| SKU | 7010299315 |

|---|---|

| Legacy SKU | 61500164266 |

| UPC | 00048011934808 |

Scotch-Brite High Strength Sheet combines abrasive mineral with springy non-woven nylon fibers to create a unique High Strength material, which is ideally suited to deburring, satin finishing and cleaning.

- Sheet may be shaped to meet project needs and be used with a hand block or inline sander

- Available in a range of grades and minerals, so operators can choose the right combination for their application

- May be used on a variety of metals for superior versatility

- Open web is load resistant, prolonging abrasive service life

- Open web is spongy and responsive, minimizing gouging of the workpiece

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 2.5 lb |

|---|---|

| Length | 14.5 in |

| Width | 14.4 in |

| Height | 11 in |

| Color | Maroon |

|---|

PRODUCT FAQ

-

What is the Scotch-Brite™ High Strength Sheet used for?

The Scotch-Brite™ High Strength Sheet is designed to be used on metals, plastics, ceramics, and other materials. It cleans and finishes surfaces smoothly, thoroughly removing rust or surface contaminants.

-

How many sheets are included in one case of Scotch-Brite™ High Strength Sheet?

There are 100 high strength sheets included in each case of the product. This allows you to have plenty of supplies for your use.

-

What kind of surface does Scotch-Brite™ High Strength Sheet work best on?

The Scotch-Brite™ High Strength sheet works great to remove coarse grind lines left by belt sanders or rotary sanders. It's perfect for polishing flat surfaces as well as tight corners and hard-to-reach places!

One of the best attributes of the Scotch-Brite™ High Strength Sheet is that it may be cut and converted to meet specific project needs. It may even be used by hand with a sanding block in order to access hard-to-reach workpiece areas. The material may also be cut and fastened to an inline sander, so operators who want to cover more surface area can do so with the help of this tool.

Choosing the Right High Strength SheetWhen considering the aggressiveness of different Scotch-Brite™ materials, High Strength falls in the middle to high end of the spectrum.

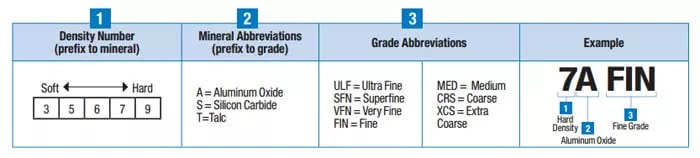

Four mineral variations of High Strength material exist: A VFN (very fine grade aluminum oxide), S VFN (very fine grade silicon carbide), A FIN (fine grade aluminum oxide) and A MED (medium grade aluminum oxide). Regardless of variation, the mineral is interspersed on non-woven nylon fibers using resin. The resin bond strengthens the abrasive, making it more tough and durable. The type of mineral and grade play an important role in determining the abrasive's aggressiveness. A VFN and S VFN minerals cut less aggressively and leave softer scratch patterns, making them good matches for moderate cleaning and surface finishing. A MED cuts more aggressively and leaves a coarser scratch pattern, making it a good match for heavy cleaning and setting finishes.

The Many Benefits of Open-Web AbrasivesNon-woven technology makes the Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity.

Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance and extremely long service life. From aesthetic finishing to weld blending, deburring and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.

- May be cut and converted to meet specific project needs

- May be used by hand with a sanding block

- May be cut and fastened to an inline sander

- Four mineral variations of High Strength material exist: A VFN, S VFN, A FIN, and A MED

- Non-woven technology makes the Scotch-Brite™ industrial abrasives unique

- Spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils and contaminants

- Gaps in the web allow swarf to escape, so debris does not clog the mineral

- Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance and extremely long service life