| SKU | 7010299505 |

|---|---|

| Legacy SKU | 66000103631 |

| UPC | 00051115427633 |

| Product Number | 661423 |

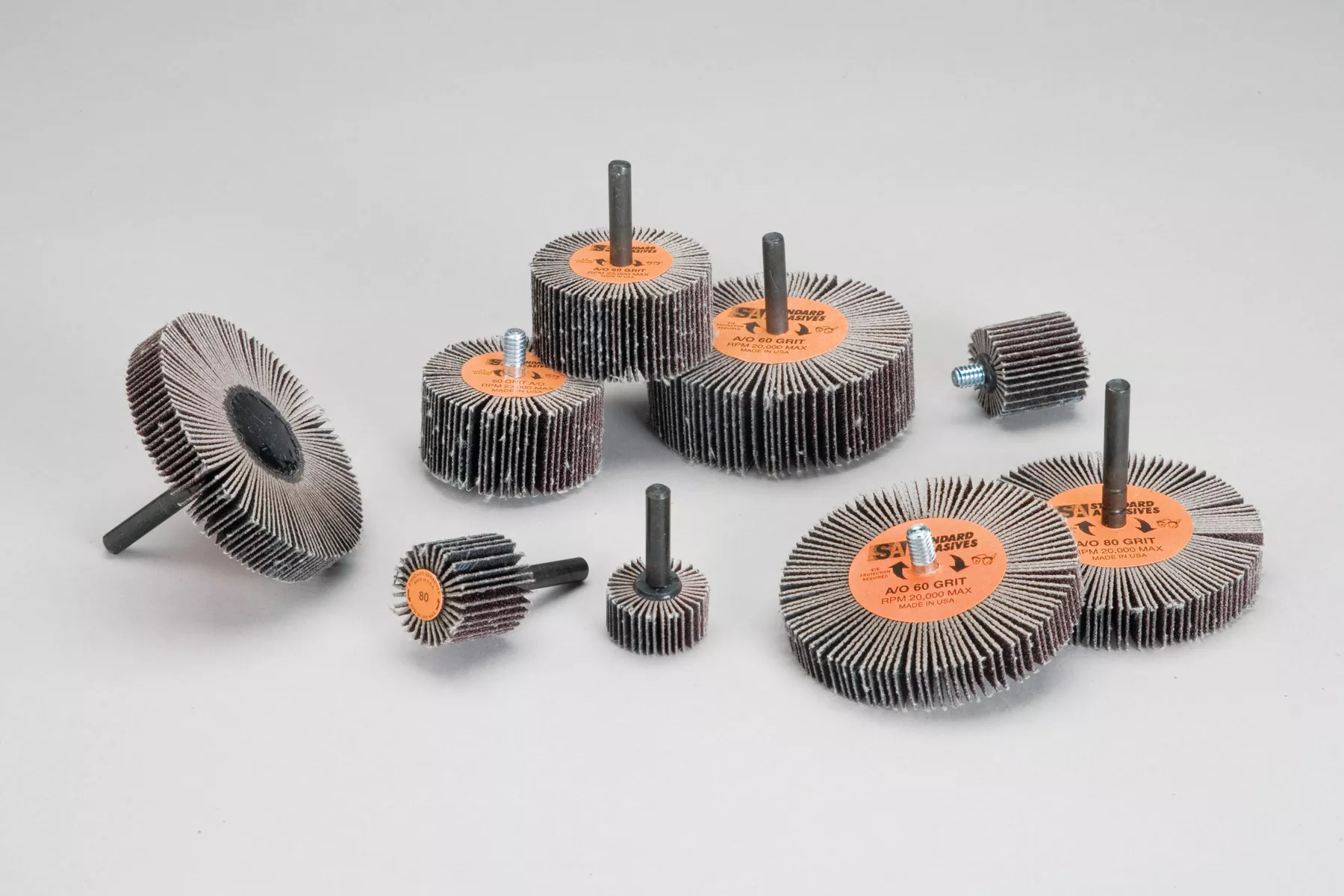

Designed to keep dust off the workpiece, the Standard Abrasives Aluminum Oxide Flexible Flap Wheel produces a straight line finish on inside diameters or contours. Use this wheel to deburr edges, remove flash, and smooth parting lines. A wide range of diameters with different attachment styles enables consistent coverage on many different workpieces.

- Flexible flaps provide excellent finish on flat and contoured surfaces

- Coated abrasive flaps clean and deburr inner diameters and contours

- Produces a linear scratch pattern

- Steel mandrel reduces chatter

- Aluminum oxide cuts quickly and suits ferrous and non-ferrous materials

- Available in a broad range of sizes and grades to suit almost any part

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Center Hole Diameter | 1 in | 25.4 mm |

Shipping Dimensions |

|

| Weight | 4.165 lb |

|---|---|

| Length | 6.5 in |

| Width | 6.5 in |

| Height | 6.75 in |

PRODUCT FAQ

-

What is the grit level of 3M's Standard Abrasives A/O Flexible Flap Wheel 661423?

The flap wheel has a grit level of 40.

-

How many pieces are included per case?

There are five flexible flap wheels included in one case.

-

What is the size of each flexible flap wheel?

The flexible flap wheel measures 6 inches by 1-inch diameter with a thickness of 1 inch.

A flap wheel is a useful tool for cleaning up burrs and parting lines on radiused or specially shaped parts where coated discs are not conformable enough or do not have the necessary reach. The Standard Abrasives™ Aluminum Oxide Flexible Flap Wheel is designed with radiused flaps that provide greater flexibility for improved finishing compared to standard Flap Wheel. The radiused flaps also brush dust away from the contact area for a cleaner work environment.

The Flexible Flap Wheel is available in smaller diameters for attachment to hand-held tools and larger diameters for off-hand applications. Some power tools may require an additional reducer bushing or adapter for attaching the wheel. A broad selection of grades is available to deburr edges, remove flash and parting lines, blend machine marks, apply a linear scratch pattern, or provide light blending, cleaning, or polishing.

Small Wheels Access Inner Radiuses and Maintain Maximum ControlWheels with smaller diameters provide access to smaller and harder-to-access inner radiuses or contours on irregular parts. They are especially useful for deburring or finishing the insides of tubing. For these smaller areas, flexible flap wheels provide a softer touch than rolls or bands, which are suitable when more aggressive material removal is required, and produce a softer finish than standard flap wheels.

These smaller wheels are 1-3˝ in diameter and have a 1/4˝ steel mandrel or a 1/4˝-20 threaded steel shank to enable fast yet secure product changeouts. In each case, the steel attachment runs the full width of the wheel center, reducing chatter in the rotation. As a result, you get a smoother finish, and the operator maintains greater control of the tool with less pressure.

Large Wheels Supply Broader CoverageFor larger hand tools or off-hand applications, flap wheels are available in diameters from 3-1/2˝ to 8˝ with 1-2˝ widths. These sizes have a 5/8˝ or 1˝ center hole compatible with larger tool arbors. The larger wheels contain more flaps per wheel for faster cutting, increased productivity, and longer life.

Durable Wheel, Fast CutAluminum oxide is a popular choice among industrial professionals because of its versatility on different surfaces, fast cut-rate, and long life. It is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives such as garnet quickly wear down with use. Aluminum oxide mineral is suitable for a wide variety of materials, including ferrous and non-ferrous metals.

Quality Standard Abrasives™ Products for Industrial ApplicationsThe Standard Abrasives brand has supplied quality abrasives to the metalworking industry for over 50 years. Customers rely on a broad array of high-performance products, including coated, bonded, and non-woven abrasive lines.