| SKU | 7000028143 |

|---|---|

| Legacy SKU | 60440124265 |

| UPC | 00051141205205 |

| Product Number | 466LA |

3M Trizact Hookit Film Disc Roll 466LA uses 3M microreplication technology to furnish small but mighty discs great for automotive workshops or spaces where coating repairs are common. These discs help to repair light defects, especially in automotive paint applications.

- 3M™ Trizact™ abrasives start sharp and stay sharp, resulting in more predictable finishes and improved, consistent results

- Roll form provides convenience and economy with 500 or more discs per roll

- Color coded by grade to help reduce risk for error during multi-grade sequences

- Silicon carbide mineral in three very fine micron grades

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 1-3/8 in | 34.925 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 1.24782 lb |

|---|---|

| Length | 8.85827 in |

| Width | 5.74803 in |

| Height | 6.06299 in |

| Color | Purple |

|---|---|

| Maximum Speed | 10,000 rpm |

PRODUCT FAQ

-

What is the 3M™ Trizact™ Hookit™ Film Disc 466LA used for?

The 3M™ Trizact™ Hookit™ Film Disc 466LA is designed for refining sand scratches and other surface defects in painted surfaces, gelcoat, and clear coats.

-

What grit size does the A7 represent on this disc?

The A7 on this disc represents a grit size of P3000.

-

How many discs come in each case of the 3M™ Trizact™ Hookit™ Film Disc 466LA?

Each case contains 2000 discs packaged in four inner boxes with each containing 500 discs.

-

Can I use this disc wet or dry?

This film disc can be used either wet or dry, depending on your preference.

-

Will these hook and loop perfectly onto any tool that uses a hook-and-loop backing pad?

. Yes! These Trizact film abrasive features our patented Hookit attachment system, which makes it easy to securely attach to most compatible hand tools that have a Velcro/Hook & Loop type backing pad.

3M™ Trizact™ Hookit™ Film Disc Roll 466LA is a versatile abrasive available in three grades: A3, A5, and A7. The abrasive is color-coded by grade to help reduce the likelihood of reaching for the wrong grade during a sequence.

The discs in the 3M™ Trizact™ Hookit™ Film Disc Roll 466LA are made with silicon carbide mineral. This synthetic mineral is very sharp and commonly used for low-pressure applications such as paint repair. While it breaks down faster than aluminum oxide, it produces a fine finish that's desirable when prepping or restoring surfaces.

Hookit™ Attachment3M™ Trizact™ Hookit™ Film Discs have hook and loop attachments on the back of the disc. Small tufts of fiber are pulled through scrim on the abrasive to create loops which, subsequently, attach to the hooks on Hook and Loop disc pads. These features make disc attachment, removal, and re-attachment swift and efficient. Moreover, they facilitate use and re-use of the disc for the extent of the abrasive life.

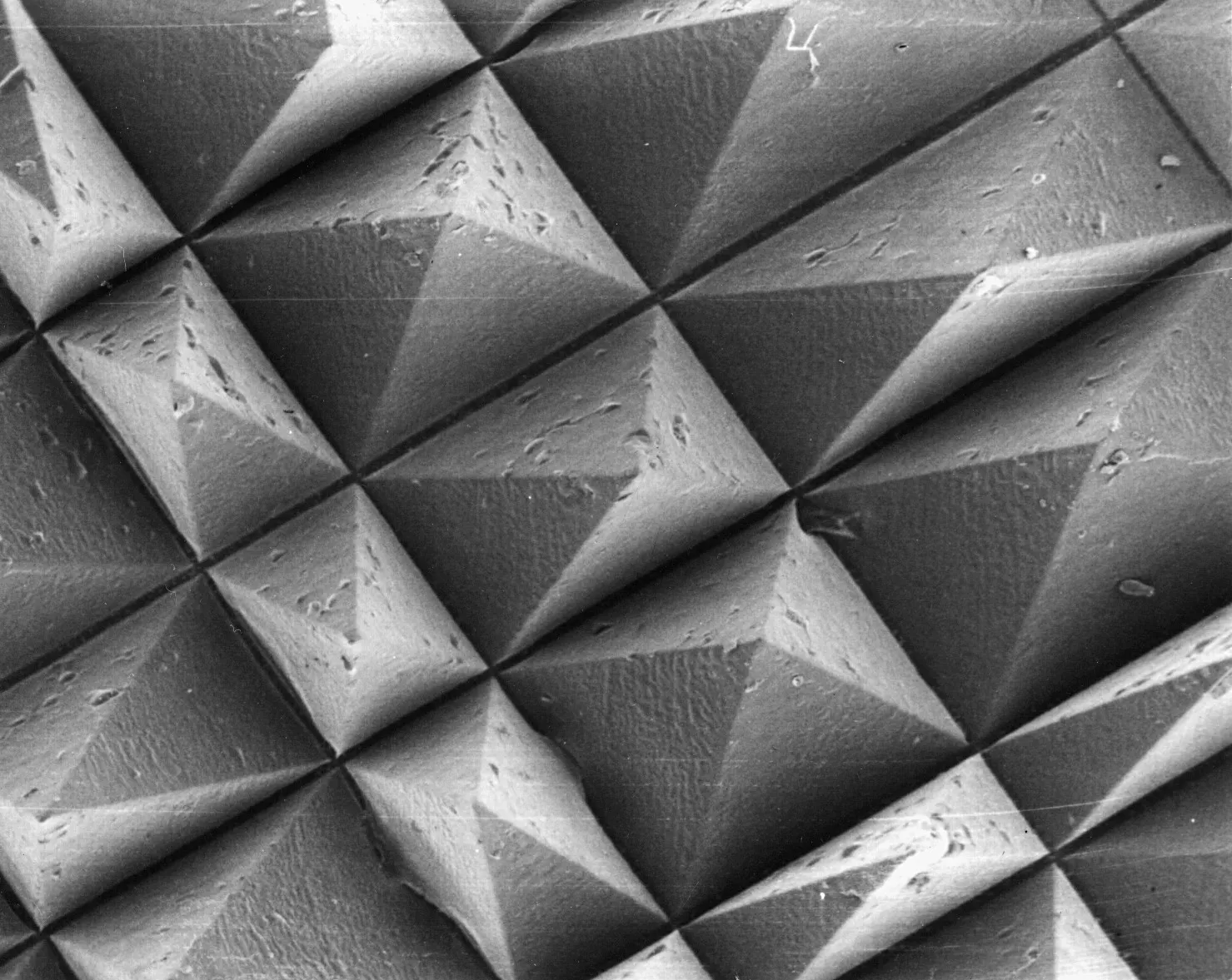

3M™ Science and the Power of Trizact™ Abrasives3M™ Trizact™ abrasives revitalize light dimensioning and finishing work by reducing processing steps, increasing throughput, and creating consistency. Big benefits are achieved through a 3M technology called microreplication. During microreplication, small three-dimensional structures resembling pyramids are adhered to a backing. These "pyramids" contain layers of mineral, and they begin to break down after repeated use, continually exposing fresh mineral.

The cycle of mineral renewal sustains the abrasive's sharpness. Ongoing sharp cutting action reduces the need to swap out the abrasive, contributing to higher throughput and increased productivity. Additionally, because mineral is uniformly distributed over the abrasive surface, the workpiece receives fixed – rather than erratic – contact for a consistent cut. From medical implants to surgical tools to automotive transmission components, 3M™ Trizact™ abrasives are uniquely suited for projects with acute technical requirements – delivering a consistent finish part after part.

- 3M™ Trizact™ Hookit™ Film Disc Roll 466LA is available in three grades: A3, A5, and A7.

- The abrasive is color-coded by grade to help reduce the likelihood of reaching for the wrong grade during a sequence.

- The discs in the 3M™ Trizact™ Hookit™ Film Disc Roll 466LA are made with silicon carbide mineral.

- 3M™ Trizact™ Hookit™ Film Discs have hook and loop attachments on the back of the disc.

- Small tufts of fiber are pulled through scrim on the abrasive to create loops which, subsequently, attach to the hooks on Hook and Loop disc pads.

- 3M™ Trizact™ abrasives revitalize light dimensioning and finishing work by reducing processing steps, increasing throughput, and creating consistency.

- Big benefits are achieved through a 3M technology called microreplication.

- The cycle of mineral renewal sustains the abrasive's sharpness.

- Ongoing sharp cutting action reduces the need to swap out the abrasive, contributing to higher throughput and increased productivity.

- Because mineral is uniformly distributed over the abrasive surface, the workpiece receives fixed – rather than erratic – contact for a consistent cut.

- 3M™ Trizact™ abrasives are uniquely suited for projects with acute technical requirements – delivering a consistent finish part after part.