| SKU | 7100322371 |

|---|---|

| Legacy SKU | 70009159446 |

| UPC | 00076308426446 |

| Catalog Number | BRKIT-2PK-ES |

| Product Number | BRKIT-2PK-ES |

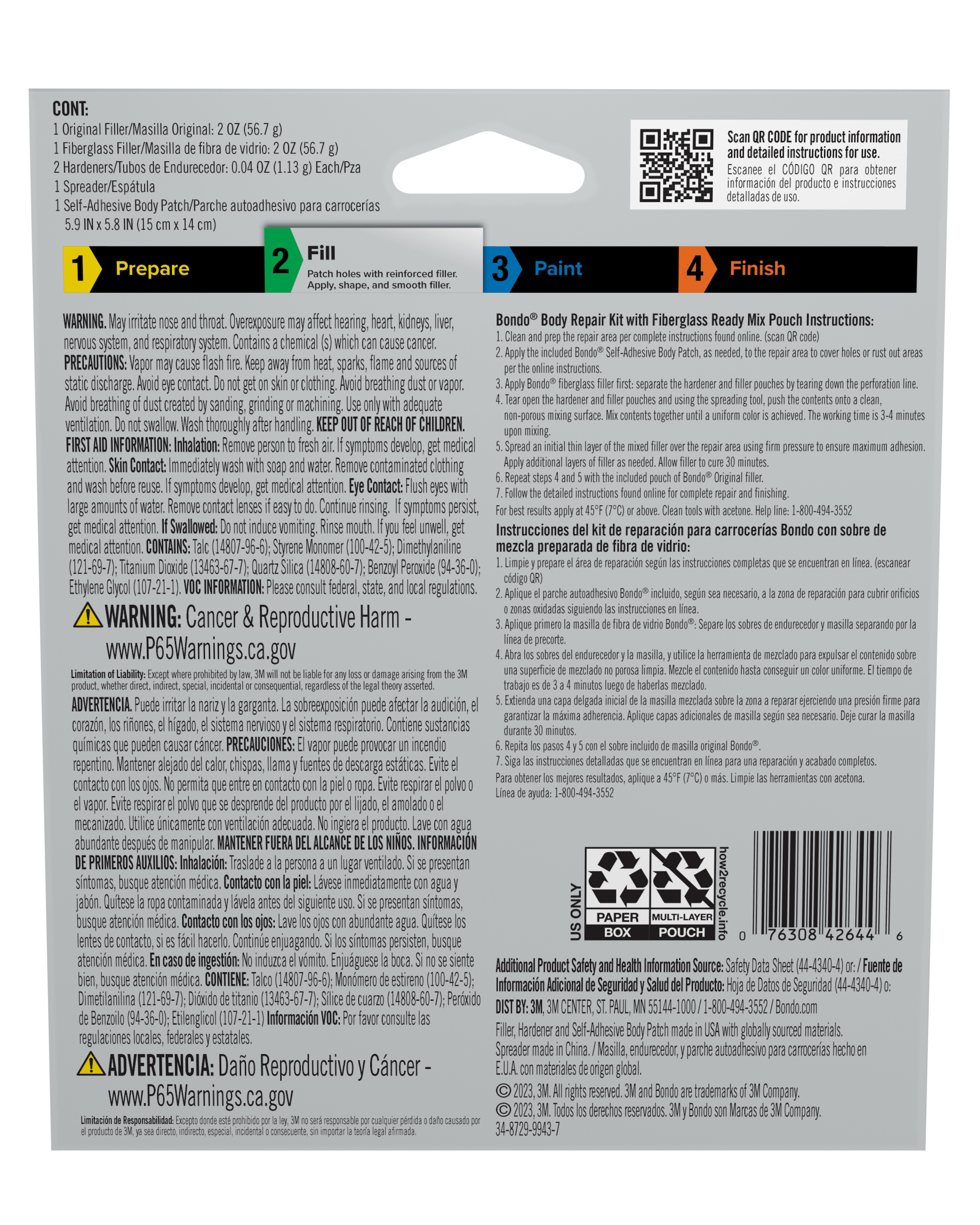

This Bondo Body Repair Kit contains everything you need to make same day repairs to dents, rust holes up to 3", scratches, and more on vehicle bodies and panels. Along with step-by-step instructions, this kit contains two ready-mix pouches (Bondo Original and Bondo Fiberglass), self-adhesive body patch, and spreader. These pre-measured packets offer a hassle-free application process, ensuring accurate proportions for optimal results. This fast-curing kit shapes in minutes and is specially formulated to be non-shrinking, providing a seamless and durable finish for your repairs.

Bondo Body Repair Kit Ready Mix Pouch Directions:

1) Clean all surfaces with soap and water followed by a low VOC compliant cleaner. Allow to dry.

2) If repairing fiberglass, sand the damaged area with 80 grit sandpaper or a 36 grit disc. Cut damaged or cracked pieces of fiberglass away with a saw blade. Sand the area 1 beyond the repair to roughen the surface. Clean again with a low VOC compliant cleaner. If repairing metal, sand with 80 grit sandpaper to remove all paint, primer, and rust down to bare metal. Sand 1-2 inches beyond damaged area. Clean again with a low VOC compliant cleaner.

3) Apply the included Bondo Self Adhesive Body Patch to the repair area to cover holes or rust out areas larger than in diameter, cutting to size as needed. Overlap the opening with the screen by 1 on all sides.

4) Use the Bondo Fiberglass filler pouch first. Separate the hardener and filler pouches by tearing down the perforation line.

5) Knead the filler pouch and hardener pouch to ensure components are ready for use.

6) Tear the filler pouch open and use the spreading tool to push the entire pouch contents onto a non-porous mixing surface.

7) Tear the hardener pouch open and use the spreading tool to push the entire pouch contents onto the non-porous mixing surface next to the filler.

8) Use spreading tool to mix hardener and filler components together to achieve a uniform color. When product is mixed, the working time is 3-4 minutes.

9) Spread an initial thin layer of the mixed fiberglass filler over the repair area using firm pressure to ensure maximum adhesion. Apply additional layers of fiberglass filler as needed. Allow the fiberglass filler to cure 30 minutes.

10) Rough shape the fiberglass filler with 80 grit sandpaper as needed. Repeat steps 5 through 8 using the Bondo Original Filler pouch, applying a topcoat of this material over the area repaired with fiberglass filler. Allow 20 minutes to cure.

11) Rough shape the filler as needed with 80 grit sandpaper and final finish with 180 grit or finer. Featheredge the repair. Wait 45 minutes and apply 2-3 coats of primer to cover the repair area.

12) Apply Bondo Glazing and Spot Putty to fill in small imperfections and re-prime with 2-3 coats. Follow paint manufacturers recommendation for priming and final finishing.

For best results apply at 45F (7C) or above. Clean tools with acetone or lacquer thinner. Help line: 1-800-494-3552

- EVERYTHING YOU NEED to fill holes and rust-outs on your vehicle or boat

- READY MIX POUCHES include the original 2-part formula of filler and hardener

- SAVE TIME with guess-free, ready-mix pouches that eliminate the need to measure filler and hardener

- DIY BODY REPAIR KIT fixes automotive rust out and holes up to 3" wide

- TWO-PART TECHNOLOGY chemically bonds to the surface for permanent repair

- KIT CONTENTS INCLUDE Bondo Original Filler and Hardener Pouch, Fiberglass Filler and Hardener Pouch, self-adhesive body patch, and spreader

Product Dimensions |

Imperial | Metric |

| Weight | 0.62001 lbs | |

|---|---|---|

| Width | 6.3748 | |

| Length | 0.8748 | |

| Height | 6-3/4 |

Shipping Dimensions |

|

| Weight | 3.72008 lb |

|---|---|

| Length | 7.00787 in |

| Width | 5.86614 in |

| Height | 8.50394 in |

PRODUCT FAQ

-

How many pouches come in a case of 3M's Bondo® Body Repair Kit BRKIT-2PK-ES?

Each case contains 6 ready-to-mix pouches.

-

Is the Bondo® Body Repair Kit easy to use for beginners?

Yes, the kit is designed to be user-friendly and suitable for both DIY enthusiasts and professionals.

-

What size are the individual pouches in this repair kit?

Each pouch holds 2 oz of ready mix material for convenient application on small repairs.

-

Can this product be used on all types of vehicles, including metal and fiberglass surfaces?

Yes, the Bondo® Body Repair Kit is versatile and can be applied on various surfaces commonly found in automotive repair projects.

-

Are there any color options available for the Bondo® Body Repair Kit BRKIT-2PK-ES?

The kit comes as a standard gray shade that can be easily painted over to match your vehicle's finish after application.

The Bondo Body Repair Kit is a comprehensive solution for making same day repairs to dents, rust holes up to 3 inches, scratches, and more on vehicle bodies and panels. This kit includes step-by-step instructions and all the necessary materials for a hassle-free application process.

The kit contains two ready-mix pouches: Bondo Original and Bondo Fiberglass. These pre-measured packets ensure accurate proportions for optimal results. The Bondo Original pouch is specially formulated to be non-shrinking, providing a seamless and durable finish for your repairs.

In addition to the ready-mix pouches, the kit also includes a self-adhesive body patch and a spreader. The self-adhesive body patch is used to cover holes or rust out areas larger than in diameter. It can be easily cut to size as needed. The spreader is used to apply the filler materials onto the repair area.

The Bondo Fiberglass filler pouch is used first in the repair process. The hardener and filler pouches are separated by tearing down the perforation line. The filler pouch is then kneaded to ensure the components are ready for use. The contents of the filler pouch are pushed onto a non-porous mixing surface using the spreading tool. The hardener pouch is also torn open and its contents are mixed with the filler components to achieve a uniform color. The working time for the mixed product is 3-4 minutes. An initial thin layer of the mixed fiberglass filler is spread over the repair area using firm pressure. Additional layers can be applied as needed. The fiberglass filler is allowed to cure for 30 minutes.

After rough shaping the fiberglass filler with 80 grit sandpaper, the Bondo Original Filler pouch is used for the topcoat. The same mixing process is followed, and the Bondo Original Filler is applied over the area repaired with the fiberglass filler. This topcoat is allowed to cure for 20 minutes.

Once the filler has cured, it can be further shaped and finished using 80 grit sandpaper and 180 grit or finer sandpaper. The repair area is featheredged for a seamless blend. After waiting 45 minutes, 2-3 coats of primer are applied to cover the repair area. Any small imperfections can be filled with Bondo Glazing and Spot Putty, followed by another round of priming and final finishing according to the paint manufacturer's recommendation.

For best results, it is recommended to apply the Bondo Body Repair Kit at temperatures of 45°F (7°C) or above. Tools can be cleaned with acetone or lacquer thinner. If you have any questions or need assistance, please contact our help line at 1-800-494-3552.