| SKU | 7000121385 |

|---|---|

| Legacy SKU | 62427985304 |

| UPC | 00021200253324 |

| Catalog Number | 30H |

| Product Number | 30H |

3M Fastbond Contact Adhesive 30H is a low-odor, water-based adhesive designed to deliver a high-strength, high-coverage bond with a bonding range of 4 hours. Post-formable and high-temperature-resistant, this adhesive is non-flammable in the wet state. 3M Fastbond Contact Adhesive 30H is proven to bond combinations of most foamed plastics, plastic laminate, wood, plywood, wood veneer, and canvas.

- FOR INDUSTRIAL USE ONLY: This product is designed exclusively for industrial applications

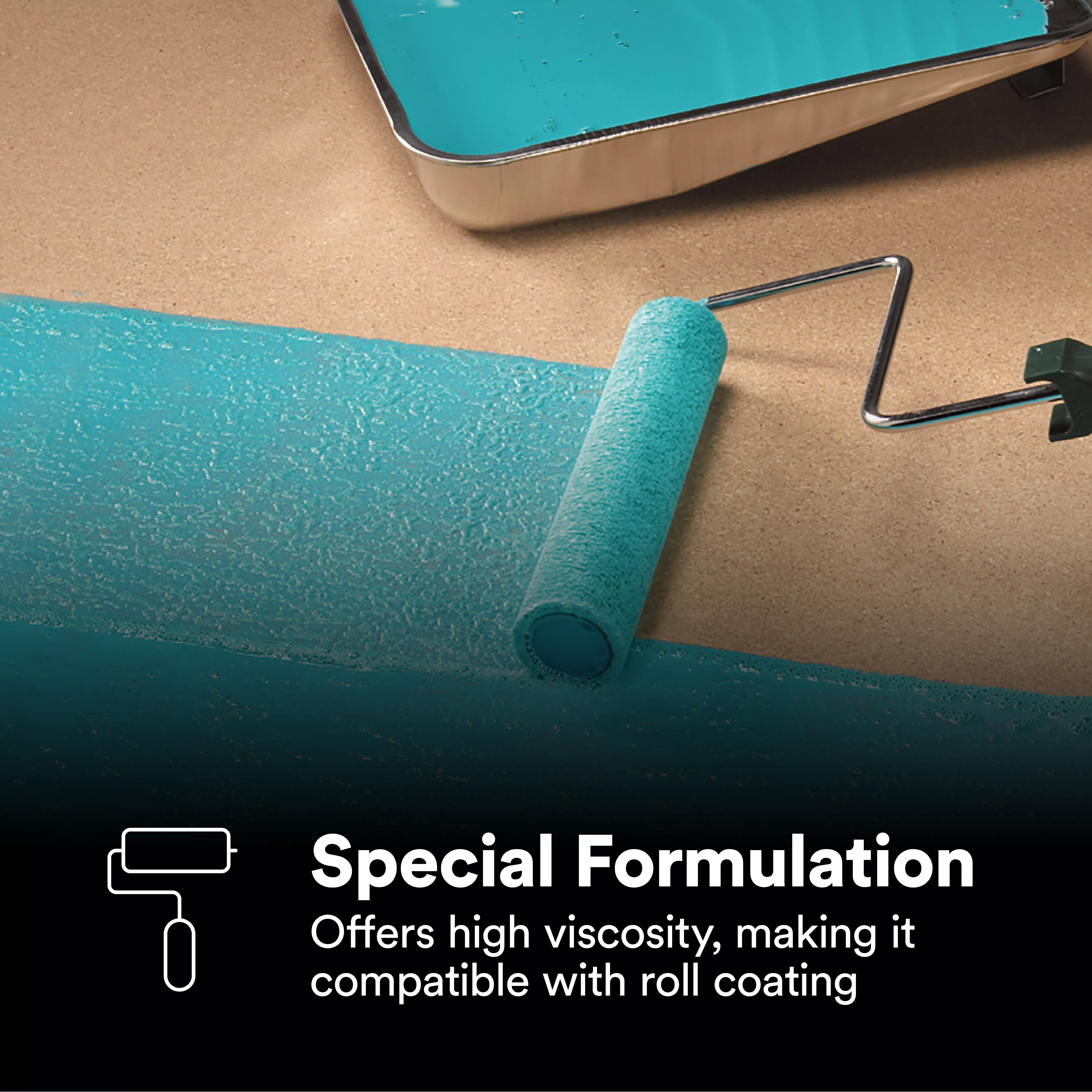

- SPECIAL FORMULATION: Offers high viscosity, making it compatible with roll coating

- ADHERES A VARIETY OF SUBSTRATES: Bonds most foamed plastics, plastic laminate, wood, plywood, and canvas

- TOUGH, RESILIENT BONDS: Creates a high-strength, high-temperature-resistant bond

- LONG BONDING RANGE: Delivers up to a four-hour bonding range

- A VARIETY OF APPLICATION METHODS: Can be applied by either brush or roller

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 48.26139 lb |

|---|---|

| Length | 11.88976 in |

| Width | 11.88976 in |

| Height | 14.56693 in |

| Color | Green |

|---|

PRODUCT FAQ

-

What is 3M™ Low Mist Contact Adhesive, Green, 5 Gallon Drum (Pail)?

3M™ Low Mist Contact Adhesive is a solvent-based adhesive that provides high immediate strength and good heat resistance. This adhesive has a very low mist formula compared to similar adhesives.

-

Where can I use this adhesive?

The 3M™ Low Mist Contact Adhesive can be used for bonding laminates, veneers, metals onto wood substrates or particle board material. It's ideal for applications where flammability is of concern.

-

Is it easy to apply with the spray gun or brush?

Yes! it can be brushed or applied using an air pressure fed conventional spray system with atomizing heads such as the IWATA LPH80 HVLP Spray Gun

-

Is there any special recommendation regarding storage and handling of the product?

:This product should be stored under sheltered conditions in dry place below +27°C temperature and less than 60% relative humidity in unopened drums/pails.

-

. How much coverage will I get from a single drum/pail?

. Coverage may vary depending on usage frequencies but with proper application techniques you should receive approximately somewhere between sixty-five (65) to seventy-five(75) square meters per five-gallon pail of bond area at recommended thicknesses which enhances its cost-effectiveness over alternatives because very less volume required per application

3M™ Low Mist Contact Adhesive 30 is a one-part, water-dispersed contact adhesive that creates a very high strength bond capable of resisting high temperatures. With a four-hour bonding range, this adhesive is post-formable, heat resistant and non-flammable in its wet state, which may help reduce risk of fire and assist with compliance for insurance regulations. The low mist formulation provides an economical, high coverage spray that maximizes the adhesive. It is ideal for decorative laminate applications where non-flammability and low VOCs are critical. However, this product is not recommended for drywall laminating or for bonding metal surfaces.

Recommended Applications- Most formed plastics

- Plastic laminate

- Wood

- Plywood

- Wood veneer

- Canvas

Formulated for success, 3M™ Low Mist Contact Adhesive 30 delivers high immediate bonding strength with a long bonding range. This design offers a great solution for bonding porous substrates to porous or non-porous substrates with time for positioning and adjustments.

Applying Your AdhesiveWhether it is being sprayed, brushed or rolled on, the application of your 3M™ adhesive is a straightforward process. Start by carefully applying your adhesive to your surface until you've formed a uniform coat. Using an overlapping pattern, the application of one coat should prove sufficient for most surfaces. Effective adhesive coverage is accomplished when 80% or more of the surface is covered. Some substrates, including porous materials, may require an additional coat. In order to apply additional adhesive, simply wait until the existing adhesive becomes dry to the touch, and then proceed with the application of the additional coat.