| SKU | 7000045864 |

|---|---|

| Legacy SKU | 61500013166 |

| UPC | 00048011074948 |

| Product Number | 07494 |

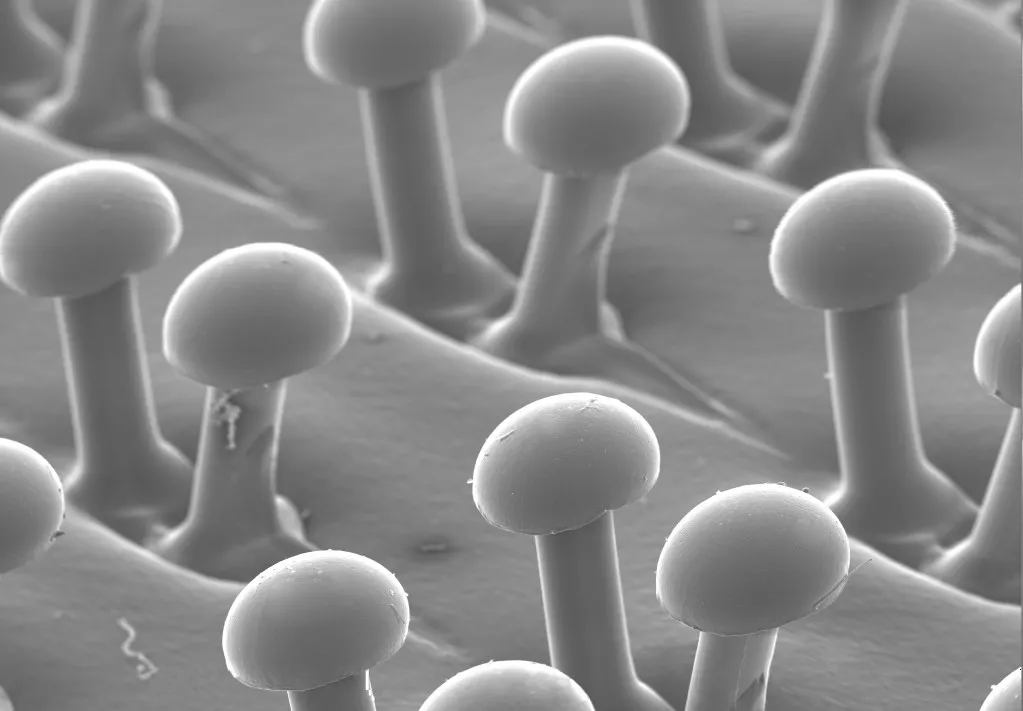

The Scotch-Brite Disc Pad is an abrasive accessory that helps connect Scotch-Brite Surface Conditioning Discs to right angle grinders with ease. The center pin, which centers the disc on the pad, does not extend past the surface of the disc when the disc is installed. Together with the Scotch-Brite abrasive disc, this back up pad works well on metals, paints and sealants.

- Center pin back up pad connects center-hole Scotch-Brite™ Surface Conditioning Discs (sold separately) to power tools

- Center pin is specially designed to not interfere with work surfaces, minimizing risk of scratching or gouging

- Center pin enables well centered disc attachment, which reduces vibration and increases operator comfort

- Use with right angle grinder

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2 in | 50.8 mm |

| Thickness | 0.12 in | 3.04 mm |

Shipping Dimensions |

|

| Weight | 0.6 lb |

|---|---|

| Length | 6 in |

| Width | 6 in |

| Height | 4 in |

| Color | Black |

|---|---|

| Maximum Speed | 23,000 mps |

PRODUCT FAQ

-

What is the 3M™ Disc Pad Holder 922 used for?

The 3M™ Disc Pad Holder 922 is specifically designed to securely hold a variety of discs in place. It has a firm rotary action and allows for easy attachment to power tools with its quarter inch shank.

-

How many pieces come in one case of the product?

One case of the product contains ten pieces, which gives you multiple holders and ensures that you have enough on hand when needed.

-

What type of material do we use for making this pad holder?

Our disc pad holder is made from high-quality materials that are sturdy, durable and long-lasting. This ensures users receive great value even if it's frequently used.

-

Does it work well with any project or just specific ones?

:The 2-inch size fits comfortably on all types of sanding and grinding projects. Whether you need fast removal or finer finishing, our disc pad holder can tackle various applications efficiently.

-

Is it easy to install/mount onto other tools?

The quarter-inch shank is compatible with most drills and electric grinders; hence installation doesn't take much effort or time at all--it's quite simple!

Using the Scotch-Brite™ Disc Pad is as simple as threading the pad onto the power tool and then attaching the disc to the pad face. The center pin system contributes to a reduction in hand-arm vibration due to its ability to repeatedly and accurately center the disc on the pad, in comparison to other pads without the center pin feature.

The Scotch-Brite™ Surface Conditioning Discs are made with aluminum oxide or other abrasive minerals and are available in a variety of grades. These discs are commonly used to remove rust, discoloration, and residual sealants. They help clean flat metal parts, prep surfaces after weld seam removal and prep surfaces prior to coating or painting.

The reason these discs can prep surfaces so well is because they strike a balance between cut and finish. The abrasive mineral cuts burrs and contaminants while the spongy open web responds to surface imperfections without gouging, marring or damaging the base material. The non-woven, open web, durable construction is designed to resist loading; gaps between fibers allow debris to escape and not clog the disc. Consequently, the service life of the disc increases.

3M engineered this comprehensive system of abrasive accessories and discs to make your work swift and efficient. 3M makes engineering innovative abrasive products their top priority, so you can focus on what matters to you: high-quality work.

Features:- Center pin system reduces hand-arm vibration

- Available in a variety of grades

- Preps surfaces without gouging, marring or damaging the base material

- Non-woven, open web, durable construction resists loading

- Comprehensive system of abrasive accessories and discs

- Easy to use

- Removes rust, discoloration, and residual sealants

- Cleans flat metal parts

- Preps surfaces after weld seam removal and prior to coating or painting

- Increases service life of the disc

- Makes work swift and efficient

- Allows you to focus on high-quality work