| SKU | 7010291362 |

|---|---|

| Legacy SKU | 66000035445 |

| UPC | 00051115359446 |

| Product Number | 811410 |

High Strength non-woven nylon material ensures that the Standard Abrasives Buff and Blend HS Disc maintains stiffness and won't tear or fray when faced with challenging edgework or irregular surfaces. Within the Standard Abrasives Buff and Blend product line, the HS Disc offers the best performance for cleaning and light deburring while achieving a final finish or polished piece.

- High strength (HS) Buff and Blend material delivers the best results for light deburring and final finishing

- Dense, stiff construction withstands high pressure without folding over, improving productivity

- Produces a uniform, consistent, smear-free finish on ferrous and non-ferrous metals

- Aluminum Oxide mineral cuts sharp, helps produce a consistent scratch pattern, and works well on many different metals

- Flexible, pliable open web removes burrs and surface contaminants without gouging the substrate

- Open web is load resistant, limiting buildup of debris that can clog the abrasive and prolonging service life

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 5.99878 lb |

|---|---|

| Length | 10.3748 in |

| Width | 10.3748 in |

| Height | 10.75 in |

| Color | Blue |

|---|---|

| Thread Size | Non Pertinent |

PRODUCT FAQ

-

I would be happy to help with that. Here are some questions and answers

What is the size of the Standard Abrasives™ Buff and Blend HS Disc, 811410?

-

The disc size is 4 inches.

How many discs come in a bag?

-

There are 10 discs per bag.

How many bags are included in a case?

-

There are 100 discs per case, which means there are 10 bags in each case.

What does "MED" stand for on the product description?

-

"MED" stands for medium grade, indicating the level of abrasiveness of the disc.

What materials can the Standard Abrasives™ Buff and Blend HS Disc be used on?

-

This disc is versatile and suitable for use on a variety of metals like stainless steel, brass, aluminum, as well as plastics and composites.

Among the four Standard Abrasives Buff and Blend materials, HS material is the most stiff, durable, and aggressive. It is specifically designed for irregular-shaped parts such as pipe threads, molded glass containers' edges, and non-ferrous die cast molded parts. The Standard Abrasives Buff and Blend HS Disc effectively removes small, stubborn burrs and cuts sharp to produce a consistent finish. Its non-woven construction allows it to be responsive to contours and extrusions, minimizing the risk of gouging or marring the substrate while achieving an aggressive cut.

The HS Disc features aluminum oxide abrasive grain bonded to nylon strands, resulting in a uniform scratch pattern that is perfect for satin or grain finishing. It is suitable for final finishing on various materials including brass, steel, bronze, pewter, stainless steel, and plated plastics. For off-hand applications, the discs can be ganged on a shaft to form a wheel.

For a very fine high luster and decorative finish on pieces like builders hardware, the HS Disc is available in MED or VFN grade. If a faster cut or coarser finish is required, the CRS grade disc is recommended. The CRS disc's coarser scratch pattern also makes it ideal for satin and grain finishing applications, as well as blending and cleaning surface imperfections.

HS Coarse Features and Applications- Produces a uniform, coarse finish similar to Surface Conditioning material

- Capable of withstanding high contact pressure without folding over when run as a plain disc

- Easily finishes contoured parts

- Durable enough to finish edges and welds

- Satin and grain finishing of metal surfaces

- Blending and cleaning surface imperfections

- Blending out tool marks

- Markets include stainless steel fabricators, plumbing fixtures, metal fabricators, door hardware, food equipment manufacturers, builder's hardware, aluminum extruded products, and aerospace

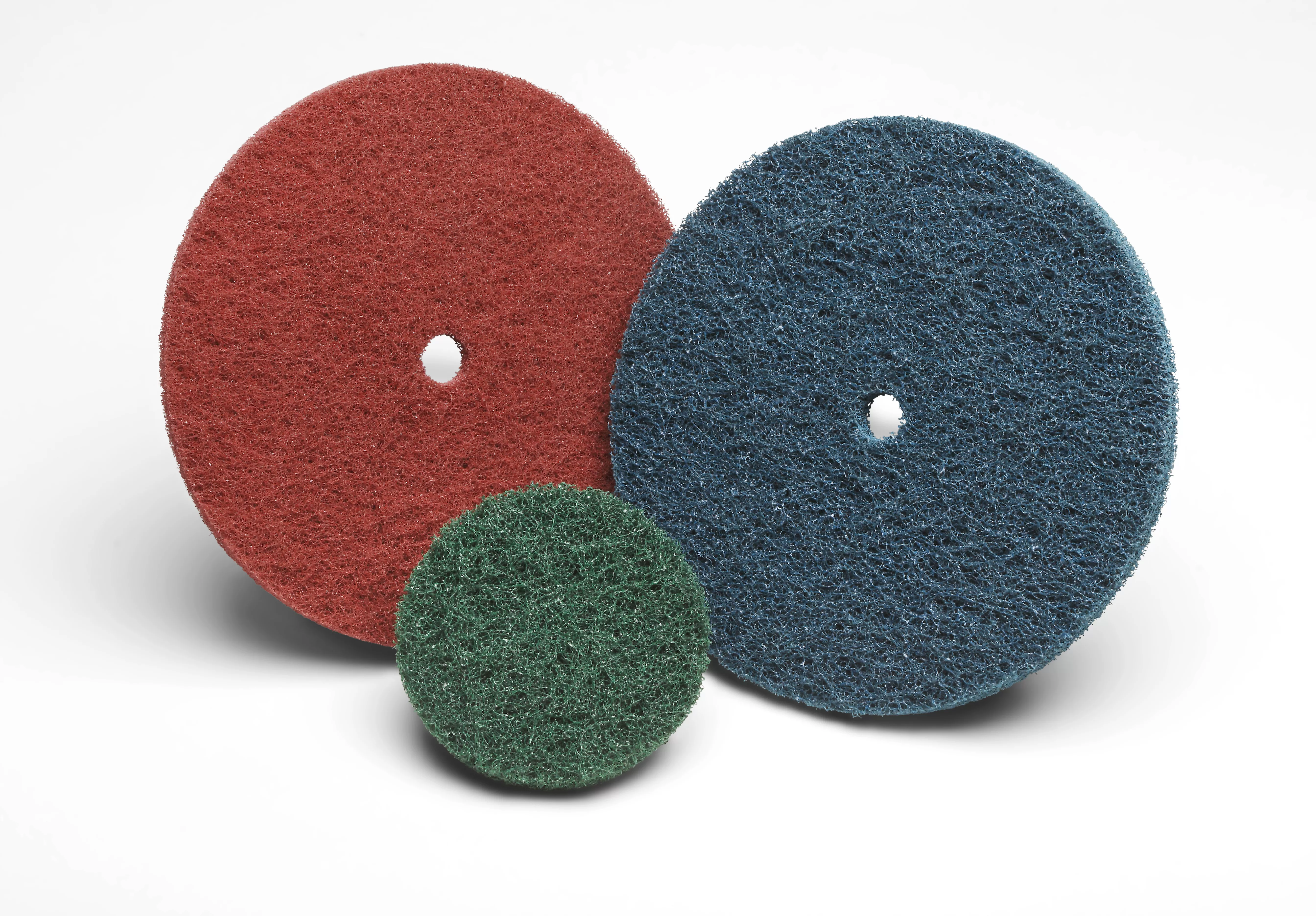

- Color: Green

- Rigid, durable construction accomplishes edge breaking, deburring, and finishing finish edges and welds

- Satin and grain finishing of metal surfaces

- Cleaning surface contamination

- Deburring and edge breaking

- Capable of withstanding high contact pressure without folding over when run as a plain disc

- Easily finishes contoured parts

- Produces a clean finish, without irregular scratches and "sparkles"

- Markets include stainless steel fabricators, plumbing fixtures, door hardware, food equipment manufacturers, aluminum extruded products, aircraft engine manufacturers, orthopedic implants

- Color: Blue

- Excels at light deburring and final finishing of small, irregular-shaped parts

- Light edge breaking on machined or stamped parts

- Edge radiusing

- Deburring threaded parts

- Pre-finish of precious metals prior to polishing

- Markets include aerospace, aircraft equipment, foundries, machine builders, machine shops, and mold and die shops

- Color: Maroon

When a lighter-duty disc is needed or if the final finish isn't as critical, the Standard Abrasives Buff and Blend GP or HP Disc is recommended. For off-hand and automated finishing processes, the loftier Buff and Blend HS-F Disc is the ideal choice.

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives Buff and Blend products are designed to be load-resistant, ensuring a longer lifespan and optimal performance. The open web structure allows unwanted swarf to escape, preventing debris from clogging the abrasive. This allows the mineral to stay fresh, sharp, and deliver a consistent cut throughout the product's life. As the fibers break down and expose fresh mineral, the likelihood of dull or blunt mineral smearing the surface is reduced, resulting in cleaner surfaces and less re-work. Additionally, the load-resistant construction reduces manual fatigue that may occur from applying heavy pressure to a dull abrasive.

The Many Benefits of Standard Abrasives Buff and Blend Products

Standard Abrasives Buff and Blend products enhance deburring, cleaning, blending, and finishing applications by reducing finishing steps, minimizing costs, and increasing throughput. Each Buff and Blend product and grade offers unique benefits, allowing operators to choose the most suitable option for superior performance on specific applications.