| SKU | 7000121908 |

|---|---|

| Legacy SKU | 66000008616 |

| UPC | 00051115332609 |

| Product Number | 875144 |

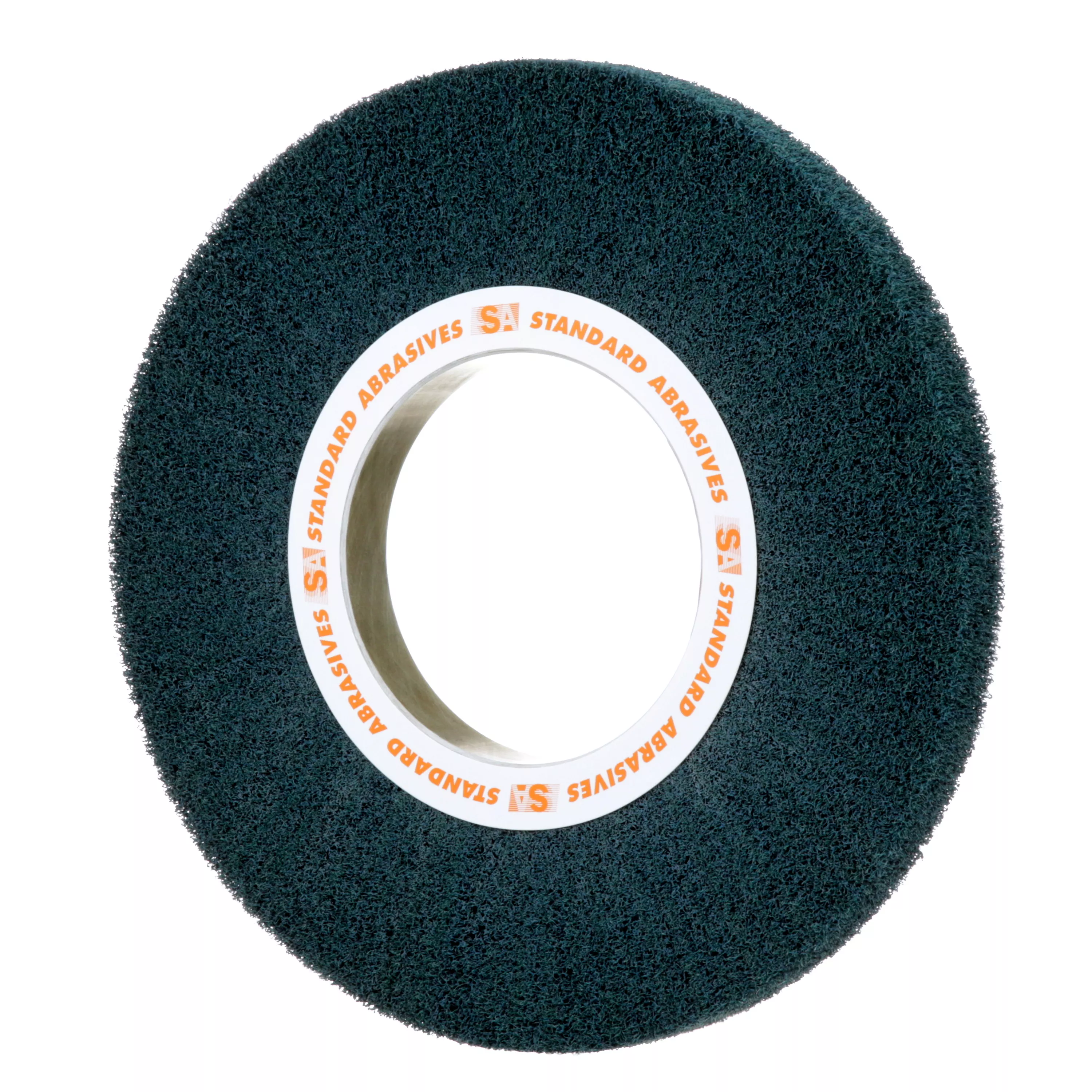

Designed to utilize the material face rather than the edge, the Standard Abrasives Buff and Blend HS-F Flap Brush helps achieve fine satin finishes without leaving lines on the workpiece. The high strength (HS) material makes it ideal for blending and finishing on stainless steel, brass, aluminum, chrome, and nickel-plated fixtures, especially where uniform and long line finishes are desired.

- Medium grade abrasive produces consistent satin finishes on stainless steel, brass, aluminum, chrome and nickel plated fixtures

- Tough nylon face removes surface contaminants without leaving lines or gouging the work piece

- High strength (HS) durability is tear-resistant and stands up to irregular shaped parts

- Resin coated surface runs cool and is waterproof for use with lubricants

- Various sizes available for wide range of tools: straight shaft portable grinder, bench motor, backstand, floor lathe, rotary, straight line, and robotic

- Blue material

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 4.7999 lb |

|---|---|

| Length | 15.47244 in |

| Width | 15.47244 in |

| Height | 5.66929 in |

| Color | Blue |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 2,500 rpm |

PRODUCT FAQ

-

What is the Standard Abrasives™ Buff and Blend HS-F Flap Brush 875144?

The Standard Abrasives™ Buff and Blend HS-F Flap Brush 875144 is a high-quality abrasive attachment that provides effective blending, finishing, and deburring capabilities.

-

What are the dimensions of this flap brush?

The flap brush measures 12 inches in length, 1 inch in width and has a height of 5 inches.

-

What type of density do these brushes offer?

. These specific brushes have medium-density bristles which provides great flexibility to enable it to surface into crevices or contours for uniform finishes.

-

How many units come in cases containing this itemization number (FB078-23-21 A MED)?

Each case contains four pieces comprising FB078-23-21 A MED - Standard Abrasives™ Buff and Blend HS-F Flap Brush.

-

What types of surfaces can I use these flap brushes on ?

The HS-F flap brush stands appropriate for metallic-based commodities like stainless steel where precision polishing is necessary but also play its part effectively with aluminum being highly malleable material while generic-purpose metals could also be considered fitting extensions over these flats .

Quality Materials Well-Suited for Deburring and Finishing Irregular-Shaped Parts

Buff and Blend High Strength products are made from tough, resin-reinforced nylon fiber with aluminum oxide abrasive grain. The durable high strength construction of the Standard Abrasives™ Buff and Blend HS-F Flap Brush provides aggressive action for the toughest applications and provides greater tear resistance, perfect for final finishing on irregularly shaped parts. Tough, non-woven Buff and Blend HS-F medium grade material allows removing surface contaminants without eliminating critical detail or gouging the workpiece. Choose from a broad offering of sizes, densities and grades to suit many different finishing operations.

Medium Grade Brush Suits Decorative and In-Line Applications

When a very fine high luster and decorative finish is desirable on pieces such as builders hardware, the blue HS-F Brush in MED grade provides the conformability you need. The Buff and Blend HS-F Flap Brush is an ideal choice for:

- A satin finish on builders' hardware (cabinet handles, door knobs, and more)

- Satin finishes on soft metals

- Highlighting and finishing aluminum extrusions (used as a quality control tool to identify defects)

- Inline brushed finishes on aluminum and stainless cookware (pots and pans)

- Producing fine scratch patterns on utensils and cutlery prior to cotton buff and compound polishing

- Removing oxide from precious metals

- Blending flash and parting lines on aluminum die cast

Featuring Consistent Finishes and Operator Comfort

Flap brushes produce a consistent finish which does not reflect lines commonly attributed with ganged arbor hole discs. Density, pressure and angle determine the ability of the flap brush to remove burrs, oxidation and handling marks. The abrasive material provides ventilation which helps dissipate heat and, therefore, runs cooler. This provides consistent finishes without smearing or otherwise discoloring the work piece. Minimal vibration can reduce chattermarks on the workpiece and can lead to less operator and machine fatigue.

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Buff and Blend products are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work.

The Many Benefits of Standard Abrasives™ Buff and Blend Products

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure superior performance on specific applications.