| SKU | 7000046244 |

|---|---|

| Legacy SKU | 61500292448 |

| UPC | 00048011603322 |

| Product Number | GB-DH |

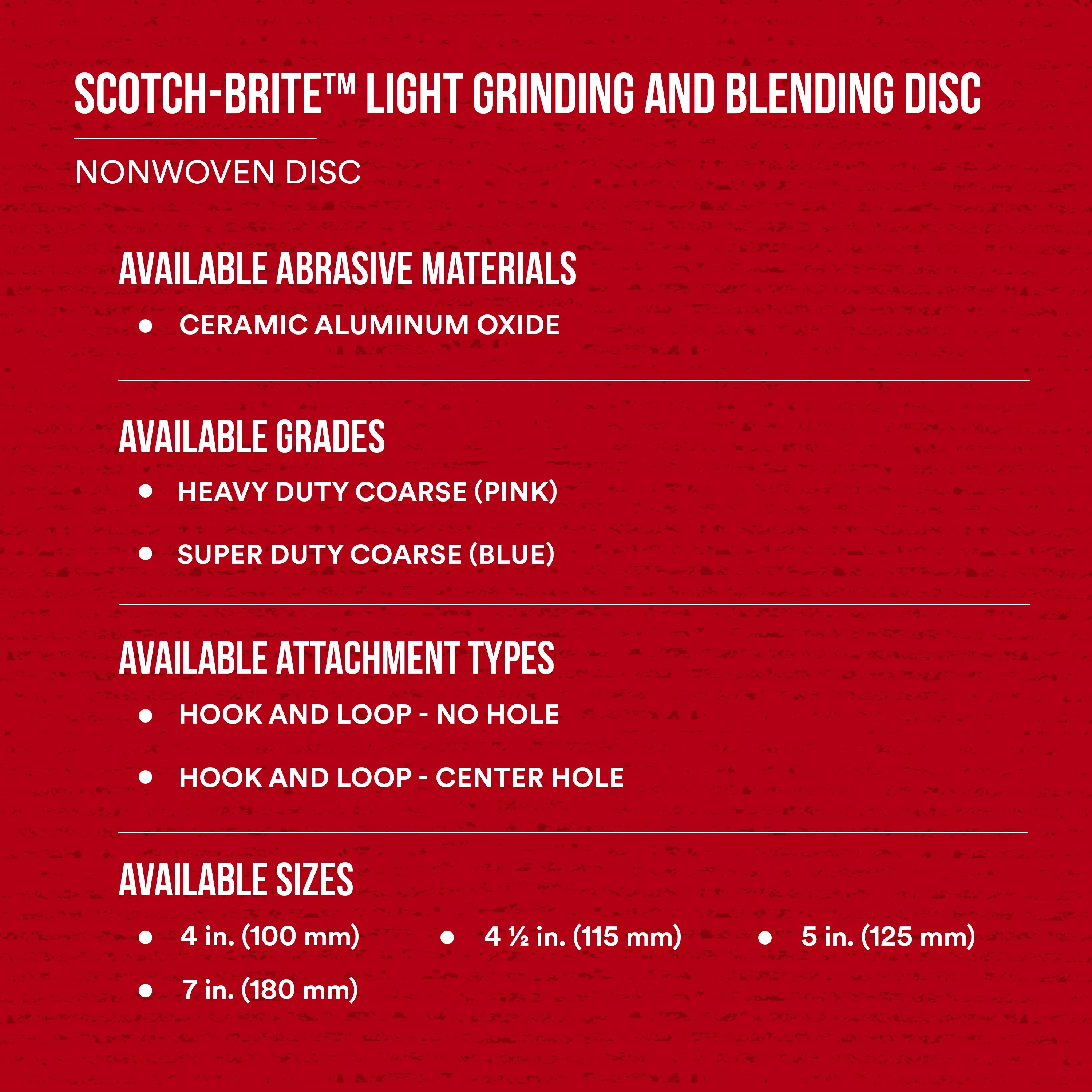

Scotch-Brite Light Grinding and Blending Disc uses a ceramic abrasive grain blend to achieve a high cut-rate for optimal weld grinding and blending in mild-steel applications. In these instances, Light Grinding and Blending discs are designed to effectively blend and refine a grade 36 scratch or finer.

- EASY ONE STEP: Blends and preps for paint at the same time in a single, efficient step

- HIGH PERFORMANCE: High cut rate and blending ability enhances productivity

- LONG LASTING: Strong disc backing provides high edge durability for an extended disc life

- RECOMMENDED APPLICATIONS: Blending, Grinding, Refining, Deburring

- LONG-LASTING DURABILITY: Engineered to resist edge wear for longer disc life

- FAST, CONSISTENT CUT: Ceramic aluminum oxide blends grind lines fast and stays sharp over the life of the disc

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 4-1/2 in | 114.3 mm |

| Center Hole Diameter | 7/8 in | 22.225 mm |

Shipping Dimensions |

|

| Weight | 3.50006 lb |

|---|---|

| Length | 10.59055 in |

| Width | 10.59055 in |

| Height | 4.80315 in |

| Color | Pink |

|---|---|

| Maximum Speed | 13,000 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ Light Grinding and Blending Disc used for?

The Scotch-Brite™ Light Grinding and Blending Disc is specifically designed to help grind, blend and finish all types of metals in one step.

-

How rough or coarse is the Heavy Duty A Coarse disc?

This particular variant of our light grinding disc range has an aggressive abrasive capability that makes it ideal for materials with tough defects. It uses a ceramic abrasive grain which enables fast cuts while still maintaining a uniform finish.

-

What size are these discs? Are they sold individually or as part of a pack?

These discs have a diameter of 4-1/2 inches by 7/8 inches. They are sold in cases consisting of fifty individual discs per case.

-

Is there any special consideration I need to make when using this product so that my workpieces don't get damaged during processing?

. Yes, indeed there is! One key difference between our traditional abrasives solutions and this particular option lies on how much heat generated from friction can be managed during its application process. To avoid scorching your substrates you should keep the disc moving; try not to apply excessive pressure; regulate rotational speed optimally (depending upon material thickness), make use regular dresser cleaning schedule's etc. All whilst adhering to your companies PPE standards & recommendations laid out within Occupational Health & Safety guidelines specific for your region/country/state yaddah yaddah...

Scotch-Brite™ Light Grinding and Blending Disc

The Scotch-Brite™ Light Grinding and Blending Disc is a versatile tool that allows you to blend and prep for paint in a single step, providing both a high cut rate and excellent blending ability.

With its durable construction, these discs are designed to withstand heavy-duty applications on mild steel, ensuring they hold up even under tough conditions.

Specifically engineered for superior mild steel surface conditioning, the Scotch-Brite™ Light Grinding and Blending Disc offers a smoother and more efficient grinding, blending, refining, or deburring experience.