| SKU | 7010326055 |

|---|---|

| Legacy SKU | 60440146771 |

| UPC | 00051115270772 |

| Product Number | 253FA |

3M Trizact Cloth Belt 253FA is a tough, reliable belt for flat finishing and centerless applications. Employing microreplicated aluminum oxide mineral resin-bonded on a durable, waterproof backing, this belt is available in many forms and a range of splices. It is ideal for use with metals including stainless steel, carbon steel, aluminum, nickel alloys, cobalt steel, copper and brass.

- Engineered for wet intermediate and fine finishing applications

- XF-weight polyester cloth backing supports rugged use while allowing conformability to irregular profiles

- Available in a variety of forms, widths and lengths

- Proprietary 3M-engineered abrasive mineral enhances the performance of aluminum oxide abrasive grain and reduces risk of uneven finishes

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 16.27011 lb |

|---|---|

| Length | 40.3937 in |

| Width | 11.88976 in |

| Height | 8.38583 in |

| Color | Gray |

|---|

PRODUCT FAQ

-

What is the size of the 3M™ Trizact™ Cloth Belt 253FA, A45 XF-weight, Film-lok?

The dimensions of the belt are 37 inches by 60 inches.

-

How many pieces come in one case for the 3M™ Trizact™ Cloth Belt 253FA, A45 XF-weight, Film-lok?

Each case contains five belts.

-

Is this cloth belt flexible or inflexible?

This particular cloth belt comes with No-Flex property.

3M™ Trizact™ Cloth Belt 253FA is an abrasive belt that is designed to sand scratches, gouges, dents, and stains on a range of metals without wearing easily. It is made with a tough XF-weight polyester cloth backing that has enough flex to respect surface irregularities and the stamina to withstand rugged use. These attributes make it a good match for flat or centerless finishing applications that require a sturdy abrasive that is still sensitive to surface irregularities.

This belt is available in a wide variety of forms, widths, and lengths for many different metalworking applications, as well as non-standard and make-to-order forms. It comes in grades from A100 to A6, and Trizact abrasives are graded uniquely. Grade is defined by the average particle size in microns and is indicated with an "A." Lower is finer.

Best for Wet FinishingThis belt is best for wet flat finishing and intermediate finishing of ferrous metals like stainless steel, carbon steel, as well as non-ferrous metals such as aluminum, nickel alloys, cobalt steel, copper, and brass.

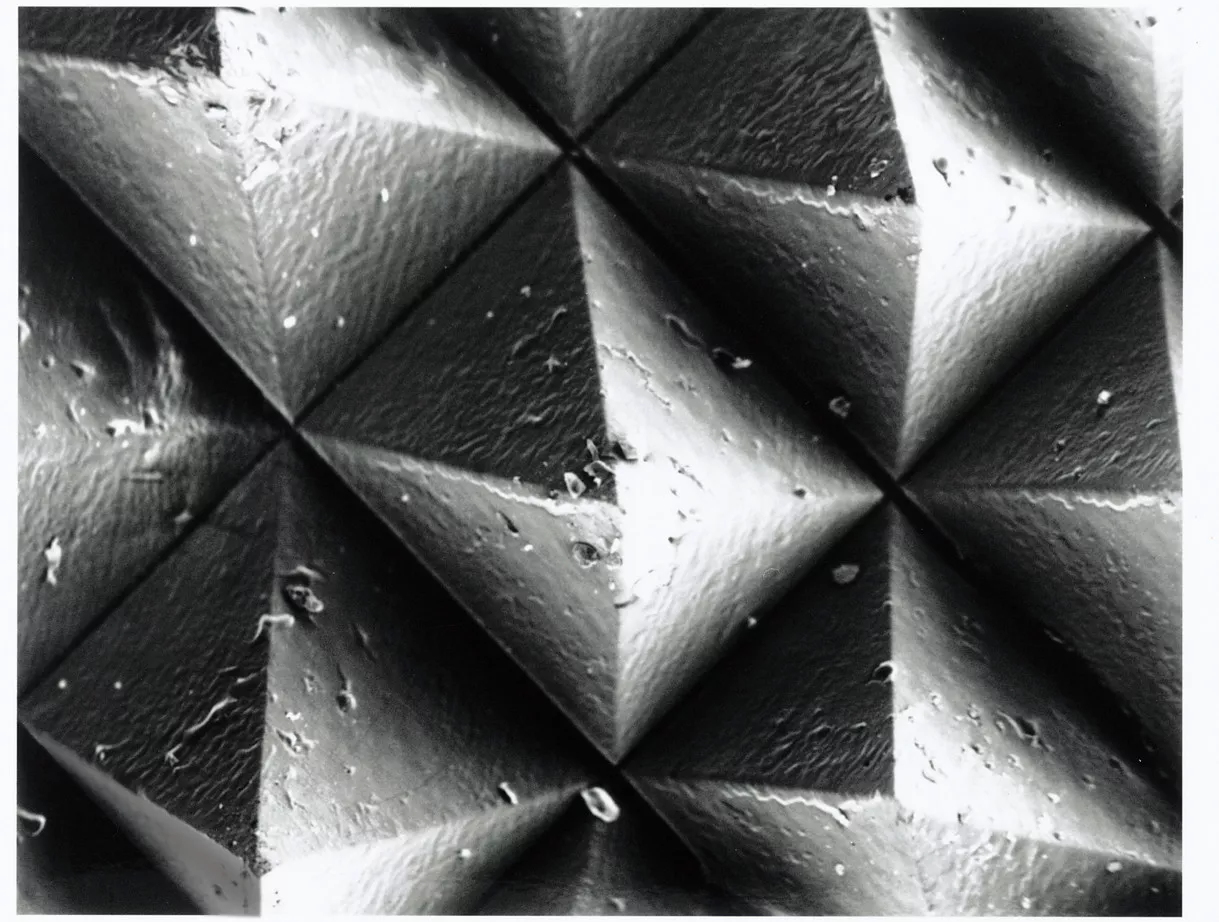

The Cutting EdgeMicroreplication is a proprietary 3M technology that involves engineering and reproducing precisely sculpted microscopic shapes, with extreme uniformity, across a surface. In the case of abrasive mineral, that surface is a cloth or film backing. As these structures break down during use, new mineral is continually exposed. The uniform configuration and spacing of 3M™ Trizact™ abrasive minerals reduces the risk of uneven finishes and contributes to consistent and predictable performance from start to finish.

From surgical tools to automotive transmission components, 3M™ Trizact™ abrasives are designed to deliver a consistent finish part after part.