| SKU | 7000000879 |

|---|---|

| Legacy SKU | 62374898302 |

| UPC | 00021200825842 |

| Catalog Number | 3748 TC |

| Product Number | 3748-TC |

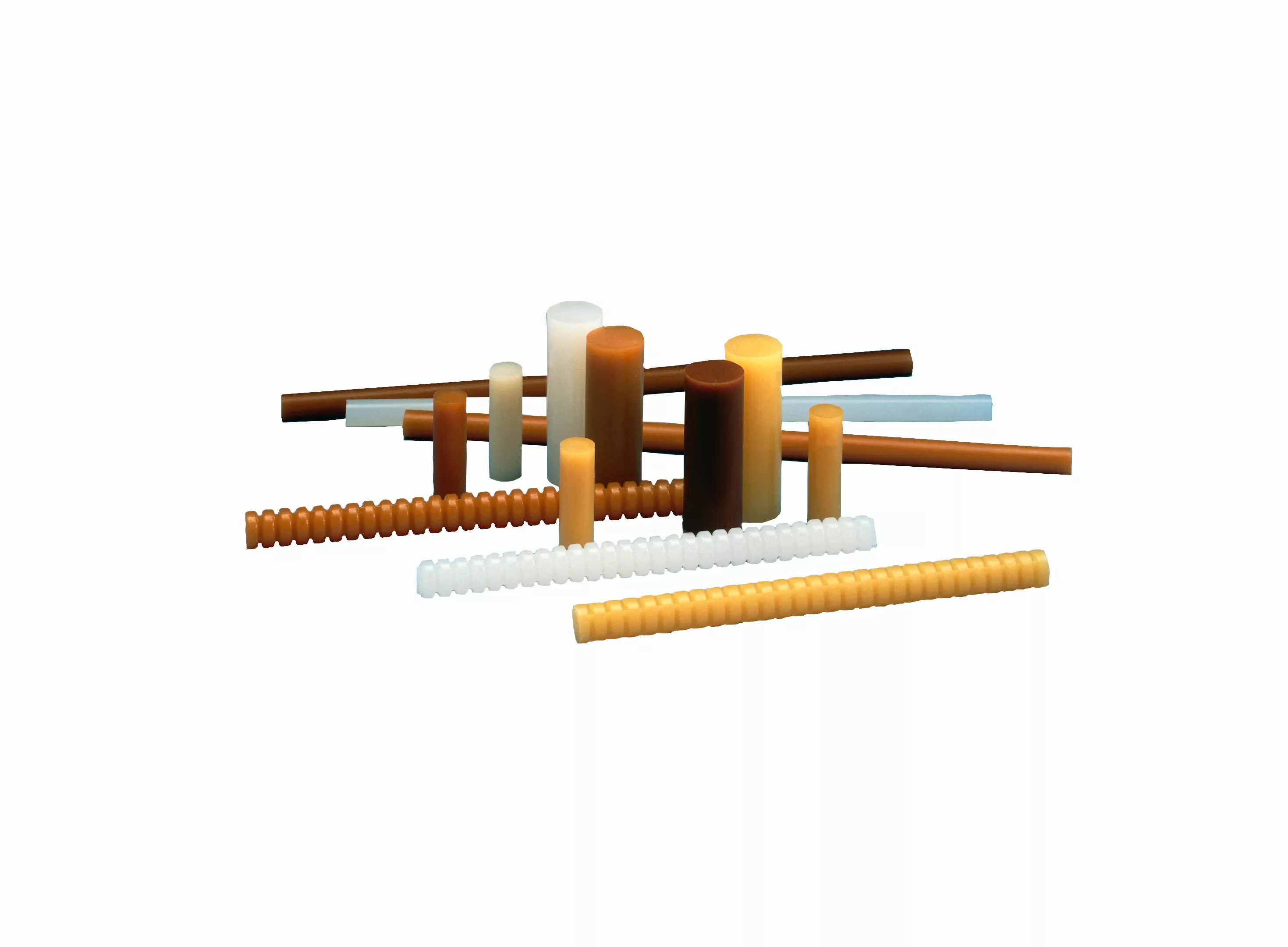

3M Hot Melt Adhesive 3748 is a tough, flexible hot melt adhesive with exceptional low temperature thermal shock properties that is able to provide optimal adhesion in fluctuating temperatures. As a 100% solids thermoplastic resin, this hot melt adhesive offers excellent durability for a wide variety of applications.

- High temperature performance and thermal shock resistance

- Formulated for bonding low surface energy plastics and coatings to dissimilar materials

- High peel delivers long-term strength and durability

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 11.77048 lb |

|---|---|

| Length | 8.11024 in |

| Width | 7.51969 in |

| Height | 12.24409 in |

| Color | Off-white |

|---|

PRODUCT FAQ

-

What are the key features of 3M™ Hot Melt Adhesive 3748TC?

The key features of our 3M™ Hot Melt Adhesive 3748TC include its strong adhesion, fast set time, and excellent heat resistance.

-

What materials can be bonded with this hot melt adhesive?

Our Off-White 5/8 in x 2 in,11 lb case is ideal for bonding a range of substrates including foam plastics (polyurethane) metal and other low surface energy materials.

-

How do I use this hot melt adhesive product?

Applying the adhesive is easy-- simply heat up your preferred applicator gun to around '375 degrees F' and apply it. Once applied enough pressure must be added while bonding as well to ensure maximum performance.

3M™ Hot Melt Adhesive 3748 provides good resistance to heat, impact, fuel and oil. It is manufactured using 100% solids, thermoplastic resin for use with a 3M™ Hot Melt Applicator. This adhesive provides high temperature stability 175°F / 79°C with a 25-second open time that is sufficient for fit positioning and adjusting. 3M™ Hot Melt Adhesive 3748 will bond wood, polypropylene, electronics, vinyl and lightweight substrates on furniture, automotive interiors, outdoor applications, small appliances and general product assembly.

Recommended Applications- Transportation interiors

- Seating attachment

- General product assembly

Hot melt adhesives, also known as glue sticks, are liquefied thermoplastic adhesives available in both low and high-temperature versions. Low temperature hot melt adhesives are applied at 250ºF/121ºC temperatures, which makes them ideal for bonding electronics, plastics, cloth and other heat sensitive materials. High temperature hot melt adhesives are applied at 380ºF/193ºC and produce a stronger bond than the low temperature hot melts.

Melted adhesive is extruded through a nozzle using a 3M Hot Melt Applicator by either pneumatic pressure, a mechanical trigger mechanism, or with pressure applied directly on the stick. Different nozzles can be used to apply thin, wide strips or narrow, thicker beads. Hot melt adhesive generally sets quickly, ranging from a few seconds to a few minutes, depending on the adhesive formulation.

Bringing Better Ideas to the Surface through Science and Innovation3M Industrial Adhesives and Tapes Division applies the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, these technologies help customers deliver competitive products to the market faster and more efficiently.