| SKU | 7000047211 |

|---|---|

| Legacy SKU | 66000134099 |

| UPC | 00051115371462 |

| Product Number | 727334 |

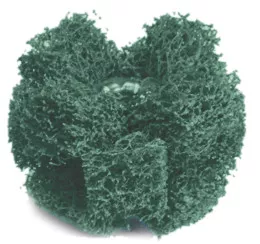

The Standard Abrasives Buff and Blend Cross Buff HS is uniquely designed to clean and polish hard-to-reach areas like the internal diameters of pipes and tubing. The Buff & Blend HS material allows removing surface contaminants without eliminating critical detail or gouging the workpiece.

- Unique abrasive design enables buff to fit inside hard-to-reach areas

- Open-web buff responds to surface imperfections with minimal gouging or marring of the substrate, sustaining part geometry

- Tough nylon face removes surface contaminants while resisting chatter or gouging of the workpiece

- Resin coated surface runs cool and is waterproof for use with lubricants

- Available in coarse (green) and medium (blue) abrasive grades to help produce satin finishes on soft metals

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 1 in | 25.4 mm |

Shipping Dimensions |

|

| Weight | 7.2488 lb |

|---|---|

| Length | 23.22835 in |

| Width | 9.6063 in |

| Height | 4.92126 in |

| Color | Green |

|---|---|

| Maximum Speed | 13,000 rpm |

PRODUCT FAQ

-

What is the Standard Abrasives™ Buff and Blend Cross Buff HS, 727334?

The Standard Abrasives™ Buff and Blend Cross Buff HS, 727334, is an abrasive product designed for blending small areas of a workpiece. It features a cross-shaped construction that allows easy access to hard-to-reach surfaces.

-

What is the size of this buff and blend product?

This particular buff and blend cross buff has dimensions of 1 inch x 3/8 inch with two ply layers. It also has an internally threaded steel reinforced brass bushing with an eight-32 thread size.

-

Is this product compatible with certain types of machines only?

This specific Standard Abrasives™ cross buff can be used on different tools such as rotary power sanders or grinders. However, users should make sure they use proper safety precautions while operating them.

-

Q: Does it come in bulk orders?

A: Yes, for customers who need larger quantities at once we offer them in cases containing 50 pieces per inner bag or case apart from them available individually upon request.

-

Q; What kind of abrasive material does it have?

A; The A/O Coarse type abrasive material delivers aggressive cut suitable for removing rusts , oxides, corrosion among other finishes on metal components

The Standard Abrasives™ Buff and Blend Cross Buff HS is the go-to product for stubborn surface areas that require a unique, tough construction. Unlike discs or wheels, the Cross Buff HS was designed to get inside narrow pipes or tubes. The abrasive fingers are spring-like and bend and move to accommodate the inner diameter of the workpiece. They refine deep scratches and defects without compromising the geometry of the part.

Quality Materials for the Toughest JobsBuff & Blend High Strength products are made from tough, resin-reinforced nylon fiber with aluminum oxide abrasive grain. The durable high strength construction of mounted cross buff provides aggressive action for the toughest applications and greater tear resistance, perfect for deburring or final finishing on irregularly shaped parts in tight spaces.

The abrasive material on the Cross Buff HS is a strong, all-purpose material for tough cleaning and polishing jobs. The aluminum oxide mineral cuts sharp while still delivering a fine polish. Cross Buff HS comes in both coarse and medium grades. Typically, a medium grade is useful when a soft scratch pattern is desired, whereas a coarse grade delivers a more aggressive scratch. Given its versatility, this abrasive is well-suited for removing surface oxidation, rust and surface coatings for part inspection, as well as surface preparation prior to coating. It can help remove corrosion on Steel Rule and Kirksite dies. It's also great for polishing round and square tubing, valve spools, molds, dies and inside diameters of lifter bores, valve bodies and brake cylinders.

Open Web DesignIn addition to the unique design of the Standard Abrasives™ Buff and Blend Cross Buff HS, the open web construction also adds a level of sponginess and flexibility. This open web material is created by combining nonwoven nylon strands and abrasive mineral with resin bonding material. Gaps between the nylon fibers allow unwanted swarf to escape, enhancing load resistance and efficiency. As the abrasive is less likely to clog with debris, the mineral keeps cutting sharper, longer.

The open web material resin bonding are also waterproof and can be used with lubricants, which help to keep the abrasive running cool and wash away swarf. The load-resistant properties of the web, combined with the swarf-cleaning action of the lubricant, help to prevent workpiece contamination. As debris clears away, the likelihood of particles smearing or blemishing the substrate decreases.