| SKU | 7000120985 |

|---|---|

| Legacy SKU | 61500149804 |

| UPC | 00048011277363 |

TheScotch-Brite Roloc HP High Strength Disc is an extra tough non-woven disc well suited for light dutydeburring, cleaning, and finishing applications. Engineered with increased durability and slightly less conformabilitythan the Scotch-BriteHigh Strength Disc, this disc is the best choice for heavy blending and finishing work, and the metal TSM attachment allows convenient disc swapping.

- Durable, tough disc offers extra life for high pressure tasks such as light duty deburring, heavy cleaning, and finishing

- More aggressive than the Scotch-Brite™ High Strength Disc

- Non-woven, conformable fiber construction can take on tough surfaces without marring the workpiece

- Open web is load resistant for effective use on steel and aluminum

- Aluminum oxide mineral is durable and cuts fast

- Small flexible disc enables access to small spaces

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2 in | 50.8 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 3.69936 lb |

|---|---|

| Length | 12.59843 in |

| Width | 12.48031 in |

| Height | 9.29134 in |

PRODUCT FAQ

-

What is the Scotch-Brite™ Roloc™ HP High Strength Disc TSM made of?

The disc is made from a non-woven, high-strength material with abrasive particles bonded onto the surface.

-

How long will these discs last on average?

The lifespan of these discs depends on usage, but their durable design allows them to withstand heavy-duty applications and provides extended product life.

-

Can I use these discs for wet or dry sanding applications?

Yes! These discs can be used for both wet and dry sanding and are great for deburring, finishing, blending, and cleaning various types of metals such as stainless steel or aluminum.

-

Is this 200 ea/Case package size available in any other grits besides medium (MED)?

Yes! This disc is also available in fine (FIN), very fine (VF) and extra coarse (XCS) grit sizes. Additionally, different case sizes may also be available based on your needs.

Scotch-Brite™ Roloc™ HP High Strength Disc is ideal for operations that require durability and aggressiveness over conformability. It can withstand high pressure for heavy edge work while deburring, contributing to longer service life. It also cleans and finishes without compromising the geometry of the workpiece.

Aggressive Cut with Consistent FinishingScotch-Brite™ non-woven fibers provide cool, uniform wear, and the open-web construction resists loading. The medium (MED) grade aluminum oxide provides a balance between fast cut and smooth finish. The disc is designed for use with a TSM quick change attachment system, and the no-hole center allows for the use of more of the disc surface and access to tight spaces. These attributes combine to provide consistent finishing over the life of the disc.

Fast Cut and Long LifeAluminum oxide is a tough mineral with a fast cut-rate, making it a popular choice among industrial professionals for many different applications. Due to its cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. It is suitable for use on a wide variety of substrates, including ferrous alloys.

Quick Change ConvenienceTSM quick change discs have an asymmetrical metal hub that requires just a short twist to securely lock onto a TSM disc pad (sold separately). This allows operators to conveniently change discs with a simple twist-off, twist-on motion. No tools are needed, and this quick and convenient attachment method saves operators time when switching discs between grades or applications. The TSM hub is also compatible with other asymmetrical metal hub back-up disc pads.

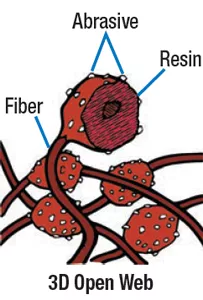

The Scotch-Brite™ AdvantageScotch-Brite™ abrasives are unique due to their nonwoven technology. The abrasive mineral is resin-bonded onto synthetic fibers, creating an open web construction. Spaces between the fibers permit excess material to escape, so the mineral does not become worn down by debris. It keeps the mineral cutting sharper longer, enhancing cut performance and increasing abrasive service life. The spring-like nature of the fibers works well on contours and responds to subtleties on the surface. Its responsive design effectively removes unwanted burrs, soils, and contaminants without ruining the base material, so you get a consistent and uniform finish – part after part.