| SKU | 7100076925 |

|---|---|

| Legacy SKU | 60440256547 |

| UPC | 00051141542560 |

| Catalog Number | 7100076925 |

| Product Number | 947A |

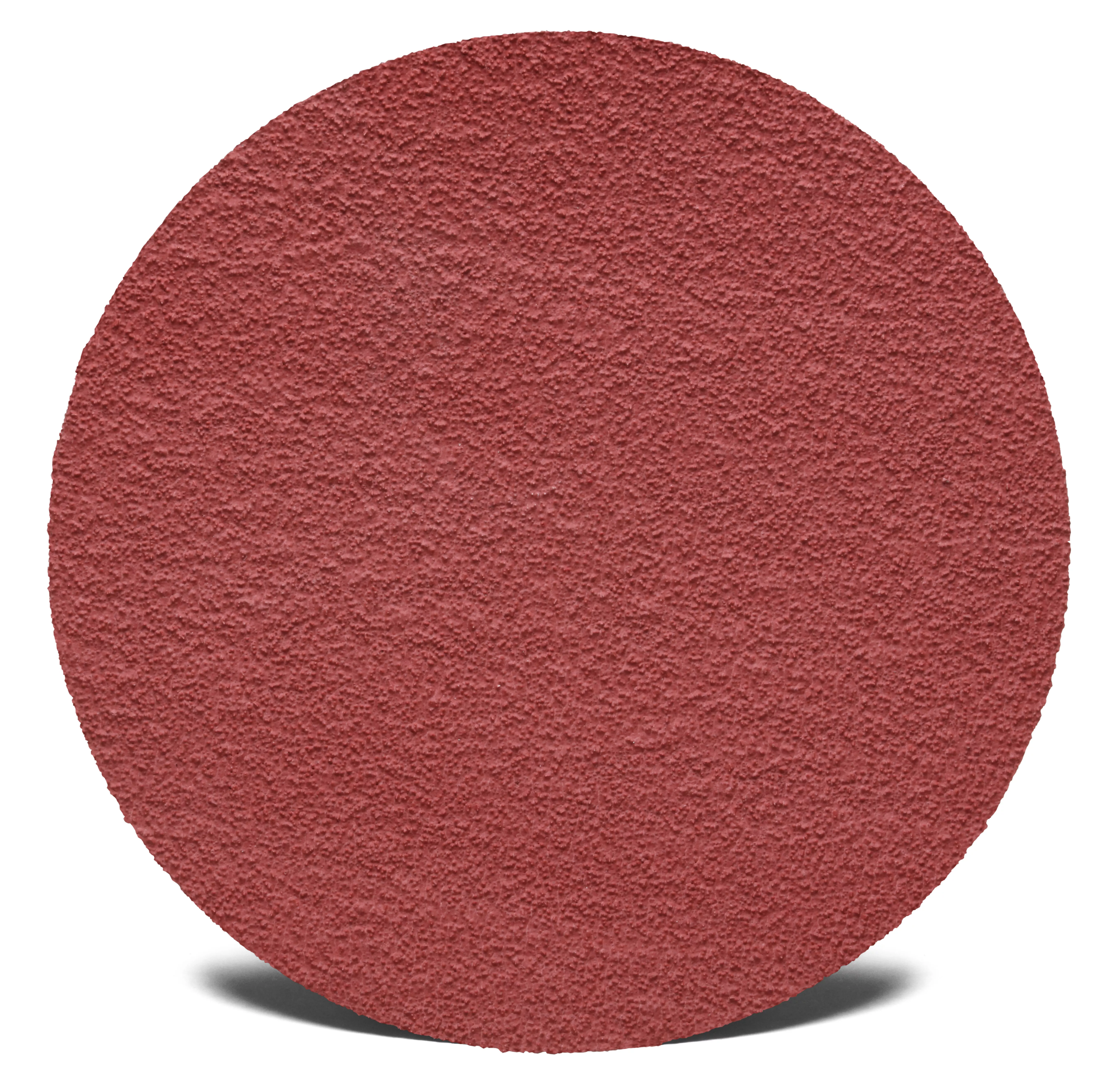

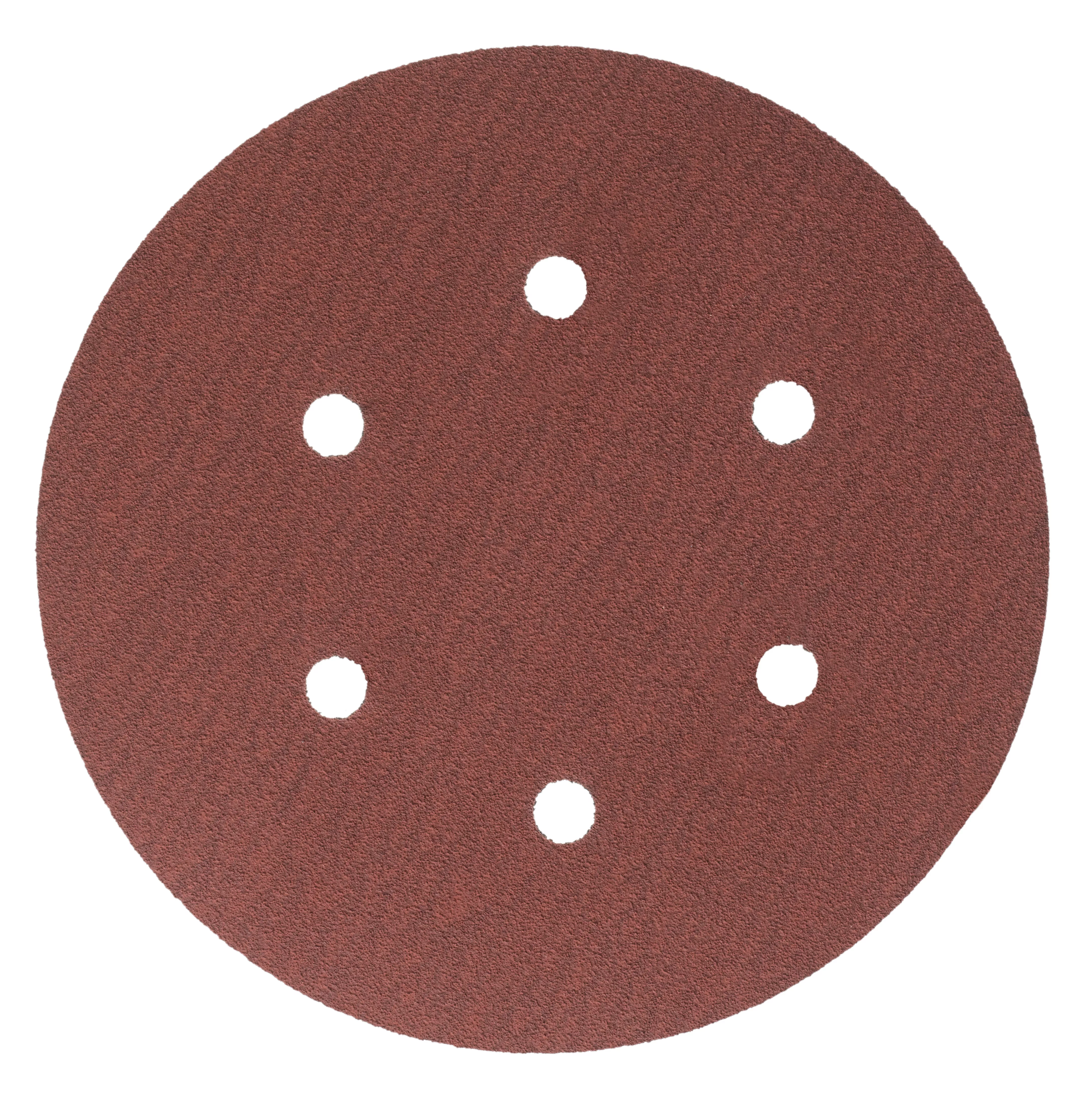

3M Cubitron II Roloc Durable Edge Disc 947A has a name that precedes it. This disc reflects the benefits of Cubitron II and Roloc products coupling the sharp, consistent cutting action of Cubitron II discs with an easy-to-use Roloc attachment. Built for durability and strength, it's great for edge work, because it stands up to edges without tattering or fraying.

- 3M Precision-Shaped Grain delivers sharp, cool, consistent cutting action

- Evenly-spaced grain features gaps that help debris escape, bolstering abrasive's ability to resist loading

- Poly-cotton backing offers great tensile strength, helping enhance overall abrasive durability

- Heavy X-weight backing does not wear and tear easily, rendering the disc a good match for edgework

- Roloc™ attachment makes disc to tool attachment swift and easy

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2 in | 50.8 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 2.45 lb |

|---|---|

| Length | 9.72441 in |

| Width | 9.13386 in |

| Height | 5.07874 in |

| Color | Maroon |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 25,000 rpm |

PRODUCT FAQ

-

What is the 3M™ Cubitron™ II Roloc™ Durable Edge Disc?

The 3M™ Cubitron™ II Roloc™ Durable Edge Disc is an abrasive disc that features precision-shaped ceramic grain and a stiff, durable backing for high-pressure grinding applications.

-

What grade is the 3M™ Cubitron™ II Roloc™ Durable Edge Disc?

This disc has a grade of 80+ which means it's coarse enough to remove paint or rust yet fine enough to leave behind a smooth surface.

-

How many items are there in each case of the 3M™ CubitronTMII RolocTM Durable Edge Discs?

. There are 200 discs per case while each inner pack contains around fifty pieces.

-

. Can I use these discs on any surface?

. Yes, you can use this product on various surfaces including metal, composites, gel coats, and plastics with no loading issues even in difficult conditions like wet sanding or coolant-lubricated environments.

3M™ Cubitron™ II Roloc™ Durable Edge Disc 947A is a small-sized disc built for low- to medium-pressure applications that require edgework. Its small size makes it nimble and maneuverable, allowing operators to get in, over, and around intricate parts. The disc is designed to withstand wear from edges, thanks to its dual combination of backing and weight. The poly-cotton backing is a blend of polyester and cotton, making it more durable than cotton alone and offering good tensile strength with more water resistance. The disc's heavy-weight backing minimizes the likelihood of tearing.

3M Science, Applied with 3M Precision-Shaped Grain TechnologyThe 3M™ Cubitron™ II Roloc™ Durable Edge Disc 947A is engineered to cut fast, run cool, and last long. It features 3M Precision-Shaped Ceramic Grain, a revolutionary technology that features triangular shaped ceramic minerals. As those minerals wear during use, they fracture at angles that continually form sharp points. This allows the minerals to keep slicing through the substrate with ease, while helping the grain wear more evenly. The triangles are evenly spaced when adhered to the backing, and the gaps between them permit dust and debris to escape, minimizing loading. The disc is available in 40, 60, 80, and 120 grit, so operators can choose the grade most fitting for their application.

Roloc™ Attachment for Ease of UseThe 3M™ Cubitron™ II Roloc™ Durable Edge Disc 947A features a Roloc™ attachment system, designed to make disc-to-tool connections quicker, faster, and more efficient. This particular disc is available in a TSM (metal) or TR (plastic) attachment. With a simple 1/2 twist, operators can secure or detach a disc from a Roloc™ backup pad (sold separately). With the help of a Roloc™ attachment, operators may enhance overall productivity.

Altogether, 3M™ Cubitron™ II Roloc™ Durable Edge Disc 947A was designed with speed and durability in mind, engineered to give operators a faster, more consistent cut each and every time.