| SKU | 7100159534 |

|---|---|

| Legacy SKU | 60440349383 |

| UPC | 00638060054963 |

| Product Number | 981F |

3M Cubitron II Cloth Belt 981F is an abrasive sanding belt for grinding, weld removal, finishing and blending. It is constructed on a tough, Y-weight backing with fast-cutting 3M Precision-Shaped Grain. The water-resistant material and cutting aide allow for use with liquid coolants to prevent loading when used on aluminum, bronze and brass.

- Designed to grind soft metal substrates like aluminum, brass and bronze as well as carbon steel and mild steel

- 3M Precision-Shaped Grain cuts exceptionally fast for grinding and finishing on a range of metals

- Integrated dry lubricant reduces loading when grinding soft metals

- Strong mineral adhesion for reduced shelling when grinding on the edge of the belt

- Tough, Y-weight polyester cloth backing holds up to finishing and aggressive grinding

- Water-resistant polyester material can be used with liquid coolants to reduce grinding temperatures

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 16.84 lb |

|---|---|

| Length | 16.08976 in |

| Width | 16.00984 in |

| Height | 4.75984 in |

| Color | Mahogany |

|---|

PRODUCT FAQ

-

What is the 3M™ Cubitron™ II Cloth Belt 981F made of?

The 3M™ Cubitron™ II Cloth Belt 981F is made of a hard, tough ceramic blend abrasive grain that provides high-performance material removal.

-

What size is the belt and how many come in a case?

The size of the belt is 2 x 72 in and there are 50 belts per case.

-

What weight or grade is this cloth belt?

This cloth belt has a YF-weight grade which means it’s suitable for heavy-duty sanding applications

-

Is the film-lok attachment system compatible with most sanders?

Yes, Film-lok makes these belts ideal for use on machines like inline sanders, as well as bench grinders with backstand attachments

-

Is this product versatile enough to be used on all types of materials surfaces?

Absolutely! Our Cubitron II abrasives work great on everything from metalworking to woodworking because they stay cooler and require less pressure than standard abrasives.

3M™ Cubitron™ II Cloth Belt 981F is a revolutionary product designed to solve three common problems associated with grinding and finishing aluminum and other soft metals. These problems include abrasive loading, edge-shelling, and operator fatigue.

To reduce loading when working with aluminum, bronze, and brass, a dry lubricant is integrated into the abrasive. This allows the abrasive grain to be relatively free from metal coating, which keeps the cutting surface of the mineral effective. The waterproof backing also enables the user to rinse areas of the workpiece and the cloth during use, in case the abrasive begins to clog.

3M™ Cubitron™ II Cloth Belt 981F features a durable, Y-weight polyester cloth backing that stands up to the stresses of working on gates, parting lines, and flashing in tight spaces. This helps prevent edge-shelling. Additionally, this cloth grinding belt features a proprietary resin system to improve mineral adhesion, further reducing the chances of shelling.

Worker fatigue can be a concern when grinding softer substrates. 3M™ Cubitron™ II Cloth Belt 981F grinds efficiently, and 3M Precision-Shaped Grain can allow the operator to cut with less pressure, which may help to reduce physical exertion on an operator.

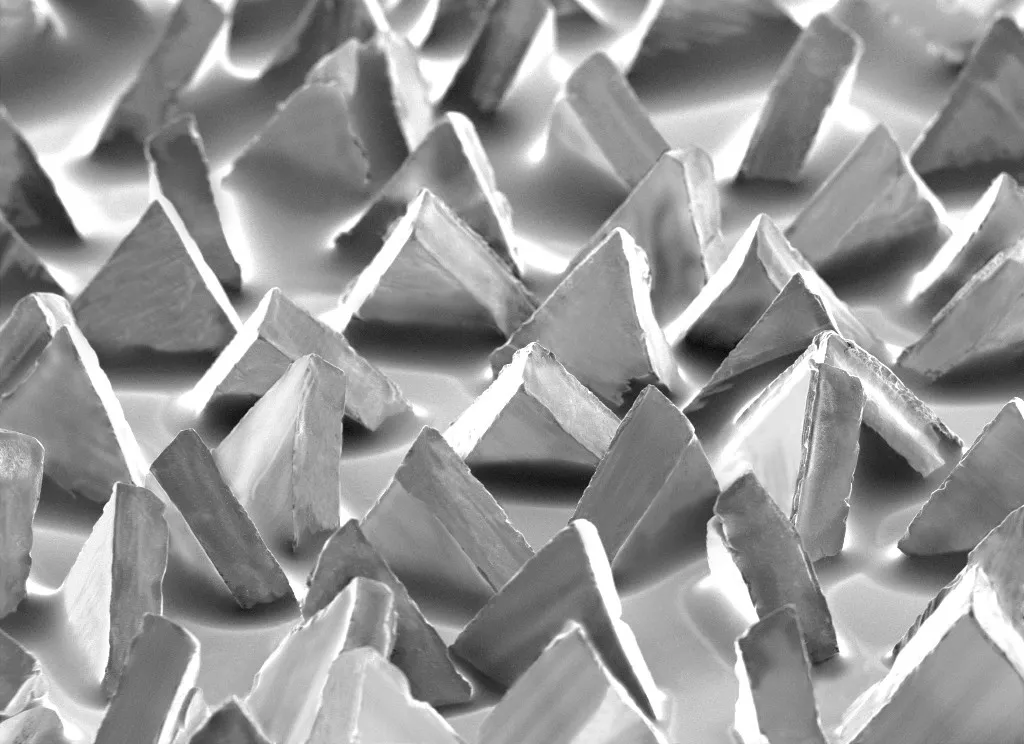

About 3M Precision-Shaped Grain3M Precision-Shaped Grain is the advanced technology behind 3M™ Cubitron II™ products. Its sharp, triangular structures continually fracture into sharp points and edges that slice cleanly through the substrate, rather than gouging or plowing as traditional abrasives do. This creates a fast cut and minimizes heat build-up in the workpiece, reducing heat-related defects. Moreover, because the abrasive itself stays cooler and sharper, it lasts significantly longer than conventional abrasive belts, decreasing the number of belt changeovers to lower operational costs. Its closed coat construction features a dense spread of abrasive grains across the surface of the cloth, cutting fast and providing a consistent finish.

Applications and Machine Types- Gate grinding

- Flashing removal

- Parting line removal

- Deburring

- Finishing

- Backstand grinders

- Stroke sanding

- Small bench grinders

- In-line sanders

- File belts