| SKU | 7010295406 |

|---|---|

| Legacy SKU | 70006287380 |

| UPC | 00021200447761 |

| Catalog Number | 9824 |

| Product Number | 9824 |

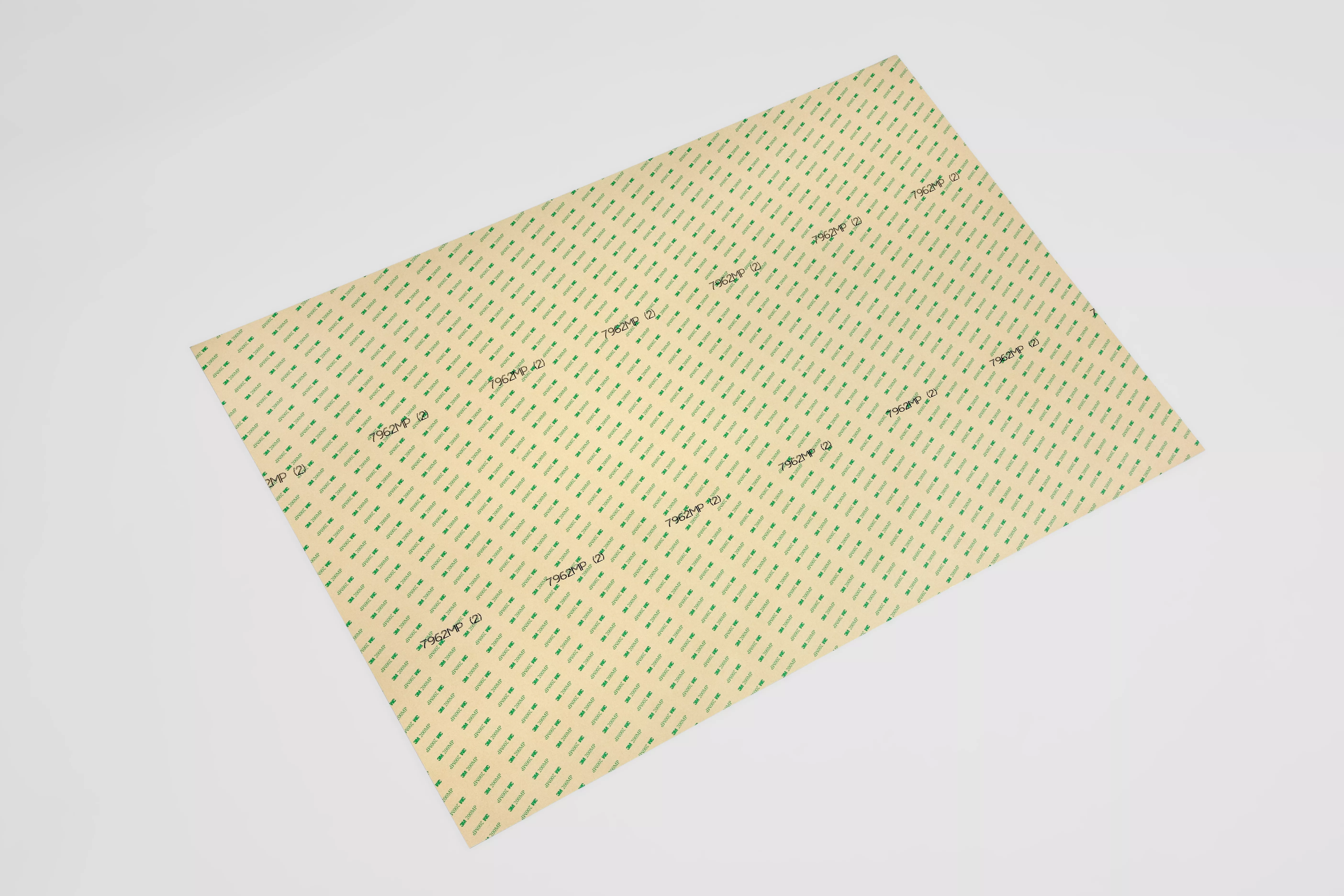

3M Double Coated Tape 9824 is a high initial tack double coated tape on a .5 mil clear polyester film (PET) carrier and with a 3.2 mil white 55-lb densified kraft (DK) paper liner. 3M High Tack Acrylic Adhesive 340 provides good adhesion to many metals, plastics and foams.

- Medium tack to high surface energy materials such as foam and other substrates

- 0.5 mil clear PET carrier adds dimensional stability

- Good temperature, chemical and humidity resistance

- Caliper-controlled 55# hard liner for consistent base in rotary printing and die cutting of labels

- Good shear and bonding characteristics

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Thickness | 2.3 mil | 0.079 mm |

Shipping Dimensions |

|

| Weight | 126.99949 lb |

|---|---|

| Length | 57.3622 in |

| Width | 11.06299 in |

| Height | 11.06299 in |

| Color | Transparent |

|---|

PRODUCT FAQ

-

What is the thickness of 3M™ Double Coated Tape 9824, Clear?

The tape is 3.1 mil thick.

-

How wide is the roll of the tape?

The roll is 54 inches wide.

-

How long and how many rolls come in a case of this product?

There are 250 yards of tape on each roll, and there's one roll per case.

-

Is this double coated tape optically clear or does it have a frosted/milky appearance to it?

. It has an optically clear finish which makes it ideal for applications that require transparency or invisibility from adhesive bonds without unsightly rivets, screws, bolts or welds.

3M™ Double Coated Tape 9824 is engineered with adhesive on both sides of the polyester film carrier, providing good chemical resistance and offering an excellent continuous temperature resistance range from -40°F to 120°F (-40°C to 49°C). The ideal tape application temperature range is 70°F to 100°F (21°C to 38°C). It is not recommended to apply the tape to surfaces at temperatures below 50°F (10°C) because the adhesive becomes too firm to adhere readily. Once properly applied, low temperature holding is generally satisfactory.

Recommended Applications- General purpose foam and fabric lamination

- General purpose lamination for fabricated parts

3M™ Double Coated Tape 9824 features 3M™ Adhesive 340 on both the face and back sides – a medium-firm acrylic adhesive that provides high initial adhesion to a wide variety of surfaces, including high surface energy plastics. A clear polyester film carrier between the adhesive layers adds dimensional stability for easier handling during slitting and die-cutting.

What is Double Coated Tape?Double coated tape is composed of a paper, film, or tissue carrier that is coated on both sides with pressure sensitive adhesive. The adhesive is protected by a peel-away liner that is removed at the time of application. These tapes can be applied by hand or with a dispenser. Double coated tape dispensers are available in a variety of configurations ranging from manual to fully automatic. Applications for double coated tape are found in electronics, automotive, aerospace, general industrial, and fabrication markets.

Double coated tapes offer a multitude of advantages over mechanical fasteners or liquid glues, including an even regular bond without gaps, reduced risk of corrosion, fast application, more flexible product design, improved appearance and they are frequently more economically efficient.

Bringing Better Ideas to the Surface through Science and Innovation3M Industrial Adhesives and Tapes Division applies the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, these technologies and expertise help deliver competitive products to the market faster and more efficiently.