| SKU | 7000028479 |

|---|---|

| Legacy SKU | 61500122546 |

| UPC | 00048011137438 |

| Product Number | XL-UW |

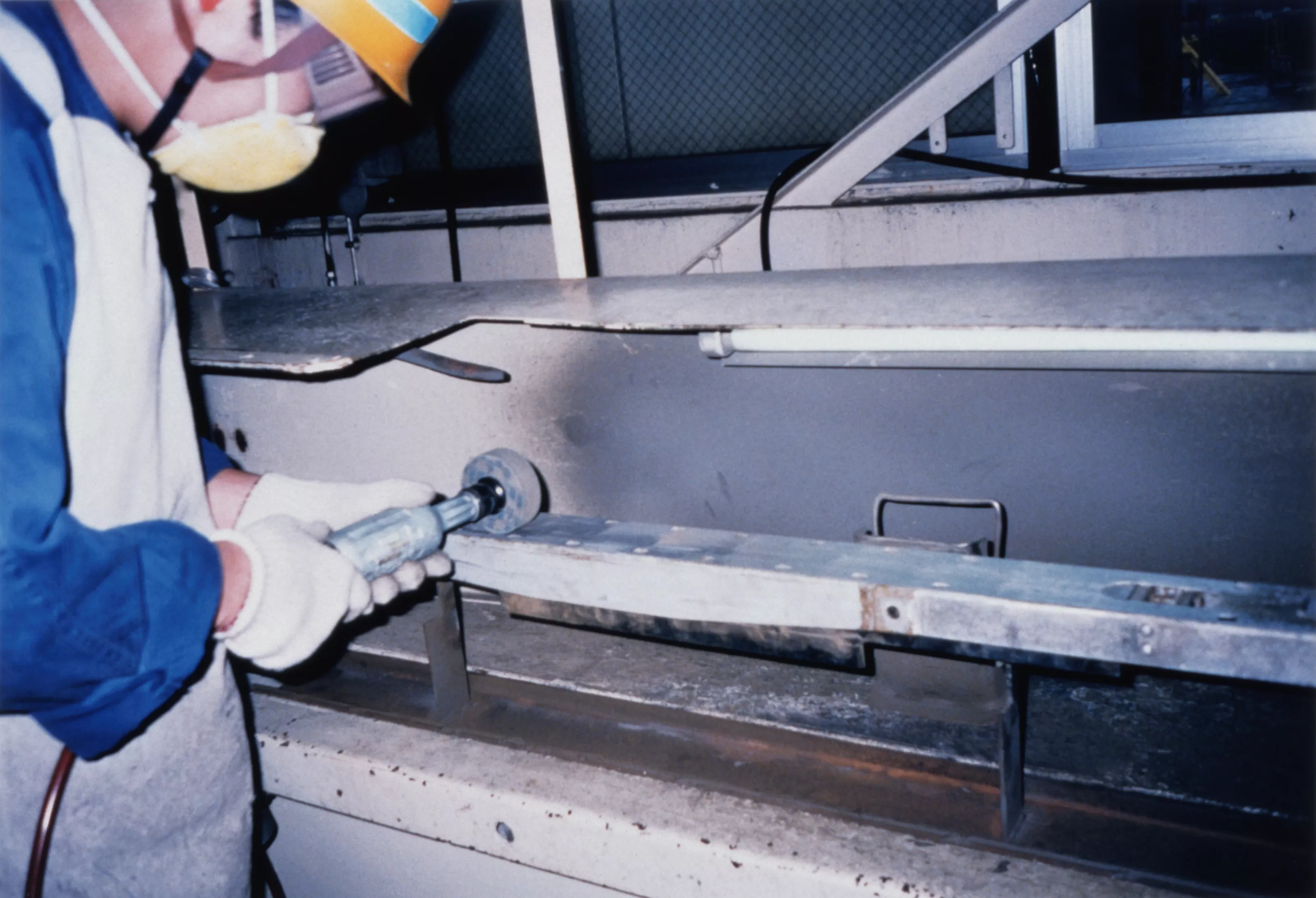

Scotch-Brite EXL Unitized Wheels feature a soft, conformable consistency that effectively smooths, deburrs and finishes the edges of metal alloys, as well as many plastics and composites. There are a variety of densities and grades starting from a very soft 2 density for applications requiring conformability to a hard, aggressive 8 density for maximum cut and durability.

- Wheel edge can be dressed for effective deburring, finishing and polishing of all metal alloys and many plastics and composites

- Tough, layered, unitized construction can operate clockwise or counterclockwise directions

- Conformability allows abrasive to stay in contact with complex-shaped parts in robotic processing

- Densities and grades ranging from soft and conformable to hard and aggressive offer utility for a wide variety of applications

- Resists smearing for cleaner surfaces and less preparation

- Minimizes heat build-up to lessen impact on heat-sensitive materials

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 6 in | 152.4 mm |

| Center Hole Diameter | 1 in | 25.4 mm |

Shipping Dimensions |

|

| Weight | 1.04984 lb |

|---|---|

| Length | 6.69291 in |

| Width | 6.69291 in |

| Height | 3.07087 in |

| Color | Gray |

|---|---|

| Maximum Speed | 5,000 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite EXL Unitized Wheel XL-UW made of?

The wheel is made with a tough web material that has been impregnated with aluminum oxide particles.

-

How does this wheel perform compared to other abrasive wheels?

The EXL Unitized Wheel delivers consistent cut and finish performance throughout its life. This makes it ideal for working on hard metals like stainless steel, as well as softer materials like plastics and composites.

-

How long will these wheels last in use?

The lifespan of each wheel depends on many factors such as the users' application technique, workpiece material/stability and duration/ frequency of use but generally customers can expect them to last longer than coated abrasives because they have fewer attachment points between the abrasive mineral particles which means less loading-up.

-

. Can I safely stack multiple units of these wheels onto my tool spindle at once?

. Yes! 3M designed these unitized wheels to be used stacked or singly depending on your specific needs/preferences. But please ensure that you're using proper safety guards when running any grinding tools uwheels included even if they appear small; flying debris can cause injuries so always err on the side of caution!

Consistent Performance on a Variety of Substrates

The Scotch-Brite™ EXL Unitized Wheel is designed to provide a clean edge without smearing, which reduces the need for additional clean up and preparation. It is optimized for use on a die grinder, minimizing heat buildup during operation, making it ideal for use on heat-sensitive materials. This wheel is filled with abrasive minerals that quickly smooth edges of metal, plastic, and composites. It is available in fine, medium, coarse, and extra coarse grades with aluminum oxide, and very fine and fine grades with silicon carbide.

Ideal for Robotic Deburring

Scotch-Brite™ EXL Unitized Wheel is an excellent option for robotic deburring due to its wide range of conformability options and high consistency. It quickly removes burrs and sharp edges in end-of-arm tooling operations, delivering consistent performance through the full life of the abrasive. Scotch-Brite™ offers unique surface conditioning products with abrasives incorporated into nonwoven nylon fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results over the life of the product. The open-web material is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the nylon fibers.