| SKU | 7000120959 |

|---|---|

| Legacy SKU | 61500139094 |

| UPC | 00048011242491 |

| Product Number | SC-DN |

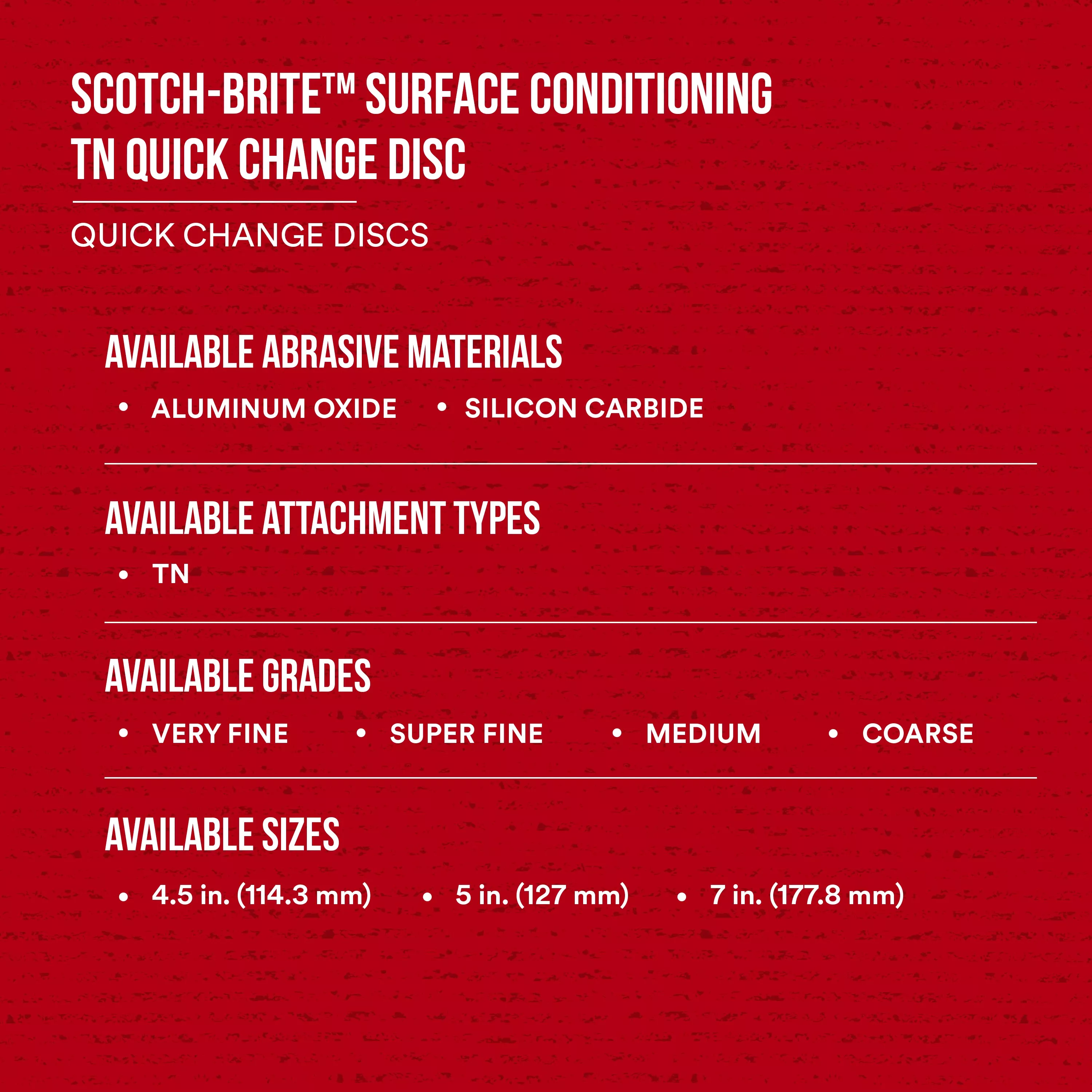

The Scotch-Brite Surface Conditioning TN Quick Change Disc combines a durable, nonwoven disc with an efficient TN quick-change attachment for an effective disc that cleans, finishes, blends and deburrs. The nonwoven fiber construction conforms well to help preserve irregular or contoured surfaces and the TN attachment makes for quick and easy disc changes.

- GREAT FOR LOW-MEDIUM PRESSURE: Built for consistency in blending, cleaning, deburring, finishing, grinding, polishing, radiusing, refining and surface preparation

- CONFORMABLE NONWOVEN WEB: Springy nonwoven fibers resist loading and conform to irregular or contoured surfaces

- WORKS ON A RANGE OF METALS: Great for use on aluminum, mild steel, nickel alloy, stainless steel and titanium

- QUICK AND EASY ATTACHMENT: TN quick change attachment system allows for fast disc changes

- CHOOSE YOUR MINERAL: Super Fine grade is powered by super-sharp silicon carbide that excels in low-pressure and fine finishing applications, while all other grades feature harder and more durable aluminum oxide

- AVAILABLE IN A RANGE OF GRADES: Choose from Super Fine (SFN), Very Fine (VFN), Medium (MED) and Coarse (CRS) to fit your application needs

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 7 in | 177.8 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 3.69936 lb |

|---|---|

| Length | 12.59843 in |

| Width | 12.48031 in |

| Height | 9.29134 in |

| Color | Maroon |

|---|---|

| Maximum Speed | 7,000 rpm |

PRODUCT FAQ

-

What materials is the Scotch-Brite™ Surface Conditioning TN Quick Change Disc best suited for?

The SC-DN, A/O (Aluminum Oxide) medium coarse grade disc is perfect for cleaning and finishing a variety of metals such as aluminum, brass, copper, stainless steel, carbon steel and other alloys.

-

Can this quick change disc be used on handheld power tools?

Absolutely. It's designed to be compatible with various types of hand-held rotary sanders which can accommodate 7 inch diameter discs including right angle grinders and orbital sanders.

-

How long does each disc last?

That depends on several factors such as the type of metal being worked on, the level of pressure applied by the operator and the actual duration or intensity of use. Generally speaking though these are durable discs that offer consistent performance throughout their lifespan and you should expect them to outlast traditional abrasives.

-

What's so special about this particular product line within 3M's family?

The entire Scotch-Brite™ portfolio are high-performance products developed specifically for surface conditioning applications. This means they produce superior-quality finishes while reducing process times up to three times faster than conventional abrasives. Our quick-change design also helps eliminate time-wasting downtime associated with attaching or detaching abrasive pads from held-hand devices making your work easier & more efficient!

Scotch-Brite™ Surface Conditioning Disc

The Scotch-Brite™ Surface Conditioning Disc uses aluminum oxide abrasive. Aluminum oxide is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

Scotch-Brite™ Industrial Abrasives

Scotch-Brite™ industrial abrasives are unique surface conditioning products with abrasives incorporated into non-woven nylon or synthetic fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.