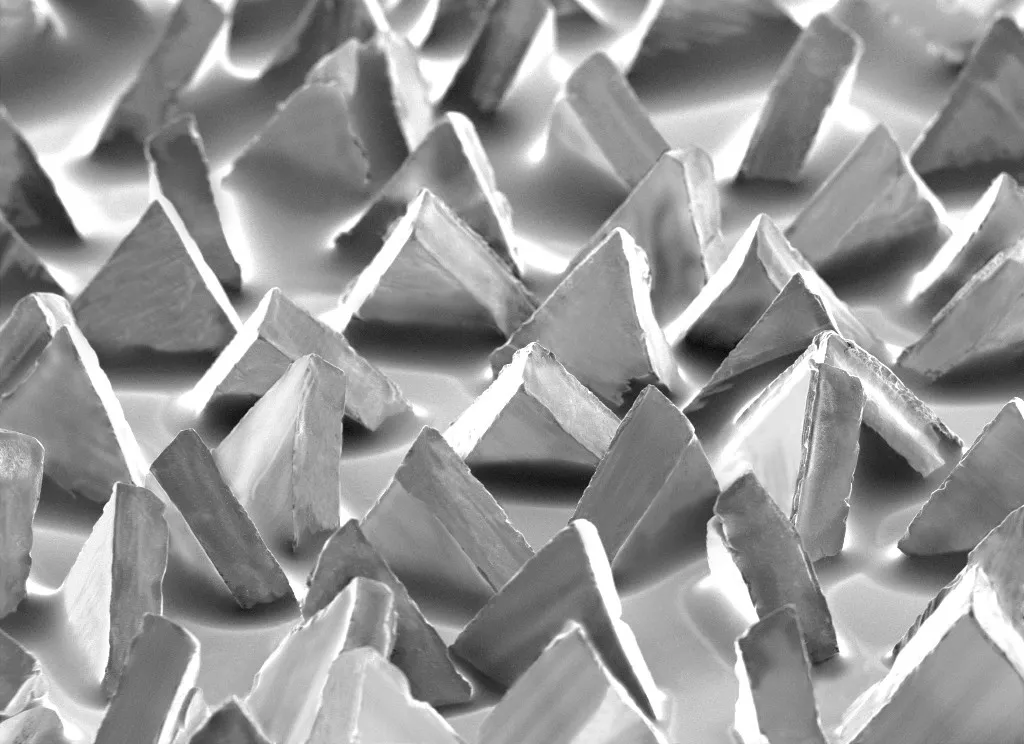

- 3M Precision Shaped Ceramic Grain (PSG) maintains super-sharp points that cut exceptionally fast with less pressure compared to conventional abrasives

- Disc life is significantly longer, completing more parts per disc and requiring fewer disc changes compared to conventional abrasives

- Grinding aid incorporated on the disc minimizes grinding temperatures for stainless steel and other heat-sensitive alloys

- Roloc™ quick attachment system provides for easy disc changes between grades or applications

- YF-weight backing supports medium to high pressure grinding applications

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2 in | 50.8 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 2.952 lb |

|---|---|

| Length | 9.70984 in |

| Width | 9.12992 in |

| Height | 5.07992 in |

| Thread Size | Non Pertinent |

|---|---|

| Maximum Speed | 25,000 rpm |

PRODUCT FAQ

-

What is 3M™ Cubitron™ II Roloc™ Disc 984F, 36+ YF-weight, TR, 2 in, Die R200P used for?

The discs are used for grinding and finishing stainless steel, mild steel and aerospace alloys.

-

How many discs are there per case of the 3M™ Cubitron™ II Roloc™ Discs?

There are a total of 200 discs included in each case with an inner pack size of fifty (50) pieces.

-

What does "TR" mean on the product description?

"TR" referred to tool attachment disc. This allows easy replacement with different grades or styles easily available.

-

Can I use this disc on a regular drill machine?

No. These particular discs required a die grinder as it provides high RPM operation needed nor its intended application purposes

-

How long does one disc last for before having to replace it?

The life expectancy may vary based on your usage pattern but our proprietary ceramic mineral formulation can cause them to last longer than standard abrasive grains when course processes such as edge chamfering is being performed which leads up two times longer lifespan comparatively speaking with other abrasives.

3M™ Cubitron™ II Roloc™ Disc 984F combines the convenience of the 3M™ Roloc™ Quick-Change Attachment System with 3M proprietary Precision-Shaped Grain (PSG) technology, delivering outstanding cut rates and disc life.

PSG contributes to an exceptionally high cut-rate with less pressure, allowing operators to finish tough tasks faster and with less fatigue. The disc is constructed on a YF weight, water-resistant 2-ply polyester backing for added durability.

A heat-activated grinding aid incorporated on the disc makes this an outstanding product for all types of metal. It helps keep the disc cooler on stainless steel and heat-sensitive metals such as nickel alloys and titanium, thereby reducing metal discoloration/oxidation and the chance of heat-related stress cracks.

To create PSG, a team of engineers started with 3M™ Ceramic Abrasive Grain and used proprietary technology to form the grains into triangular structures and electrostatically orient them on the backing to form sharp peaks that maximize cutting potential. PSG wears evenly, and because the abrasive itself stays cooler and sharper, Cubitron™ II products last significantly longer than their conventional ceramic counterparts, ensuring extended high performance in production applications.

3M™ Cubitron™ II Roloc™ Disc 984F is available for use with the following Roloc attachment system: TR. Please select discs with the attachment design made for your system.