| SKU | 7000122225 |

|---|---|

| Legacy SKU | 66000101478 |

| UPC | 00051115425479 |

| Product Number | 898009 |

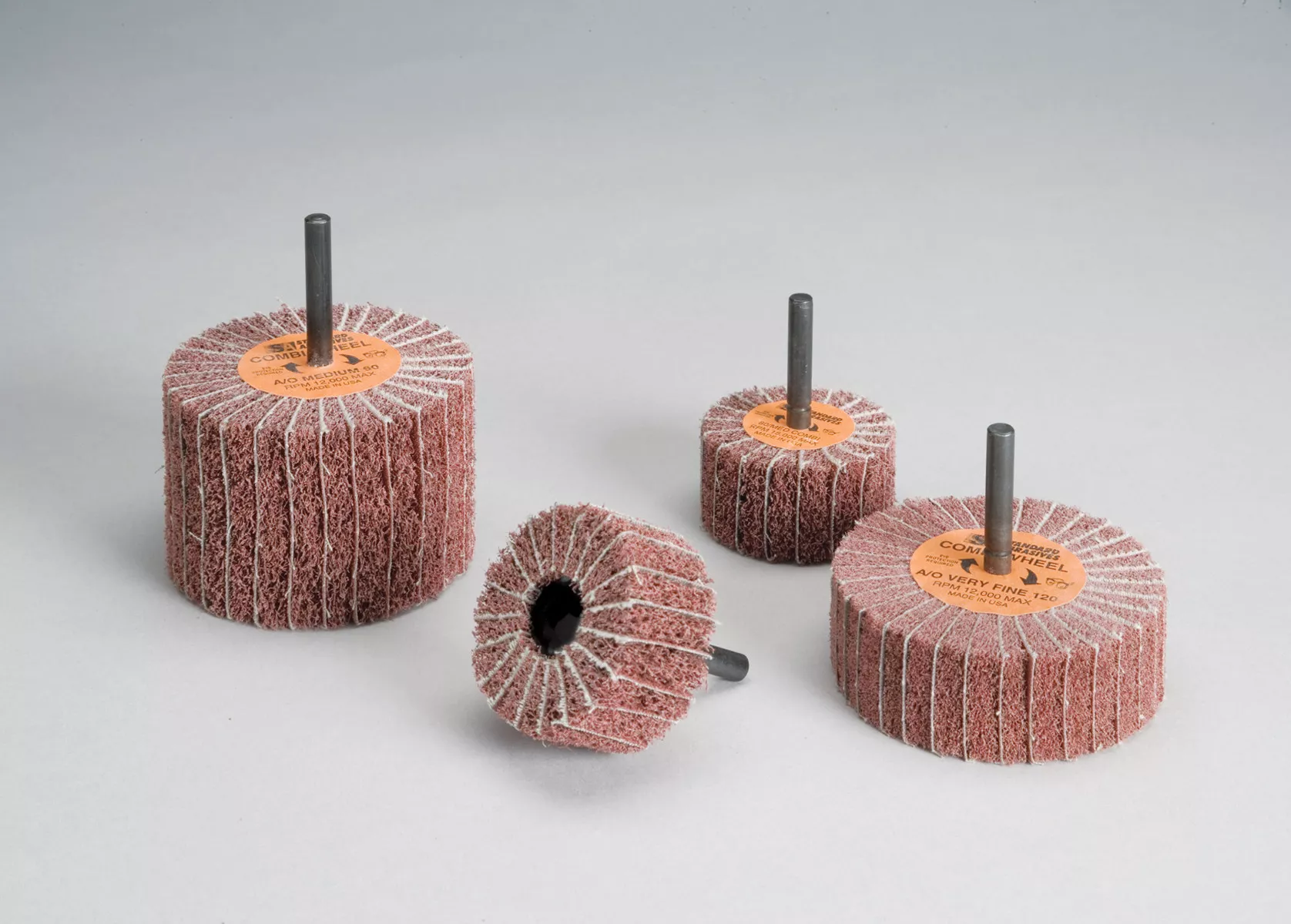

For added cut, the Standard Abrasives Buff and Blend Combi-Wheel features alternating flaps of Buff and Blend non-woven GP material and coated abrasive resin bonded material. The combination of flaps blends and removes contaminants more aggressively than a non-woven brush, while producing a uniform final finish with a linear scratch pattern.

- Blends, cleans, and finishes on ferrous and non-ferrous materials when a linear scratch pattern is required

- Useful for satin finishing on large contoured surfaces

- Resin coated non-woven mesh material runs cool and resists smearing

- 1/4˝ (6 mm) permanently affixed shank enables easy use on a small straight grinder or flat finisher (for larger wheels)

- Steel shank helps maintain smooth running and ease of control for off-hand operations

- Addition of coated flaps produces a sharper cut than a completely non-woven brush

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 3 in | 76.2 mm |

| Center Hole Diameter | 1/4 in | 6.35 mm |

Shipping Dimensions |

|

| Weight | 17.86185 lb |

|---|---|

| Length | 23.89764 in |

| Width | 9.80315 in |

| Height | 8.89764 in |

| Color | Maroon |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the 3M Standard Abrasives Buff and Blend Combi-Wheel 898009 used for?

This combi-wheel efficiently removes surface defects, rust, corrosion, light edge burrs and blending weld seams. It is an ideal product for metal fabrication applications.

-

What size is the wheel and what grit does it come in?

The wheel measures 3 inches by 2 inches by 1/4 inch and comes in Medium grade with a grit of 80.

-

How are these wheels packaged?

Each pack contains five wheels while each case has fifty durable designed inner packs ready to go out into your workflow streamlining things up.

-

Can this combi-wheel be used with any specific tool or machine?

:Yes it can! It works perfectly on bench grinders or straight shaft tools providing quick change compatibility resulting in high productivity.

The Standard Abrasives™ Buff and Blend Combi-Wheel is a versatile product that is perfect for operations where a linear scratch pattern is desired. It can be used to remove heavy oxidation before painting or plating, finish stamped or extruded aluminum parts, add a grain finish to stainless steel sheets, or create a satin finish on other large surfaces. This product is suitable for both ferrous and non-ferrous metals.

Added Strength for Demanding Finishing ApplicationsThe Combi-Wheel flaps are constructed from tough, resin-reinforced nylon fiber with aluminum oxide abrasive grain, providing aggressive, controlled action and a consistent, uniform finish. This product is more aggressive than a flap brush, which does not incorporate coated abrasive flaps, and less aggressive than a flap wheel, which is entirely constructed from coated abrasive flaps. The addition of coated abrasive flaps in a Combi-Wheel provides added abrasive strength for blending or cleaning in applications where a flap brush needs some extra teeth.

Load-Resistant Construction Boosts Life and PerformanceThe Standard Abrasives™ Buff and Blend material is load-resistant, keeping you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape, reducing debris clogging and keeping the mineral fresh. This results in a consistent cut over the life of the product, reducing the likelihood of dull or blunt mineral smearing the surface and contributing to cleaner surfaces and less re-work. Additionally, manual fatigue resulting from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Buff and BlendStandard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending, and finishing applications by helping operators reduce finishing steps, minimize costs, and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure optimal performance on specific applications. This popular product comes in a broad range of sizes and in two grades, medium (MED) and very fine (VFN), to suit a variety of large and small finishing operations.