| SKU | 7000077959 |

|---|---|

| Legacy SKU | FN510079265 |

| UPC | 00051144808007 |

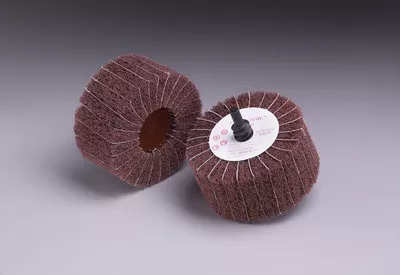

Scotch-Brite Roloc+ Combi-R Wheel is a unique finishing wheel composed of alternating Scotch-Brite non-woven flaps and aluminum oxide coated abrasive sheet. Conformable pads provide a large footprint and cushion the abrasive sheet to create a brushed, decorative finish. This wheel uses the Roloc+ quick attachment system.

- Alternating flaps of coated and non-woven material will cut and finish in a single step

- 3M™ Roloc™+ attachment system uses longer shaft

- Flexible web pads cushion each abrasive sheet to produce a professional brushed finish

- Roloc™+ attachment holds wheel securely and provides change-out without the need for attachment tools

- Choice of grades to provide desired finish (#3/#4)

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2-1/2 in | 63.5 mm |

| Center Hole Diameter | 1-1/4 in | 31.75 mm |

Shipping Dimensions |

|

| Weight | 1.62701 lb |

|---|---|

| Length | 8.30709 in |

| Width | 5.74803 in |

| Height | 3.70079 in |

| Color | Maroon |

|---|

PRODUCT FAQ

-

What makes the Scotch-Brite™ Roloc™+ Combi-R Wheel different from other wheels offered by competitors?

The Scotch-Brite™ Roloc™+ Combi-R Wheel features a durable and responsive design that produces consistent finishes on metals such as aluminum, steel, titanium, nickel alloys. It uses multiple mineral grades to enhance its abrasive action while maintaining edge durability for effective deburring, cleaning-slots edges and polishing.

-

Can this wheel be used on all types of metal surfaces?

Absolutely! This wheel is versatile enough to work effectively across most standard metal substrates such as carbon steel, stainless steel, nickel alloys generating satisfactory finishes with minimal effort.

-

Could you tell me about how long each wheel tends to last before having to be replaced?

Although it somewhat varies depending on the job task at hand and applied pressure during use. We tend to provide conservative estimates regarding product life span in our packaging and typically recommend replacing them after their surface has become clogged or worn down.

The Scotch-Brite™ Roloc™+ Combi R Wheel is a versatile surface finishing and blending tool that can be used on a variety of surfaces such as aluminum, stainless steel, copper, and brass. Its longer shaft provides stability and reduces side-loading, helping it remain perpendicular to the work surface.

Aluminum Oxide Abrasive MineralThe Scotch-Brite™ Roloc™+ Combi-R Wheel uses aluminum oxide abrasive mineral, which is a popular choice among industrial professionals due to its cut-rate and long life. This mineral is tough, durable, and self-fractures to expose fresh cutting edges during use. It is widely used in grinding applications in addition to sanding and finishing use due to its high cut-rate, hardness, strength, and low heat retention. Aluminum oxide is suitable for use on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

Scotch-Brite™ Industrial AbrasivesScotch-Brite™ industrial abrasives are unique surface conditioning products that incorporate abrasives into non-woven nylon or synthetic fibers. This combination creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.