| SKU | 7010298892 |

|---|---|

| Legacy SKU | 60440164832 |

| UPC | 00051119844801 |

| Product Number | 407EA |

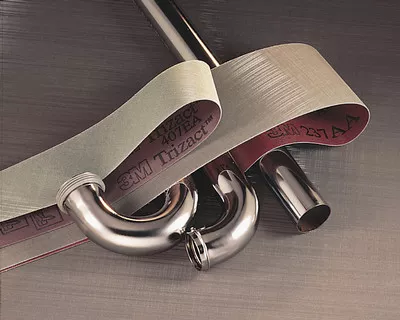

3M Trizact Cloth Belt 407EA effectively blends and polishes a variety of metal substrates during light-pressure dimensioning and finishing.

- Used commonly in aerospace, orthopedic implant and surgical instruments, plating and polishing industries

- Grinding aid lowers operating temperature for low-to-medium pressure applications, reducing the risk for part discoloration

- Ideal for use on titanium and works well with a stroke / platen sander

- Available in grades A110, A90, A60 and A20

- Trizact™ abrasives can last up to five times longer than conventional abrasives

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 2.0999 lb |

|---|---|

| Length | 9.13386 in |

| Width | 7.12598 in |

| Height | 5 in |

PRODUCT FAQ

-

What is the grit size of the 3M™ Trizact™ Cloth Belt 407EA?

The grit size of the 3M™ Trizact™ Cloth Belt 407EA is A110.

-

How long and wide is this cloth belt?

This cloth belt comes in a length of half an inch and a width of twelve inches.

-

Does it have any attachment mechanism for sanding machines?

Yes, it features a Film-lok technology that allows easy attachment to sanding machines.

-

How many pieces does one case contain?

One case contains two hundred (200) pieces.

-

Can I use this product for both dry and wet applications?

: Yes. Whether you're doing dry or wet work, the Full-flex feature makes this cloth belt adaptable to your needs.

3M™ Trizact™ Cloth Belt 407EA is designed for low to medium pressure applications. It is an abrasive that cuts sharp yet conforms to the substrate. The abrasive features a grinding aid that helps it run cool, reducing the risk for discoloring or warping the substrate due to heat. It is available in a range of grades, descending from A110 to A20. The flexible JE-weight backing enables the abrasive to follow surface contours and respond to surface imperfections for a superior finish.

3M™ Trizact™ abrasives are known for revitalizing light dimensioning and finishing work by helping to reduce processing steps, increasing throughput and creating consistency. These big benefits are achieved through a patented 3M technology called microreplication. During microreplication, small three-dimensional structures resembling pyramids are adhered to a backing. These "pyramids" contain layers of mineral, and they begin to break down after repeated use, continually exposing fresh mineral. The cycle of mineral renewal sustains the abrasive's sharpness. Ongoing sharp cutting action reduces the need to swap out the abrasive, contributing to higher throughput and increased productivity.

Moreover, because the mineral is uniformly distributed over the abrasive surface, the workpiece receives fixed – rather than erratic– contact for a consistent cut. From medical implants to surgical tools to automotive transmission components, 3M™ Trizact™ abrasives are uniquely suited for projects with acute technical requirements – delivering a consistent finish part after part.

Key Features:- Designed for low to medium pressure applications

- Cuts sharp yet conforms to the substrate

- Flexible JE-weight backing enables the abrasive to follow surface contours and respond to surface imperfections for a superior finish

- Grinding aid helps it run cool, reducing the risk for discoloring or warping the substrate due to heat

- Available in a range of grades, descending from A110 to A20

- Patented 3M technology called microreplication sustains the abrasive's sharpness

- Ongoing sharp cutting action reduces the need to swap out the abrasive, contributing to higher throughput and increased productivity

- Uniformly distributed mineral over the abrasive surface provides fixed contact for a consistent cut

- Uniquely suited for projects with acute technical requirements