| SKU | 7010294724 |

|---|---|

| Legacy SKU | 61500020773 |

| UPC | 00048011018102 |

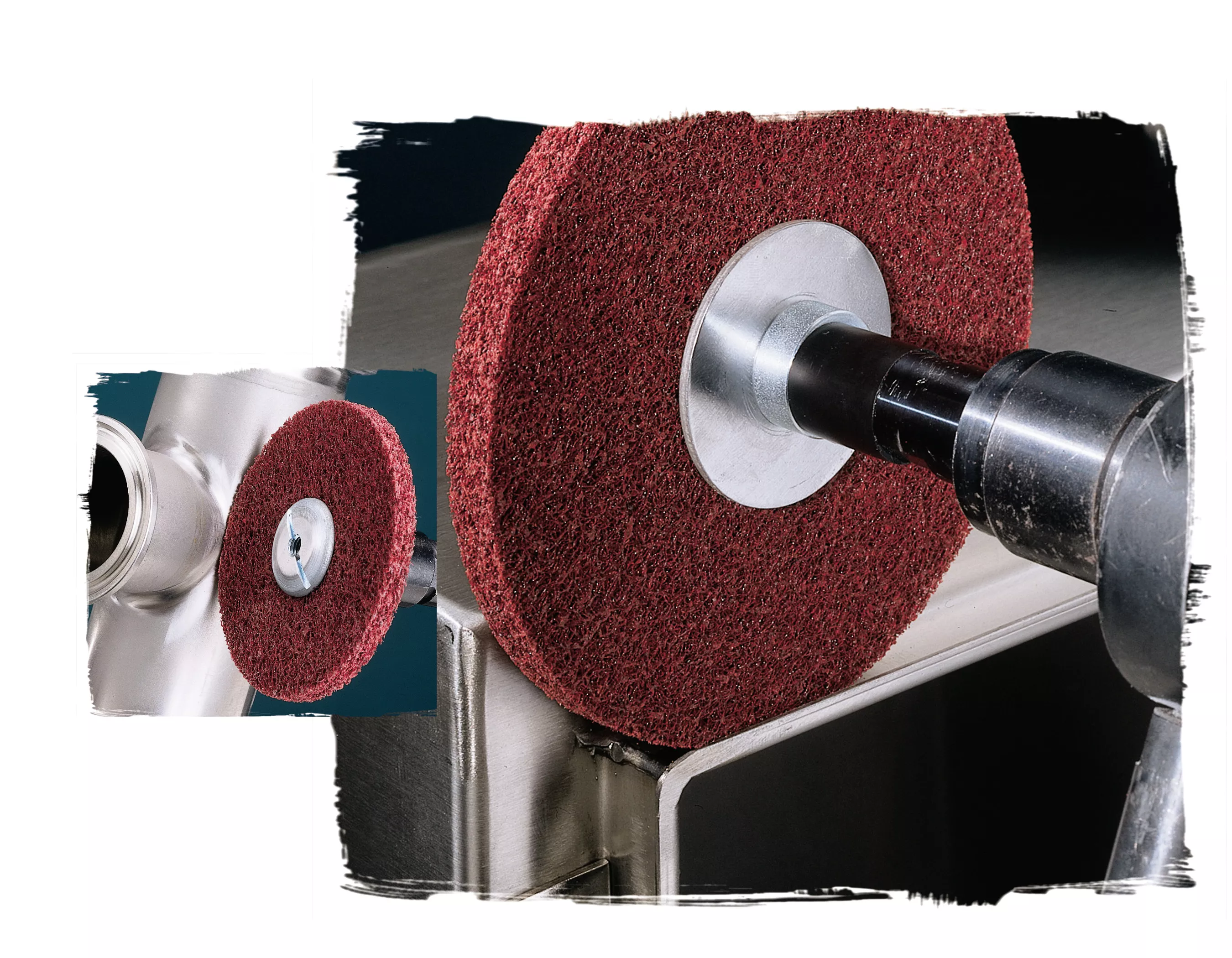

Scotch-Brite SST Unitized Wheels offer the same advantages as the SST convolute wheels. Softer and more conformable than many other higher density wheels, the SST is ideal for deburring and finishing demanding alloys like stainless steel and titanium. Unitized wheels can be made in much smaller diameters and widths than convolute wheels for more precise applications.

- Tough, layered unitized construction operates clockwise or counterclockwise

- Resists loading and runs cool, extending life of the wheel

- Perfect for very narrow widths and/or small diameters

- Higher densities retain conformability for finishing intricate shapes and contours

- Easy to run on smaller and portable equipment

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 1/2 in | 12.7 mm |

Shipping Dimensions |

|

| Weight | 1.952 lb |

|---|---|

| Length | 6.7 in |

| Width | 6.7 in |

| Height | 3.1 in |

| Color | Gray |

|---|---|

| Maximum Speed | 7,500 rpm |

PRODUCT FAQ

-

What is the purpose of the Scotch-Brite™ SST Unitized Wheel?

The Scotch-Brite™ SST Unitized Wheel is designed to deburr and finish metal parts.

-

How big is the wheel size?

It has a 6 inches diameter, 1/4 inch thickness, and a 1/2 inch arbor hole.

-

What does "7S FIN" mean?

“7S FIN” refers to its grade or coarseness. This unitized wheel has very fine abrasives that provide excellent finishing results.

-

How many units are there in one case?

Each case contains eight (8) wheels that you can use for your business needs.

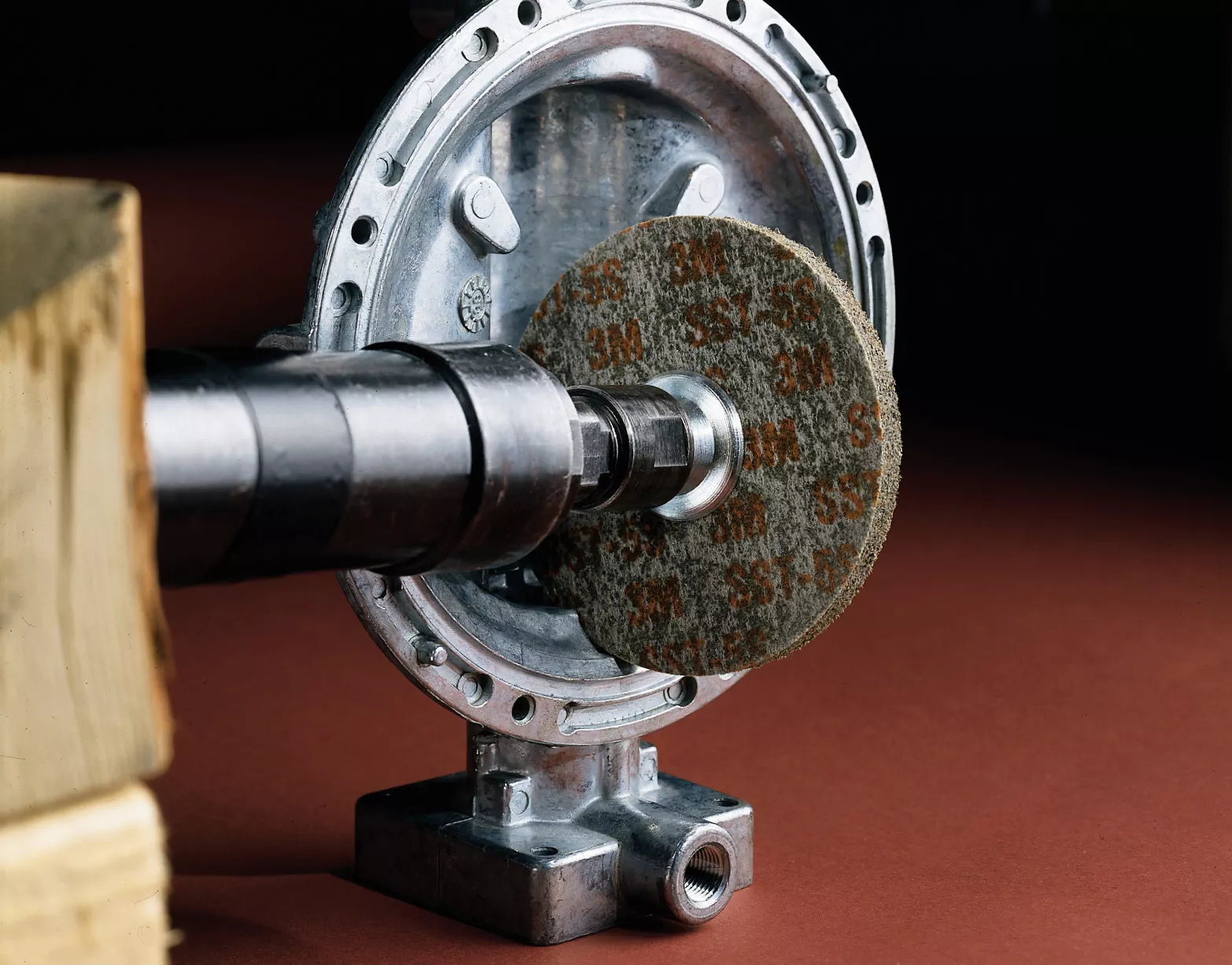

Scotch-Brite™ SST Unitized Wheels are designed to remove burrs from stainless steel, titanium, and other demanding alloys. These wheels provide uniform and repeatable results in applications requiring narrow widths and/or smaller diameters. They are perfect for removing burrs left behind from machining operations like drilling, stamping, and punching. These wheels are also great for hard to reach areas, intricate geometries, precision edges and surfaces, and high-value materials.

The aerospace industry extensively uses Scotch-Brite™ SST Unitized Wheels to deburr and finish aircraft engine components. They are also used to finish parts used in medical devices and surgical instruments and for mold and die polishing.

Scotch-Brite™ SST Unitized Wheels are available in three densities with silicon carbide or aluminum oxide abrasive mineral. This unitized version of the SST wheel runs well on bench motors, floor lathes, portable power tools, and other smaller equipment.

Scotch-Brite™ uses proprietary technology to bind synthetic fibers and abrasive particles to create an abrasive system that delivers consistent results for the life of the product. The open web construction continually exposes fresh abrasive to the work surface, for a consistent finish.